A new type of double-convex disc structure for collective doffing of ring spinning frame

A spinning frame and convex disc technology, applied in textile and paper making, etc., can solve the problems of large movement range of collective doffing air frame, long action execution time, unstable execution action, etc., to simplify the mechanical action and reduce the mechanical movement. , perform action stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

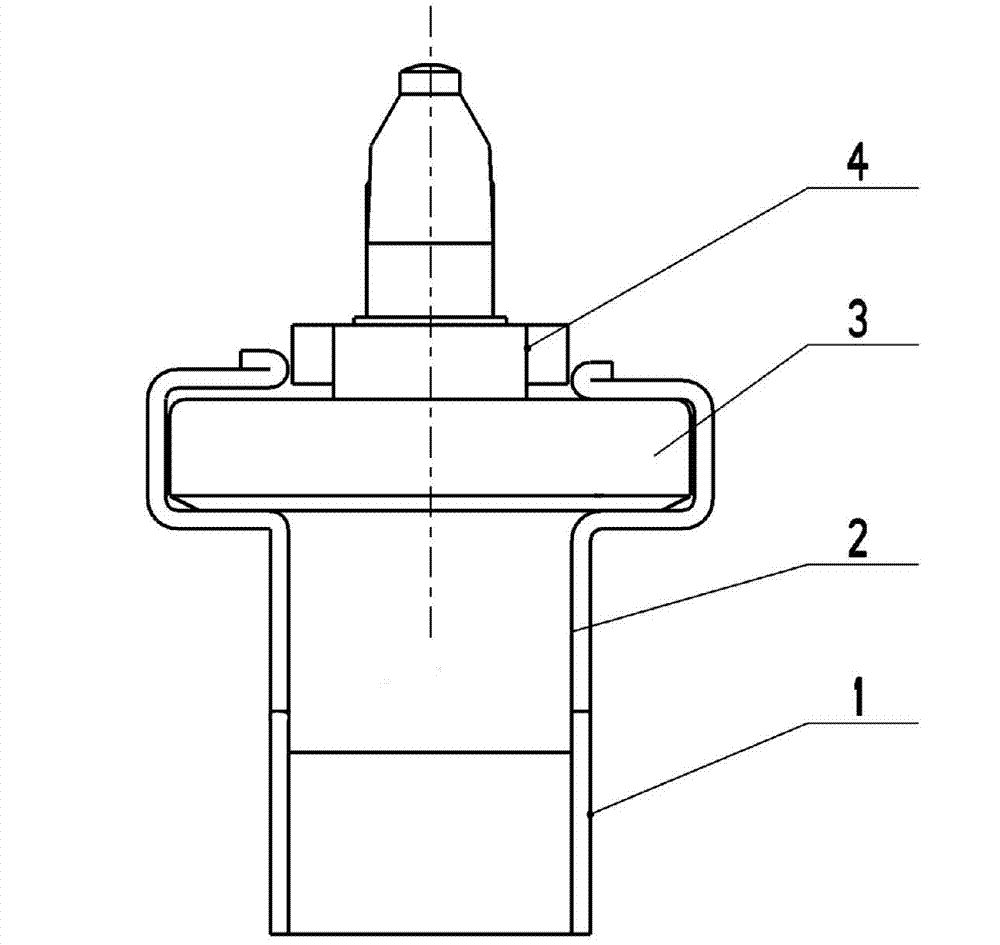

[0015] Example: such as figure 1 As shown in the figure, a new type double convex disk structure for collective doffing of ring spinning frame, including the convex disk inner guide rail 1, the convex disk outer guide rail 2, the main convex disk 3 and the auxiliary convex disk 4, the convex disk inner guide rail 1 and the convex disk outer guide rail The guide rail 2 maintains a fixed distance to form a guide channel for the operation of the main cam and the auxiliary cam, and the bottom of the guide channel is connected with the lower bracket of the wallboard in the ring spinning frame to play a guiding role.

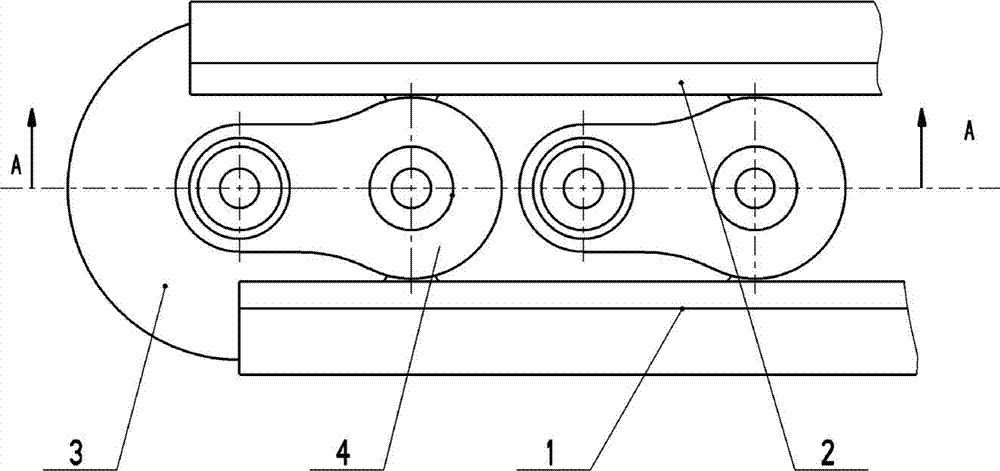

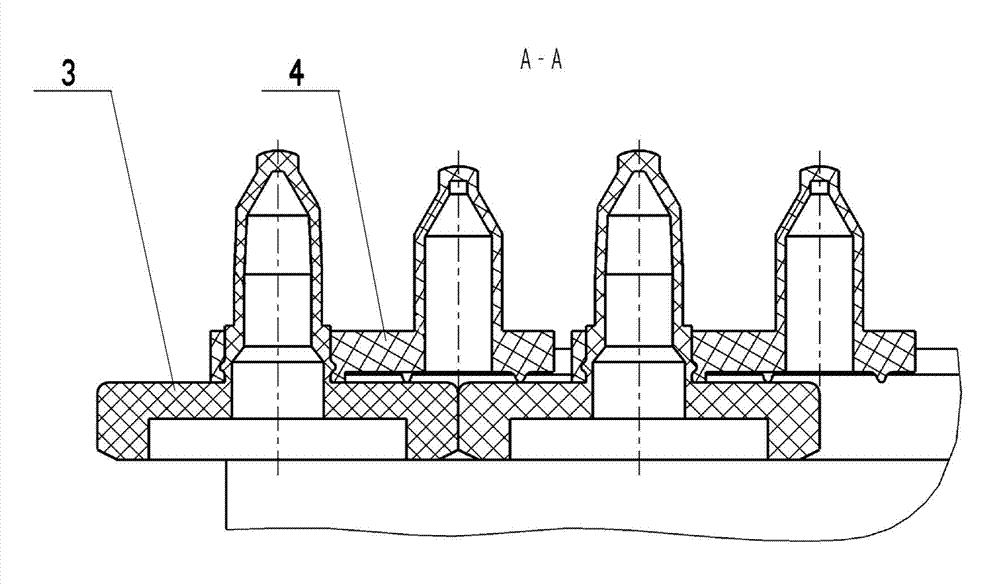

[0016] like figure 2 , 3 As shown, the main convex plate 3 and the auxiliary convex plate 4 are connected in pairs, and are arranged in the guide channel in sequence. At the same time, the protruding cylinder on the main convex plate 3 and the positioning hole on the auxiliary convex plate 4 are connected by snap fit, which is convenient Installation and disassembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com