Processing device for warp beam segmented dyeing

A technology of processing device and dyeing device, which is applied in textile processing machine accessories, textile material processing, textiles and papermaking, etc. It can solve the problems of low efficiency, serious color stains, low output, etc., and achieves small footprint and simple operation , unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

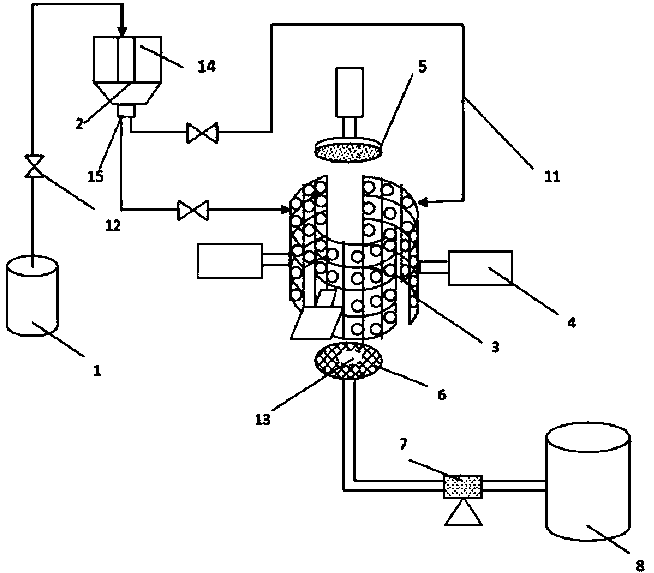

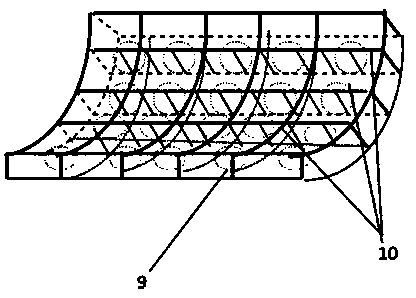

[0022] like figure 1 The processing device for beam section dyeing shown is composed of four parts: a dyeing system, a liquid supply system, a vacuum system and a control system, wherein: the dyeing system consists of an arc-shaped plate 3, a pressure telescopic arm 4, and an upper cover plate 5 It is composed of a chassis 6; the arc plate 3 and the upper cover plate 5 are fixedly connected with the movable end of the pressure telescopic arm 4. The inner wall of the arc-shaped plate 3 is provided with several prisms 10 arranged in a criss-cross pattern, such as figure 2 As shown, the inside of the curved plate 3 is divided into several dyeing cavities; the middle of the curved plate of each of the dyeing cavities ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com