High-image-quality wide-angle optical camera lens

A wide-angle optics and image quality technology, applied in the field of optical lenses, can solve the problems of low pixels, large dimensions, and large volume, and achieve the effect of good color reproduction, high sharpness, and clear colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

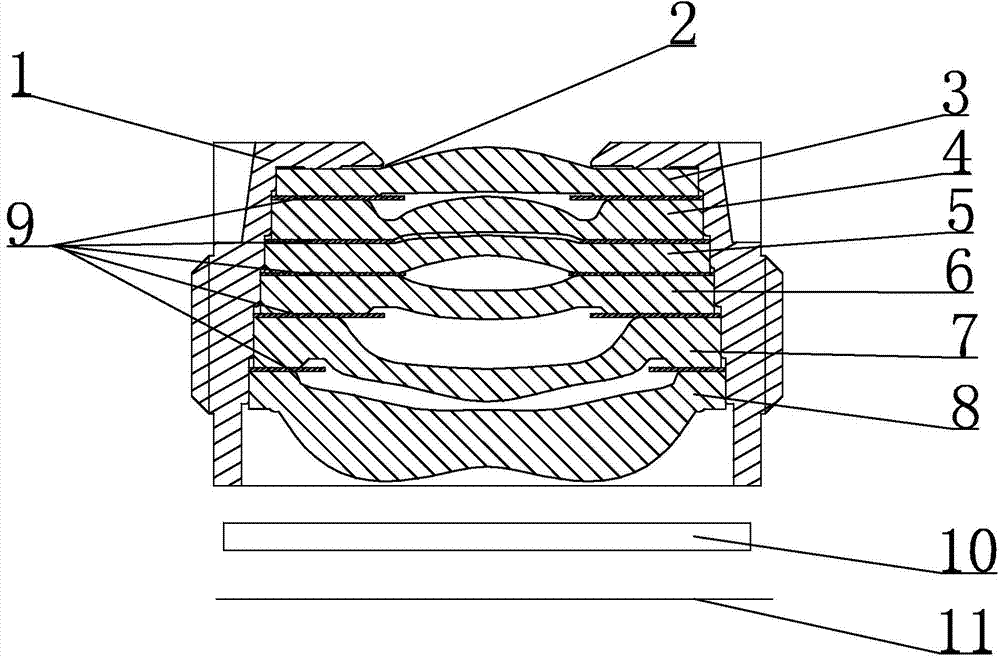

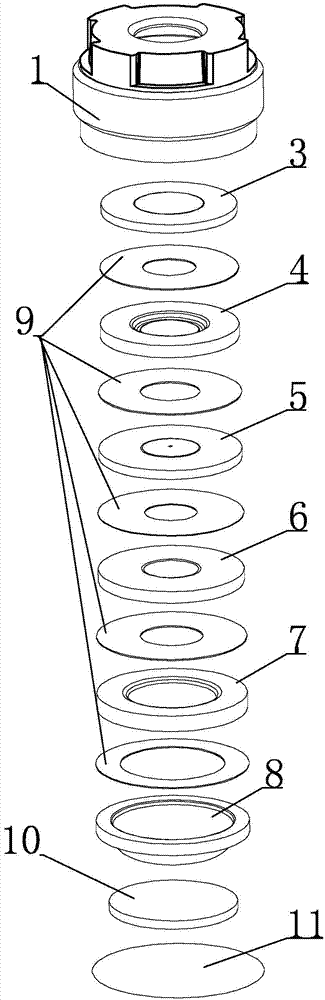

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

[0023] like figure 1 , 2 As shown, the high-quality wide-angle optical lens can be used for a relatively cheap high-pixel CMOS photosensitive film 11 , including a lens barrel 1 , and a mechanical aperture hole is arranged at the front end of the lens barrel to form an aperture 2 . A first lens 3 , a second lens 4 , a third lens 5 , a fourth lens 6 , a fifth lens 7 and a sixth lens 8 are sequentially arranged in the cavity of the lens barrel and behind the mechanical aperture. Spacers 9 are correspondingly provided between the adjacent lenses.

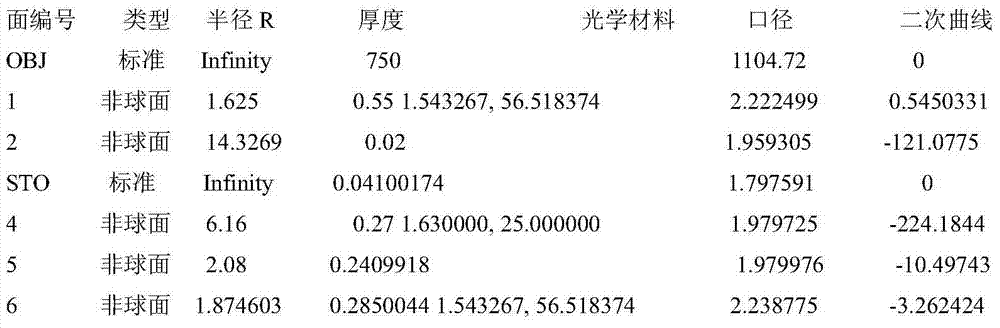

[0024] The first lens 3 is a positive focal length lens, the first surface 31 facing the object plane is an elliptical aspheric surface, and the second surface 32 facing the image plane is a hyperbolic aspheric surface. The two surfaces of the second lens 4 are meniscus-shaped negative focal length lenses, and both surfaces are hype...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com