Water leakage detection mechanism

A detection mechanism, water body technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of excessively sensitive water pump seal failure, leakage, slowness, etc., to achieve the control method Variety, accurate conclusions, and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

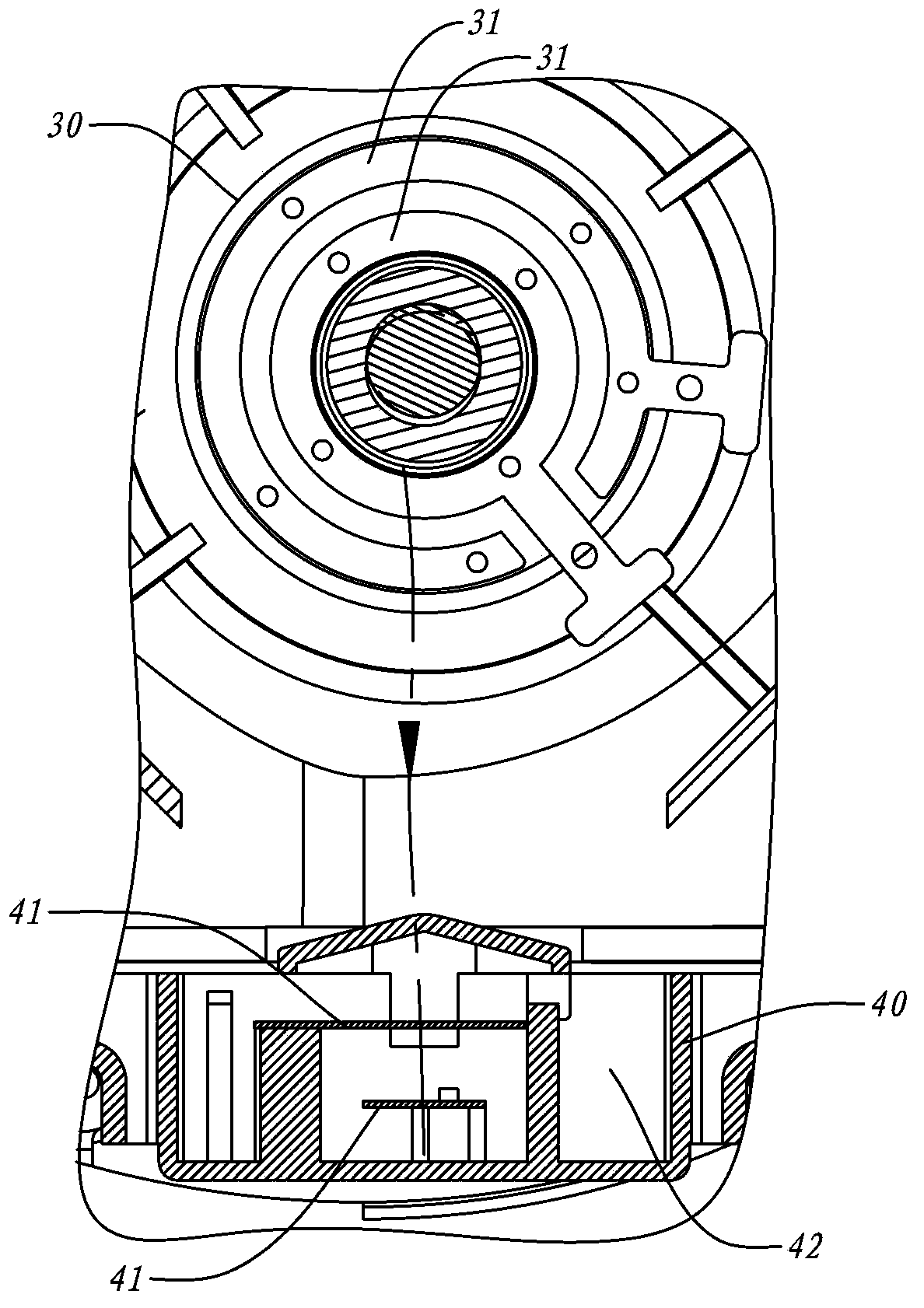

[0044] Such as Figure 1 to Figure 5 As shown, several schematic diagrams of Embodiment 1 of the water leakage detection mechanism of the present invention.

[0045] combine Figure 1 to Figure 3 , The present embodiment is a centrifugal water pump for a SPA pool. The drive shaft 11 of the pump body 20 is placed horizontally, so the drive component 10 (a motor in this example) and the pump body 20 are arranged in left and right rows. A frequency measuring probe 30 is fixed on the outer wall of the pump body 20 of the centrifugal water pump, the center of the bottom of the pump seat 21, that is, around the pump body 20 where the power shaft 11 of the water pump cooperates with the pump body 20, the frequency measuring probe has an exposed The water-touching surface is provided with a frequency-side electrode 31, and the frequency-measuring electrode 31 uses two conductive electrodes to detect water leakage. The position where the frequency measuring probe 30 is located is a ...

Embodiment 2

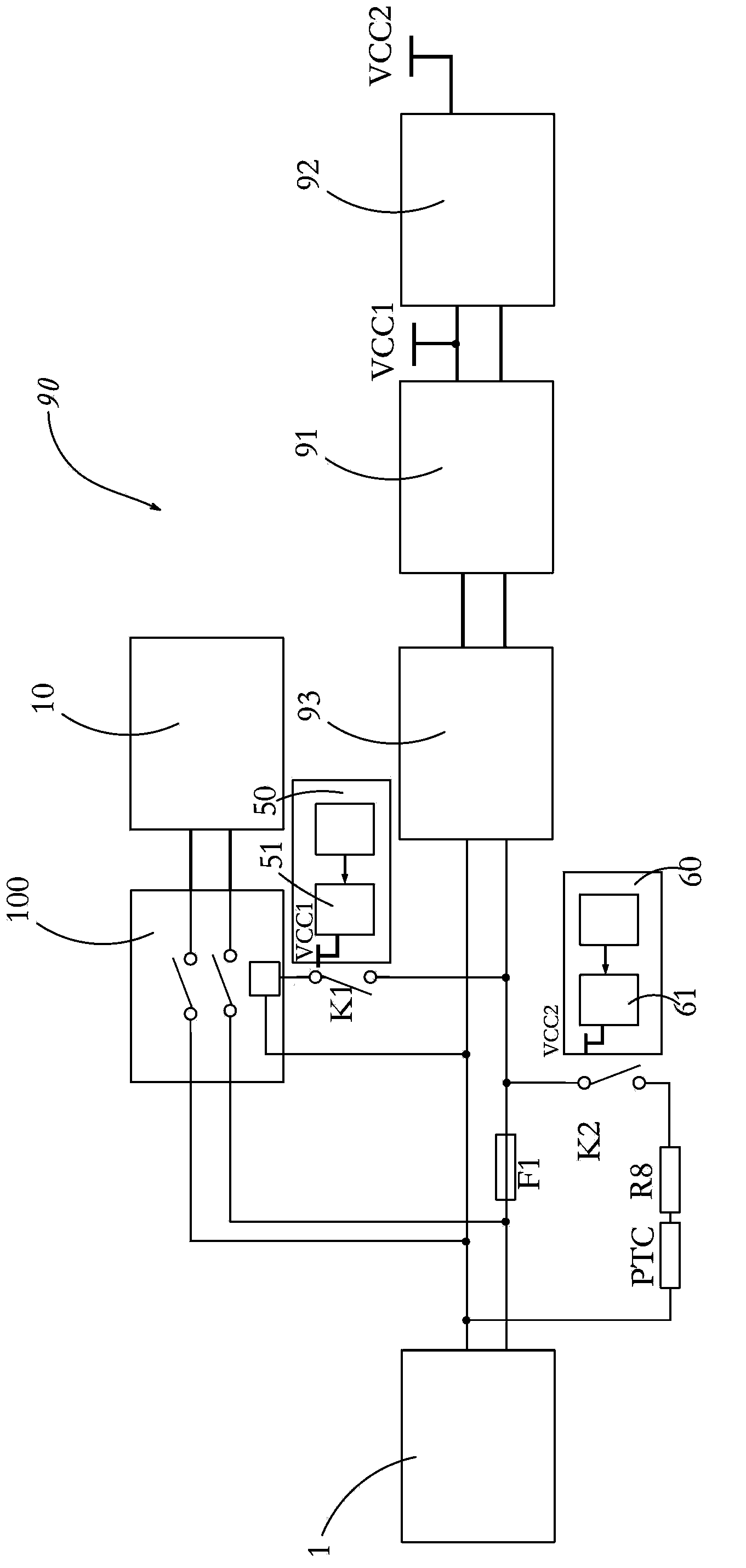

[0054] Such as Figure 6 Shown is a schematic diagram of Embodiment 2 of the present invention. The final driving part 10 of this embodiment is an AC motor, and the structure of the pump body 20 is the same as that of the first embodiment. The difference is in the control module 90 part. The control module 90 also includes a frequency test relay 51 and a single test relay 61, a power supply 1, a rectifier circuit 93, a first voltage stabilizing block 91 and a second voltage stabilizing block 92; this embodiment also includes a leakage protector 2 connected in series In the current loop of the entire control module 90 and the current loop (not marked) of the driving component 10; wherein, the on-off loop K1 of the frequency test relay 51 is connected in parallel with the on-off loop K2 of the single test relay 61, and is connected in parallel to the Between one AC input terminal of the leakage protector 2 and another AC output terminal of a different line—this scheme utilizes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com