Method and device for adhering film on screen by shearing protective film in staggered mode

A technology of protective film and screen, applied in packaging and other directions, can solve the problem of difficult to guarantee the quality of pasting, and achieve the effect of saving time and labor, simple operation and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with the accompanying drawings of the device of the present invention, the method of the present invention is described in detail:

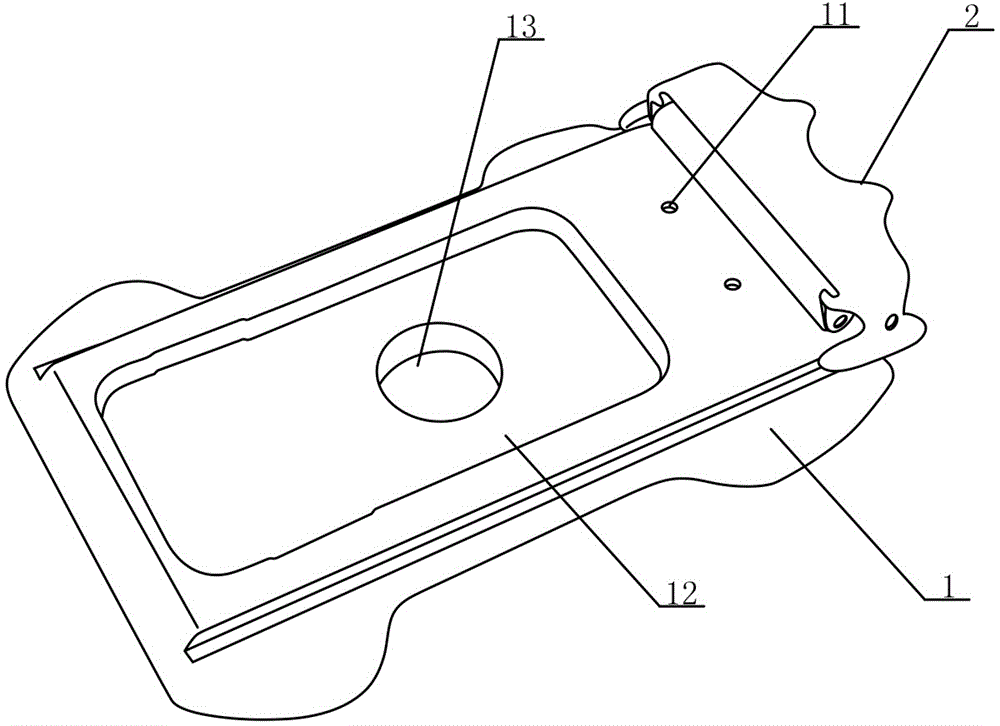

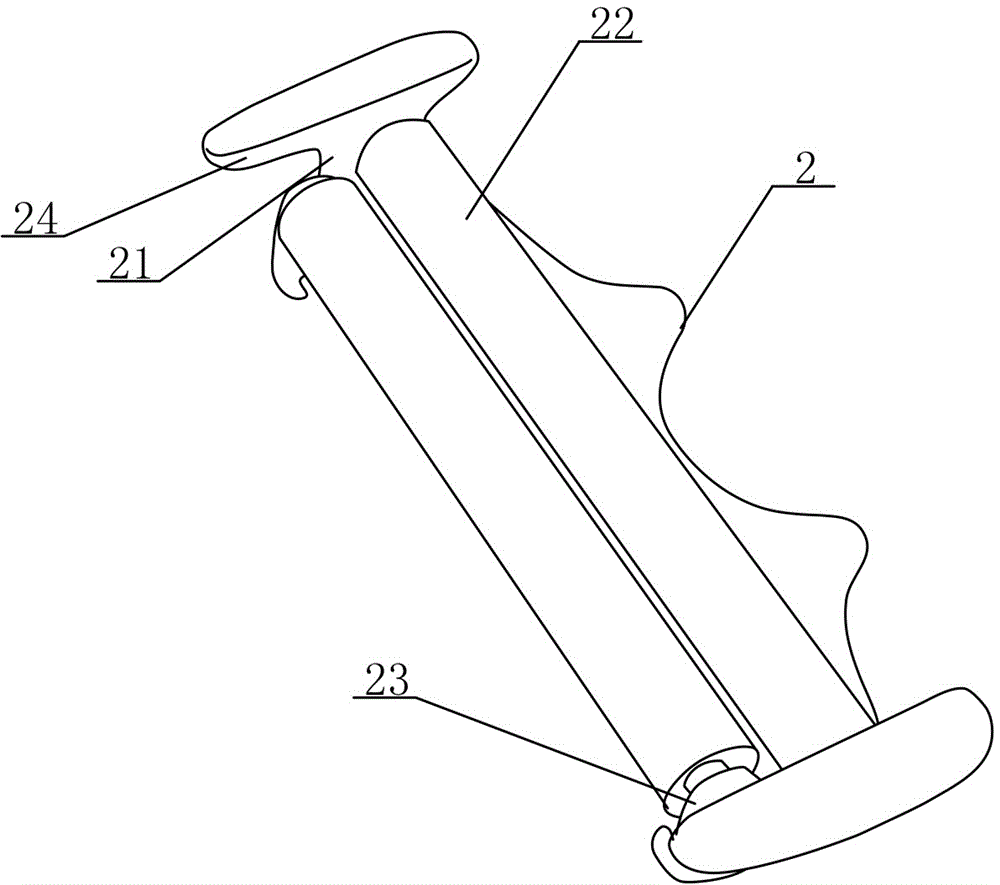

[0033] refer to Figure 1-3 , the device of the present invention comprises:

[0034] A base 1, the front of which is a rectangular parallelepiped with a height of 4-8mm; one end is provided with two positioning holes 11; one side of the positioning hole 11 is opened with an equipment positioning cavity 12 with the same shape as the film sticking equipment; the long side of the rectangular parallelepiped is vertical to the base The seat 1 becomes the slide rail of the roller seat 2; the bottom of the equipment positioning chamber 12 has a round hole 13 penetrating the base 1.

[0035] A roller seat 2 is composed of a roller housing 21 and a roller 22. The roller housing 21 is provided with a roller shaft seat 23, the side wall of the roller housing 21 is provided with a slide rail 24, and the roller 22 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com