Continuous conveyer for asphalt mixture

A technology of asphalt mixture and conveying device, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problem of difficult to convey asphalt mixture, and achieve the effect of continuous conveying, improving work efficiency, and simple and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

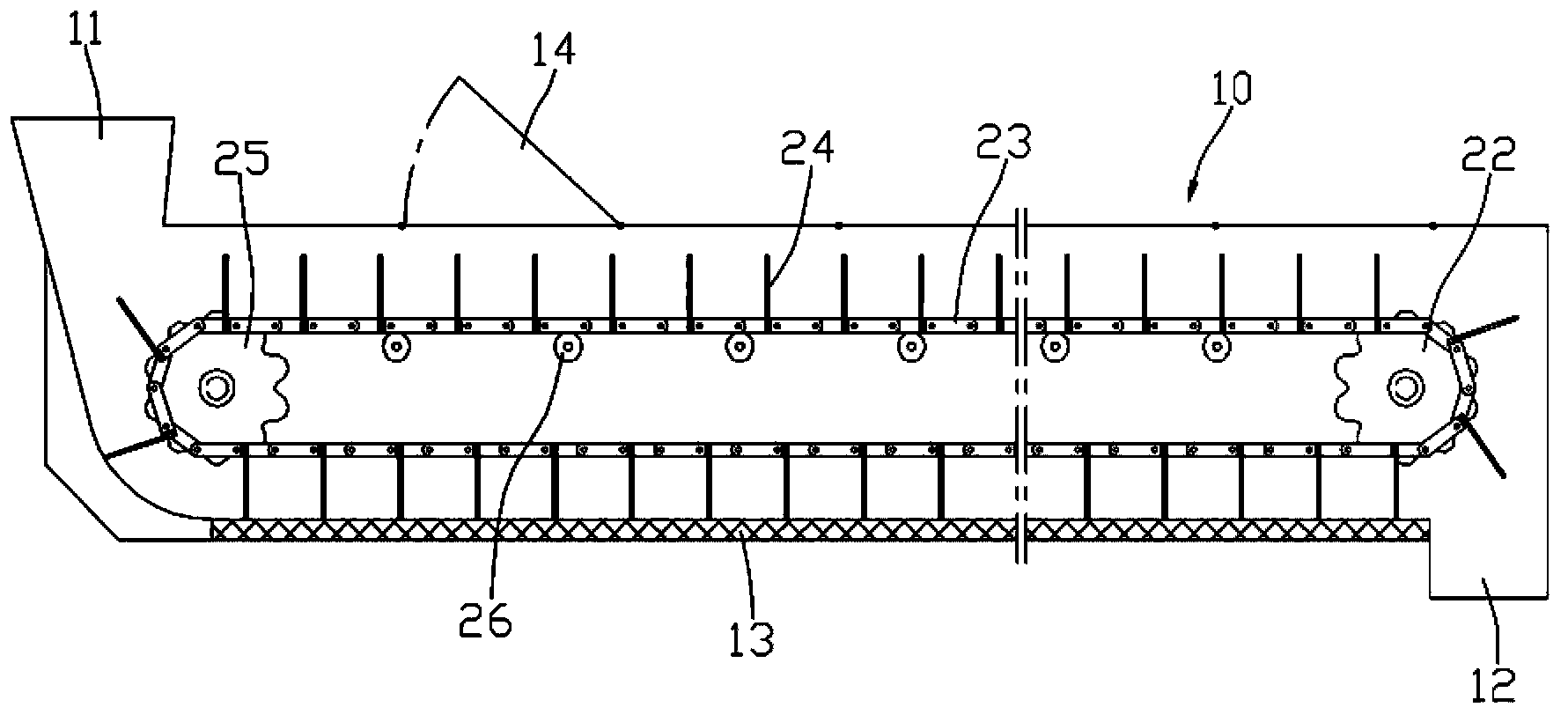

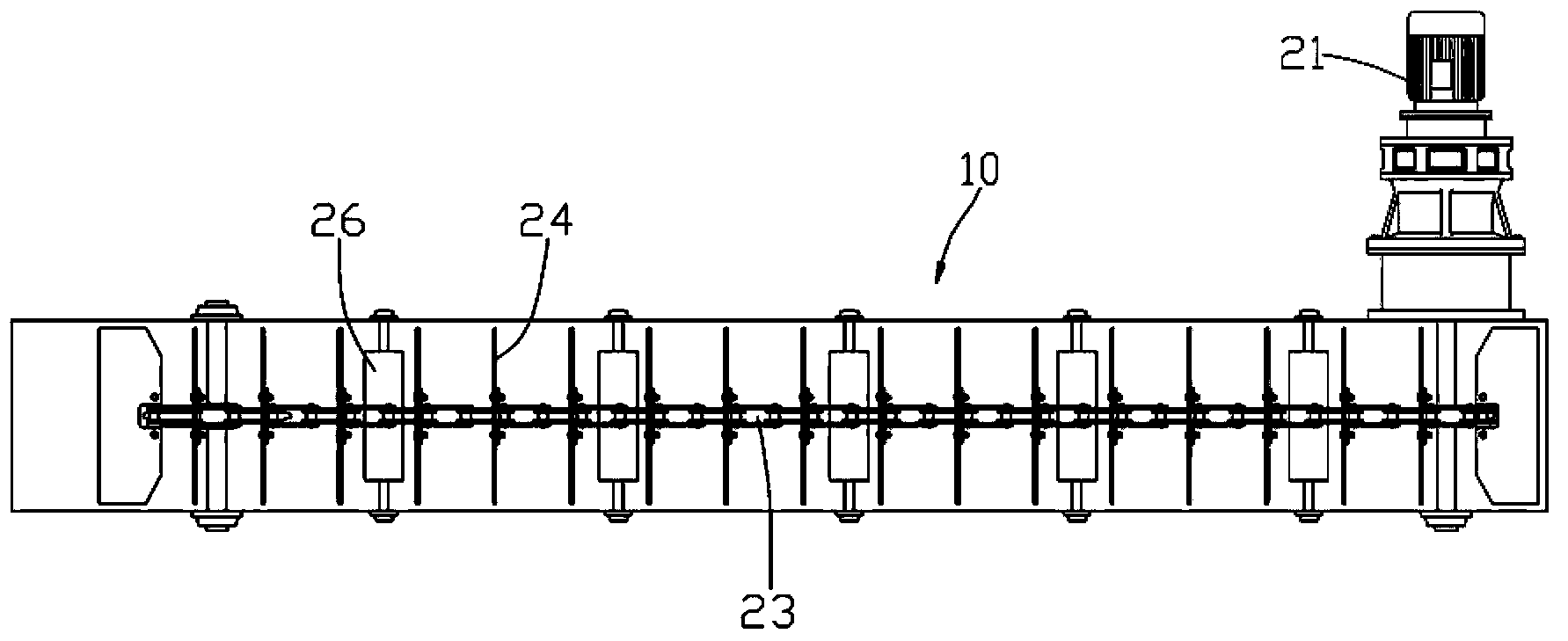

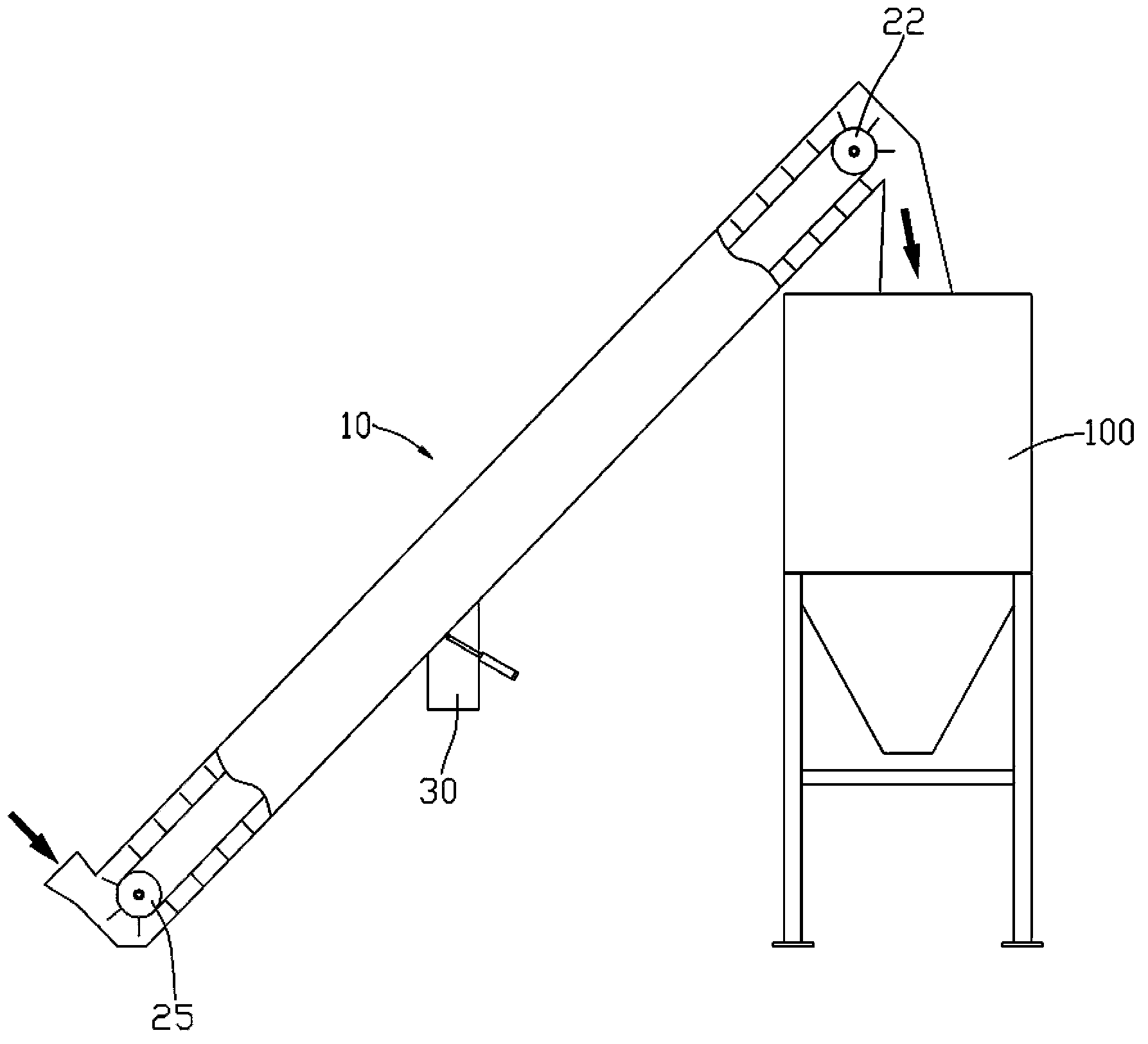

[0020] See Figure 1 to Figure 3 Shown: the asphalt mixture continuous conveying device of the present invention comprises a box body 10, and box body 10 two ends are respectively provided with feed inlet 11, discharge outlet 12, wherein, feed inlet 11 and the discharge of asphalt mixture mixer The discharge port 12 is connected with the asphalt mixture storage silo 100; two coaxial drive sprockets 22 driven by a reducer 21 are arranged at one end of the discharge port 12 in the box body 10, and two drive sprockets 21 Drive two conveying chains 23 synchronously, and the conveying chain 23 is provided with a plurality of scrapers 24 made of wear-resistant material at intervals, and the scrapers 24 are fixed on the conveying chains 23 by bolts for easy replacement. One end of the feeding port 11 is provided with two driven sprockets 25 for adjusting the tension of the conveying chain 23 in the casing 10; the middle part of the conveying chain 23 is provided with a plurality of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com