General release source device for building ventilation and smoke exhaust experiment

A source device and experimental technology, applied in the field of general release source devices, can solve the problems that the momentum released by the medium is not zero, and the high space of the fire source characteristics is not considered, so as to reduce the medium flow rate, improve the similarity, and increase the fluid turbulence. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

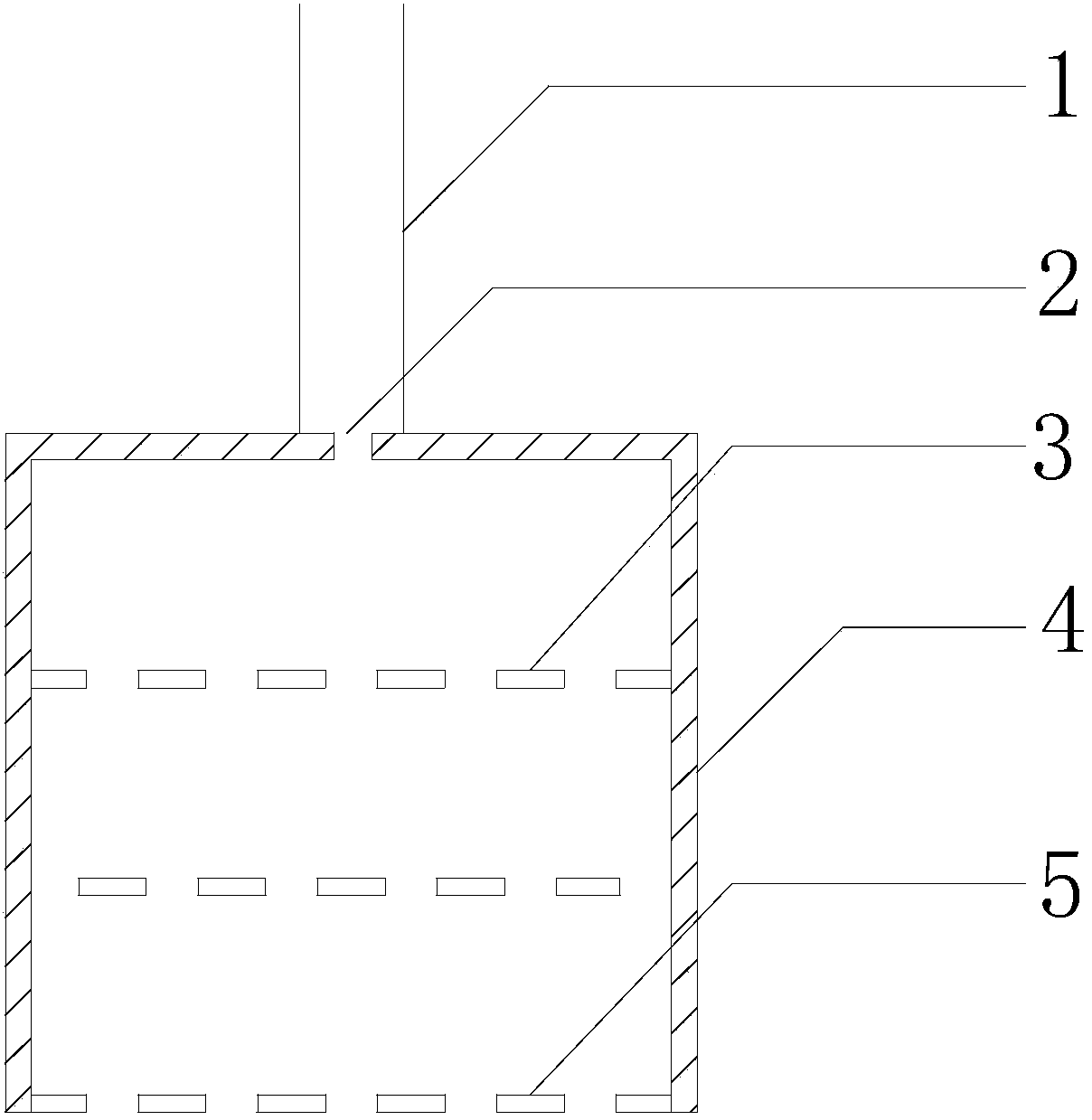

[0030] A general-purpose release source device for building ventilation and smoke exhaust experiments, such as figure 1 As shown, the device includes a medium injection pipe 1 and a buffer chamber 4. The buffer chamber 4 is connected to the lower end of the medium injection pipe 1. A medium injection hole 2 is opened on the wall of the connection between the buffer chamber 4 and the medium injection pipe 1. The buffer chamber 4 is provided with an internal guide orifice 3 , and the bottom of the buffer chamber 4 is provided with an outlet guide orifice 5 .

[0031] Wherein, the medium injection pipe 1 is a cylindrical pipe, and the medium injection pipe 1 and the buffer chamber 4 are connected by welding. The buffer cavity 4 is a cylindrical cavity. There may be several internal guide orifice plates 3, which are vertically layered inside the buffer chamber 4. In this embodiment, there are two internal guide orifice plates 3, which are divided into upper and lower layers and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com