A high-quality wide-angle optical system

A wide-angle optical system and image quality technology, applied in the field of optical lenses, can solve the problems of difficult product acquisition, long lens, large volume, etc., and achieve the effects of good color reproduction, cost reduction, and overall uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

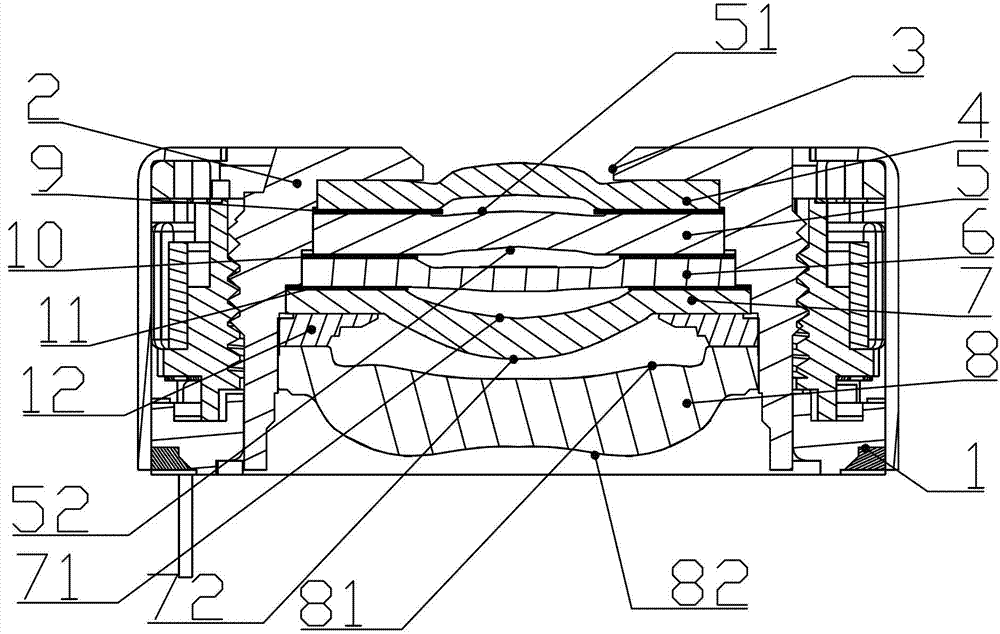

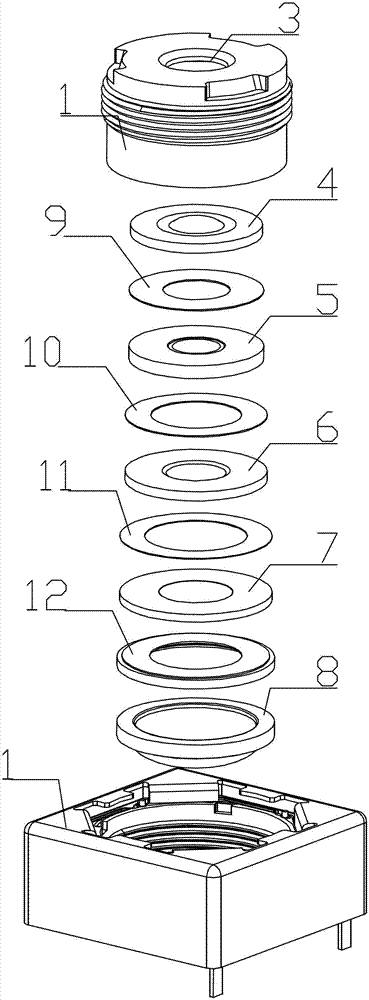

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

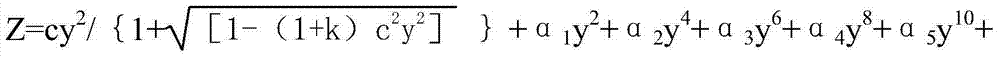

[0022] Such as figure 1 As shown, a high-quality wide-angle optical system can be used for relatively cheap high-pixel CMOS photosensitive sheets, including a seat 1 and a lens barrel 2 connected to the seat. In the cavity of the barrel 2, a first lens 4, a second lens 5, a third lens 6, a fourth lens 7, and a fifth lens 8 are arranged sequentially from outside to inside behind the diaphragm. A first spacer 9 is provided between the first lens 4 and the second lens 5, a spacer 10 is provided between the second lens 5 and the third lens 6, and a spacer 10 is provided between the third lens 6 and the fourth lens 7. There is a spacer 11 , and a spacer 12 is arranged between the fourth lens 7 and the fifth lens 8 . The first lens 4 is a positive focal length lens, both surfaces of which are oblate aspherical surfaces. The two surfaces of the second lens 5 are meniscus-shaped ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com