Multifunctional automatic welding machine

A multi-functional welding machine technology, applied to the characteristics of welding rods, welding equipment, arc welding equipment, etc., can solve the problems of welding quality, work efficiency, personnel safety, insufficient energy conservation and environmental protection, difficulty for robots to enter small and medium-sized enterprises, and high price, etc., to achieve It is convenient to change the processing program, the welding application range is wide, and the equipment cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

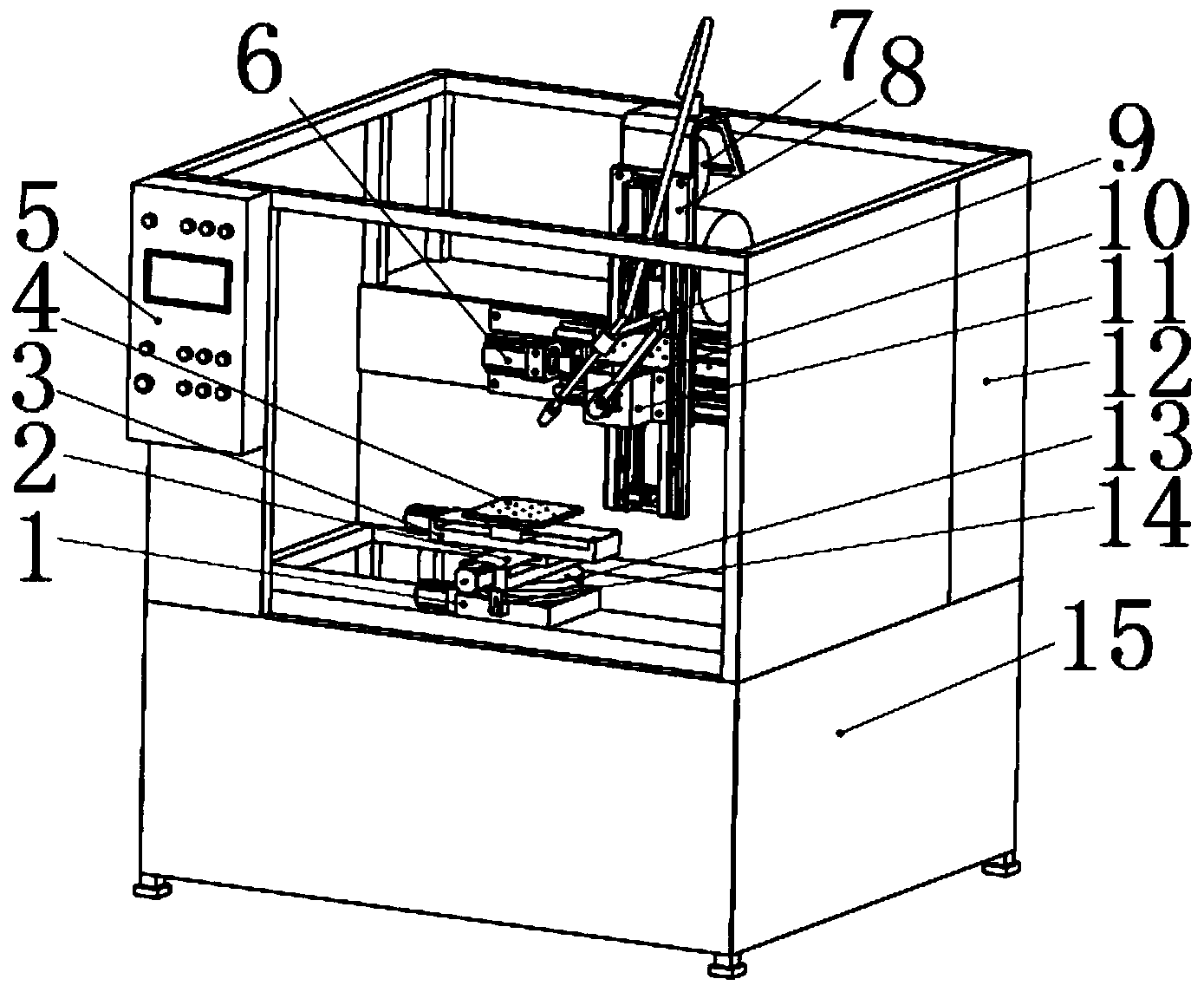

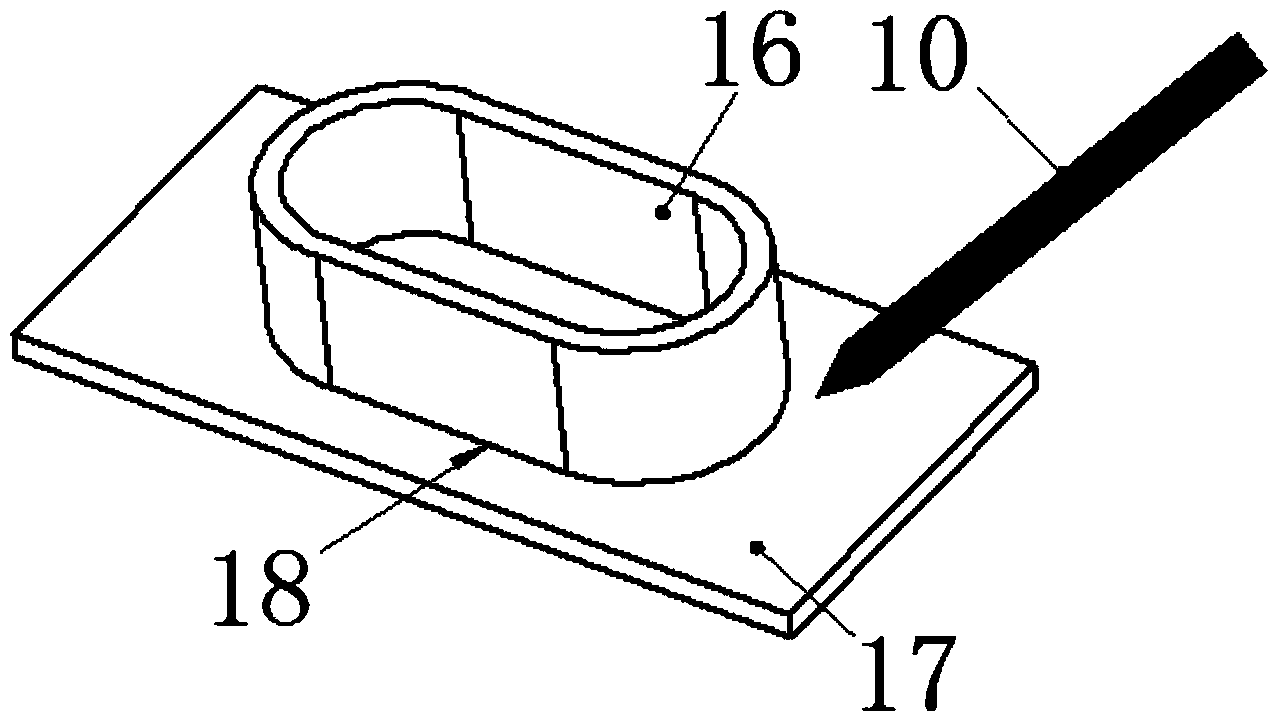

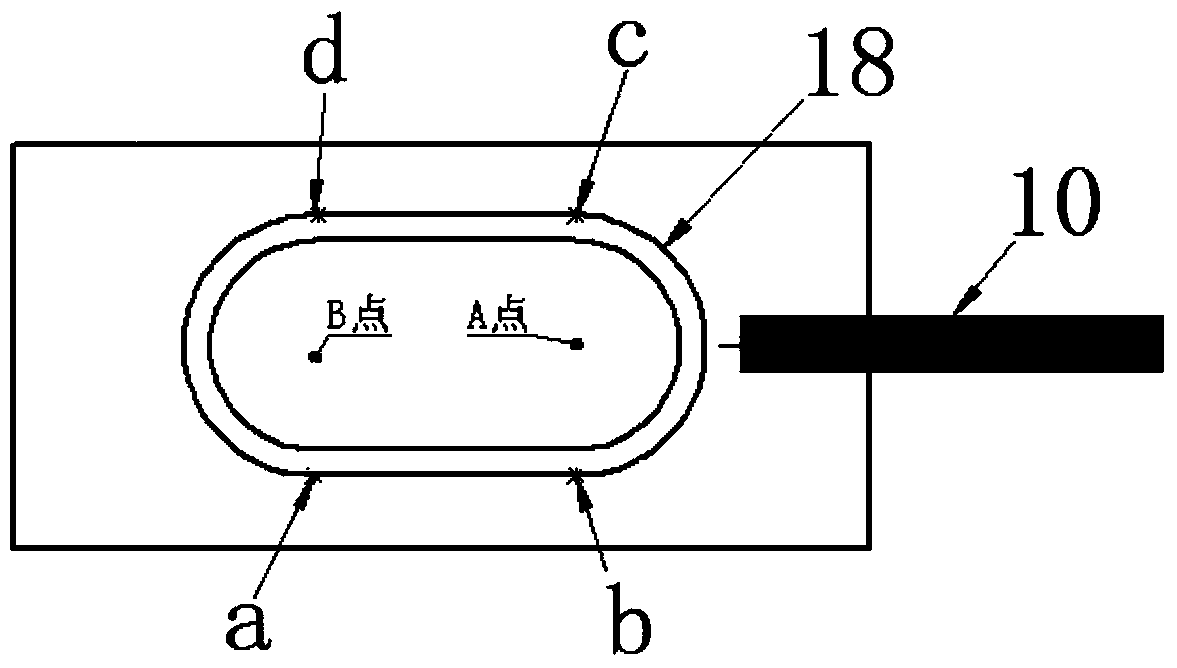

[0022] Such as figure 1 As shown, the multi-functional automatic welding machine includes the welding machine frame and welding torch, as well as the C-axis rotary body 1, the Y-axis sliding table 2, the X-axis sliding table 3, and the C-axis The rotary body 1 is set on the horizontal plane of the horizontal frame of the frame 15, the Y-axis slide table 2 is set above the C-axis rotary body 1, the X-axis slide table 3 is set above the Y-axis slide table 2, and the X-axis slide table 3 is set There is a workbench 4 for fixing welding workpieces, the Y-axis slide table 2 and the X-axis slide table 3 are cross-intersected, and the center point of the C-axis rotary body 1 is point O.

[0023] The automatic welding also includes an R-axis slide table 6, a Z-axis slide table 8, and a B-axis rotary b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com