Automatic overturning material discharging device

A technology of unloading device and automatic turning over, which is applied in the direction of packaging, emptying containers, bottle filling, etc. It can solve the problems of heavy labor, poor operating environment, channel blockage, etc., and achieve small labor, simple and reliable devices, The smooth effect of material conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

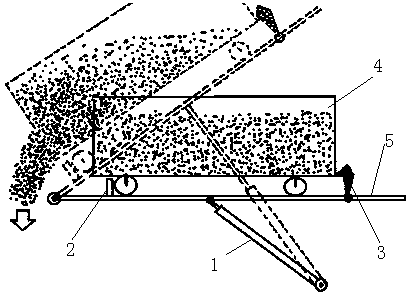

[0010] This invention has a magazine bracket 5, and one end of bracket 5 is equipped with hinge and links to each other with operating platform. The center of the bottom end of the bracket 5 is equipped with a hinge to connect the hydraulic push rod 1, and the bottom of the hydraulic push rod 1 is also connected to the platform by a hinge. There is anti-skid plate 2 at the front end of material box bracket 5, and a hinged lock 3 is arranged at the tail to prevent material box 4 from tipping over.

[0011] The extension and retraction of the hydraulic mandrel 1 can allow the bracket 5 to complete turning over and laying flat. The front end of the material box 4 is designed with a flashboard, which can be automatically discharged after being turned over by pulling out the flashboard. The front anti-skid plate 2 of the bracket 5 and the lock 3 at the rear end can prevent the material box 4 from sliding and overturning on the bracket 5, while the anti-skid plate 2 has the functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com