Double-head steel structure vertical column

A steel structure and column technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of excessive construction waste, waste of raw materials, uncontrollable quality, etc., and achieve the effect of high building strength, no construction waste, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

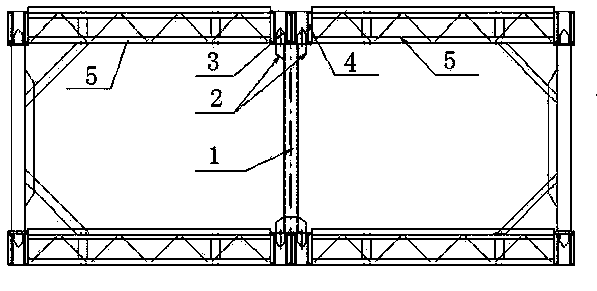

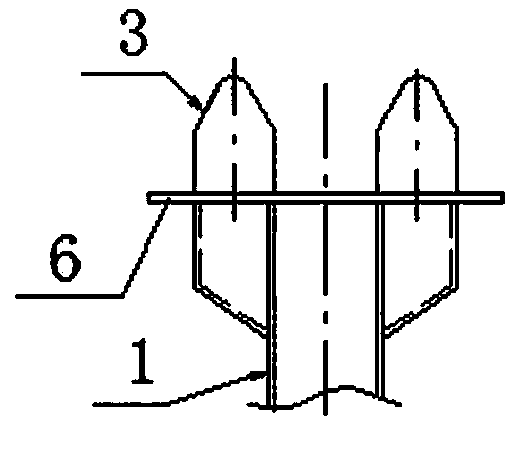

[0013] see figure 1 , figure 2 , image 3 , the double-headed steel structure column of the present invention has a corbel structure 2 protruding from both sides of the upper end and / or lower end of the steel structure column 1, and a double guide head 3 is fixed on the corbel structure 2.

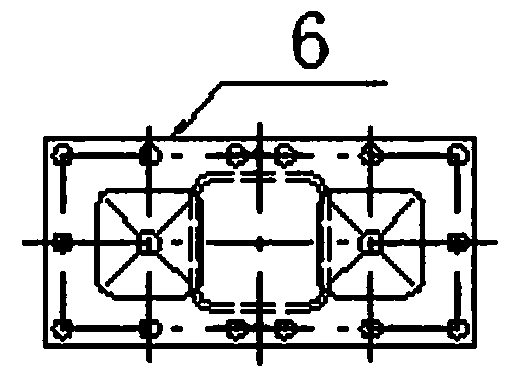

[0014] A column flange 6 is fixed on the upper end and / or lower corbel structure 2 of the above-mentioned steel structure column 1 , and the column flange 6 is flange-connected with the steel structure floors 5 on both sides of the column 1 .

[0015] The double guide heads 3 of the above-mentioned steel structure are respectively inserted into the guide pipes 4 on the floors on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com