Inertial filter combined module for internal combustion and electric locomotives

A technology for electric locomotives and filters, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve the problems of inconvenient operation and maintenance of inertial filters, and achieve good overall assembly processability and application. Easy maintenance and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

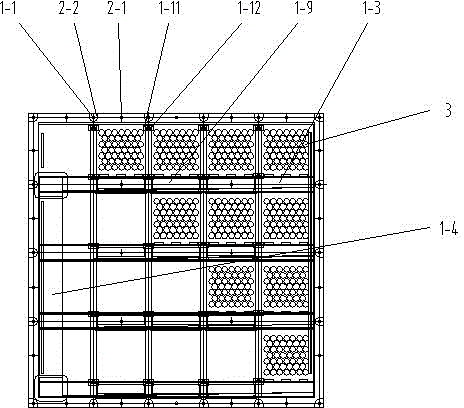

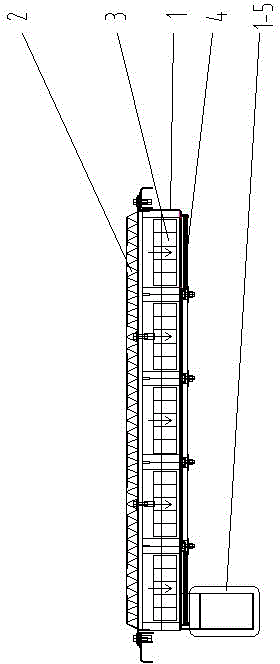

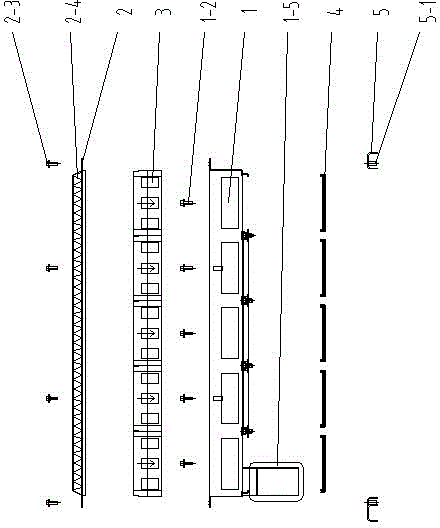

[0032] figure 1 A new type of inertial filter combination module structure for internal combustion and electric locomotives according to the embodiment shown in ~8, which consists of a filter rear cover 1 and a filter front cover 2 to connect a plurality of parallel inertial filters 3 sandwiched in the middle, the filter front cover 2 is provided with a V-shaped filter screen 2-4, and the filter rear cover 1 is provided with a fine filter assembly 4, thereby forming a three-stage filter combination module. In the filter back cover 1, each row of inertial filters 3 is provided with a dust exhaust duct branch pipe 1-3, which is connected with the dust exhaust duct main pipe 1-4, and passes through the dust exhaust duct flange 1-4 after summarization. 5 and its air exhaust duct seals 1-6 are connected with the air duct of the external dust exhaust fan to realize dust exhaust; the middle part of each dust exhaust air duct branch pipe 1-3 is provided with a plurality of dust exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com