Method for removing silicon from phosphogypsum in obverse floatation way under acidic condition

A technology of acidic conditions and phosphogypsum, applied in flotation, solid separation, etc., can solve the problems of cement products not up to standard, small scale of resource reuse, unstable product quality, etc., and achieve significant social and environmental benefits and low processing costs The effect of low cost and excellent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

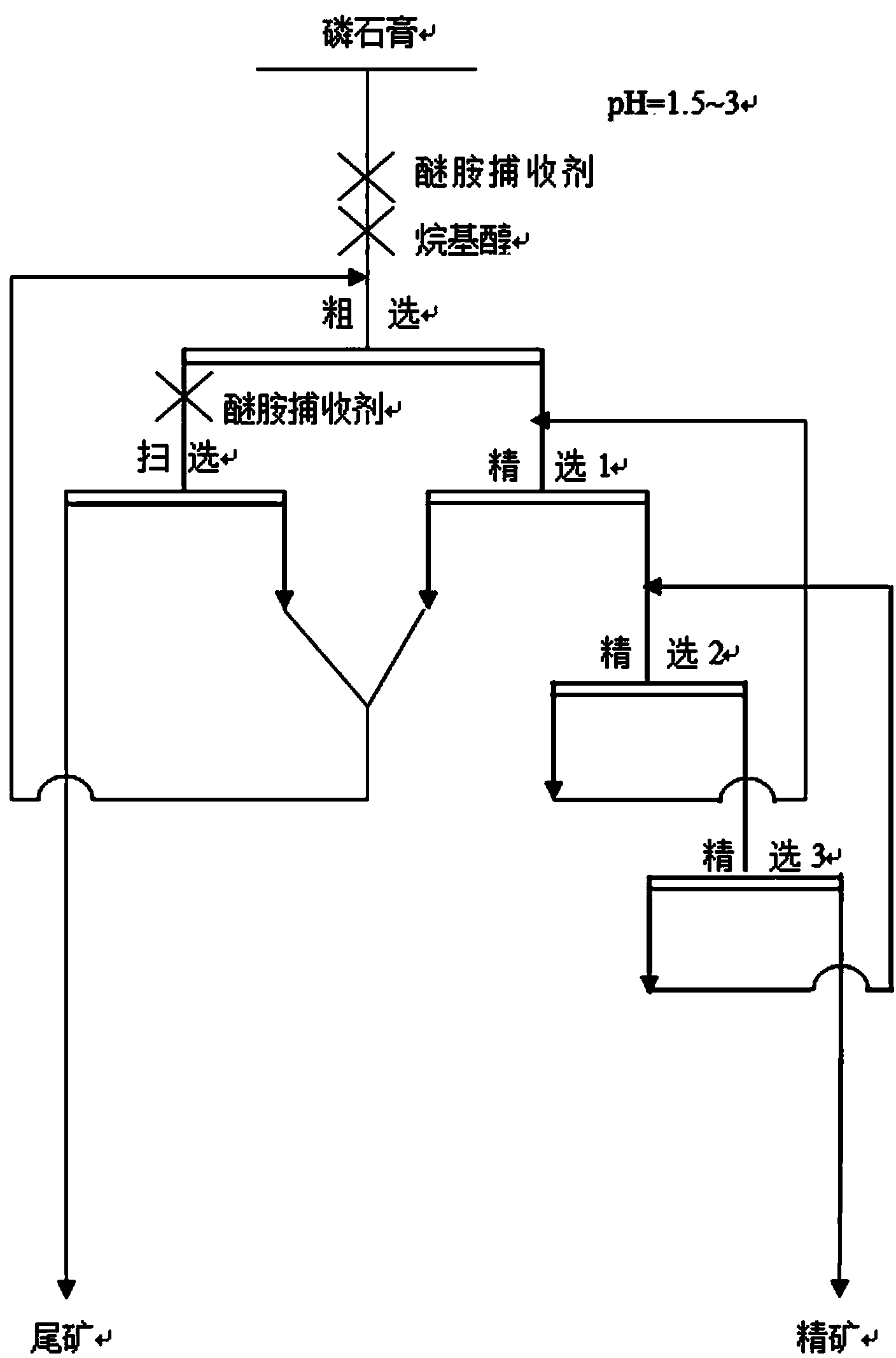

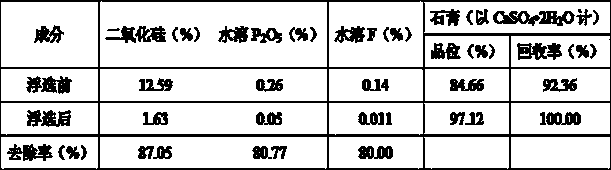

[0026] Example 1 : Phosphogypsum after three washings in the phosphoric acid production workshop of Furui Branch of Yuntianhua Group (see Table 1 for its composition), was added with Furui phosphogypsum stockyard pool water waste liquid to make the concentration of phosphogypsum slurry 30%, and dodecyl ether A 1% aqueous solution made of amine and lauryl alcohol is used as a flotation agent. The dosage of dodecyl ether amine is 250g / t, and the dosage of lauryl alcohol is 20g / t. The tank floatation is carried out under the conditions of pH=1.58 and temperature 20°C. Gypsum concentrate with a grade of 97.12% and a yield of 80.51% was obtained after one roughing, one sweeping and three beneficiations (see Table 1 for its composition).

[0027]

[0028] Table 1 Composition of phosphogypsum before and after desilication by flotation

[0029]

Embodiment 2

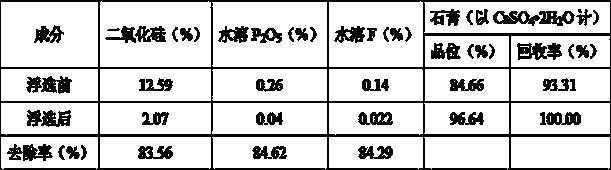

[0030] Example 2: Using phosphogypsum after three washings in the phosphoric acid production workshop of Furui Branch of Yuntianhua Group (see Table 2 for its composition), adding Furui phosphogypsum stockyard pool water waste liquid to make the concentration of phosphogypsum slurry 25%, adding lauryl ether A 2% aqueous solution made of amine and lauryl alcohol is used as a flotation agent, the dosage of dodecyl ether amine is 300g / t, the dosage of lauryl alcohol is 25g / t, and the tank floatation is carried out under the conditions of pH=1.83 and temperature 20℃ Gypsum concentrate with a grade of 96.64% and a yield of 81.74% was obtained after one roughing, one sweeping and two beneficiation (see Table 2 for its composition).

[0031] Table 2 Composition of phosphogypsum before and after desilication by flotation

[0032]

Embodiment 3

[0033] Example 3: Use the phosphogypsum after three washings in the phosphoric acid production workshop of Sanhuan Branch of Yuntianhua Group (see Table 3 for its composition), add Sanhuan phosphogypsum stockyard pond water waste liquid to make the concentration of phosphogypsum slurry 30%, and mix dedecyl ether amine, A 1% aqueous solution made of n-octanol is used as a flotation agent, the dosage of decanyl ether amine is 250g / t, the dosage of n-octanol is 25g / t, and the tank flotation is carried out under the conditions of pH=1.52 and temperature 20℃ , after one roughing, one sweeping and two beneficiation, a gypsum concentrate with a grade of 94.88% and a yield of 81.51% was obtained (see Table 3 for its composition).

[0034]

[0035] Table 3 Composition of phosphogypsum before and after flotation desilication

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com