A digital quality inspection method for large panel parts

A quality inspection method and technology for large-scale wall panels, which are applied to measurement devices, instruments, optical devices, etc., can solve the problems of incomplete data collection and low detection efficiency, and achieve the effects of strong operability, simple method, and improved alignment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

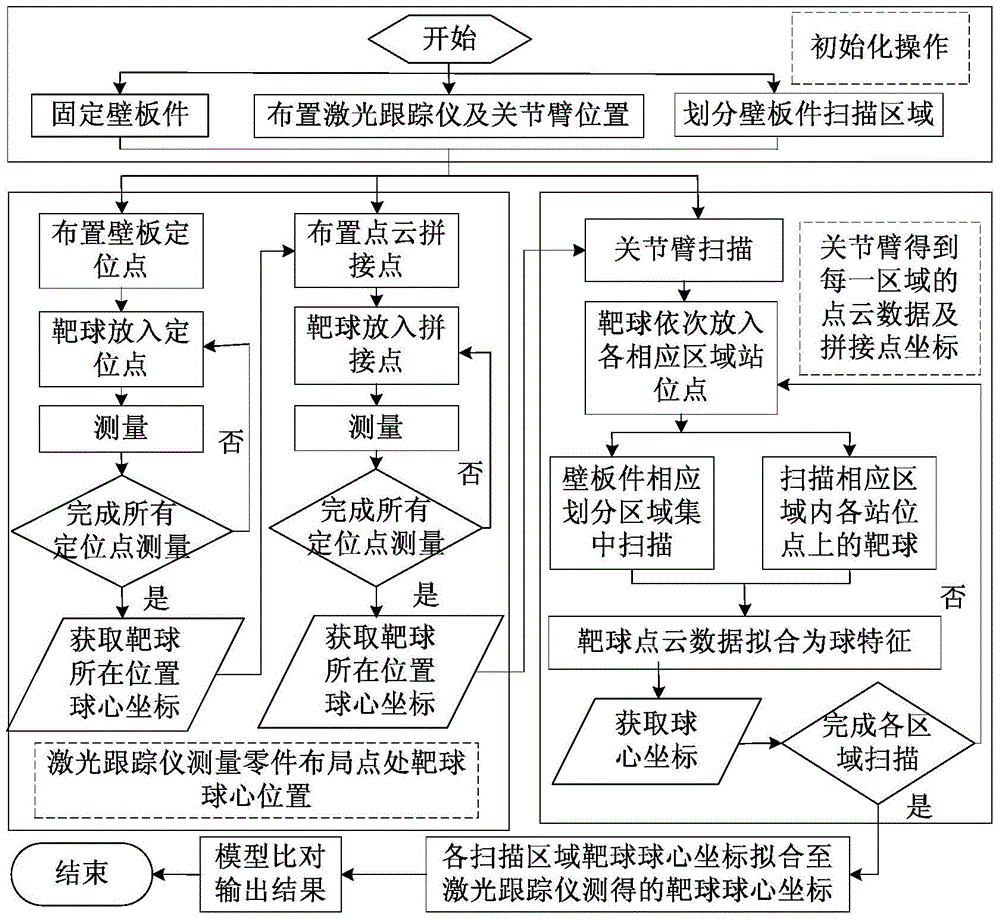

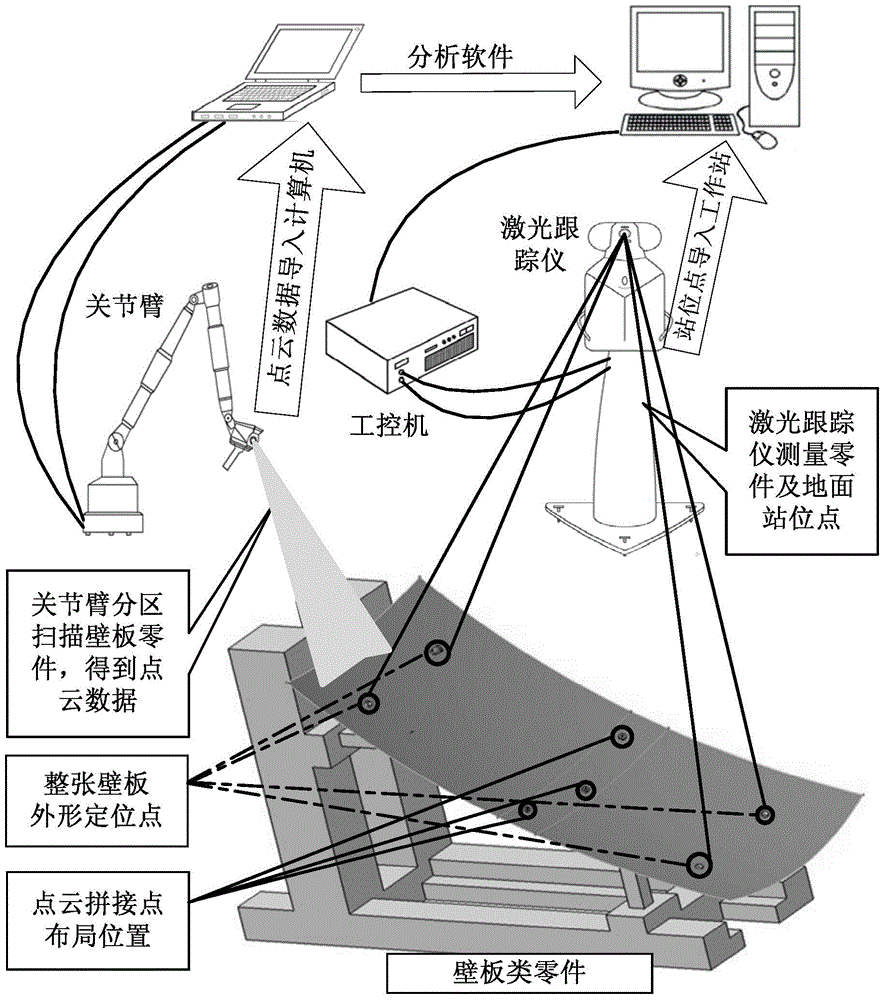

[0060] The present invention is a digital quality inspection method for large-scale wallboard parts, and the steps of the method are shown in figure 1 , see the measurement process figure 2 , the specific steps are as follows:

[0061] Step 1: Initialize the operation before measurement, including: fixing the wallboard parts to be tested, dividing the scanning area of the wallboard parts to be tested, and arranging the position of the laser tracker and the joint arm.

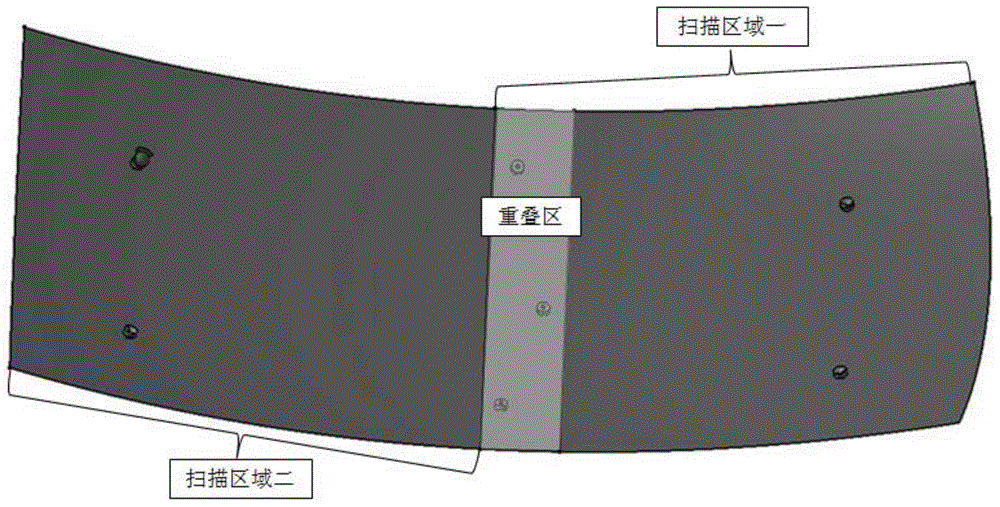

[0062] The position of the laser tracker is fixed during the measurement. When dividing the scanning area of wallboard parts, it should be noted that there must be a common overlapping area between different areas. This overlapping area will be used to arrange the splicing points. Select a wall panel with a length of 2.8m and a width of 0.8m as the detection object. The scanning range of the articulated arm is a spherical measurement space with a radius of 2.5m, so it is only necessary to divide the wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com