A low-temperature circulating fluidized bed flue gas desulfurization and dust removal equipment

A technology of desulfurization and dust removal equipment and circulating fluidized bed, which is applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of easy condensation, uneven distribution of desulfurization agent, low mass transfer intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

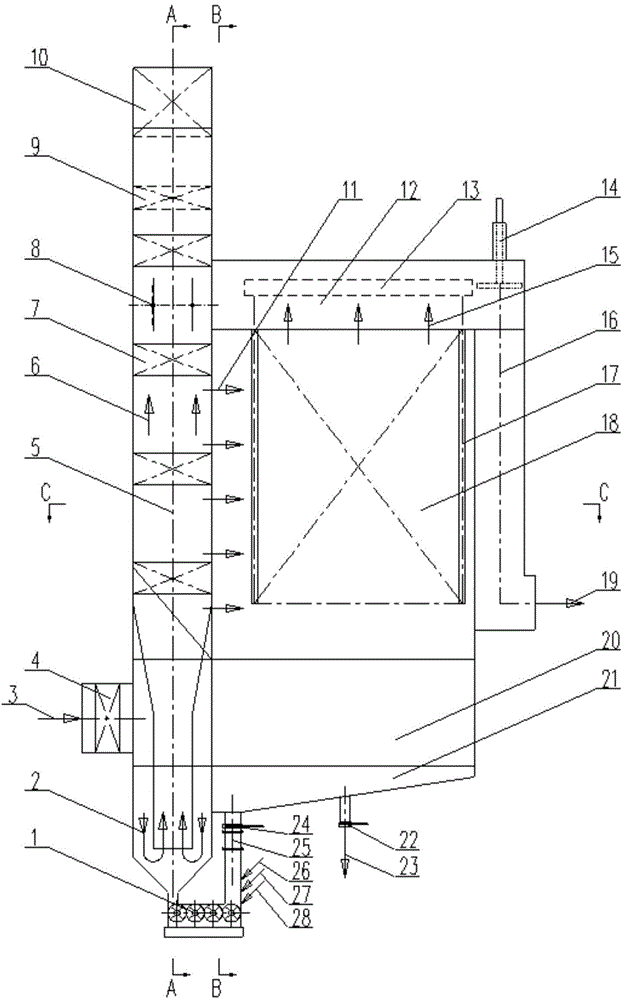

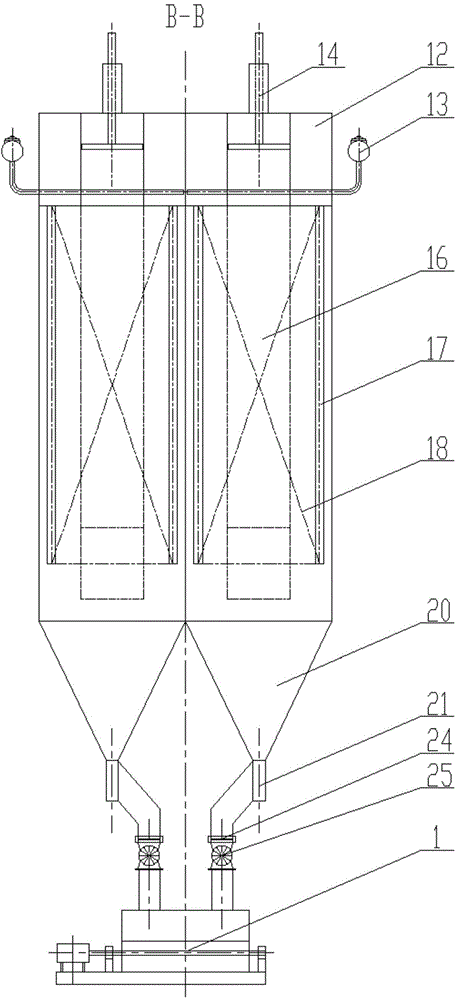

[0036] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0037] One of the obstacles to improving the efficiency of flue gas desulfurization equipment in the prior art is that when the adiabatic saturation temperature difference of desulfurization flue gas is small, condensation, scaling and bag sticking are easy to occur, which seriously affects the reliability of desulfurization equipment operation. The invention proposes a low-temperature circulating fluidized bed flue gas desulfurization and dust removal equipment capable of solving the above problems and improving the desulfurization efficiency under the premise of ensuring the reliability of the equipment operation.

[0038] Such as figure 1 Shown is a schematic structural diagram of the low-temperature circulating fluidized bed flue gas desulfurization and dust removal equipment, from which it can be seen that the equipment includes a desulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com