Supporting frame, forming assembly device of supporting frame and boxing method of supporting frame

A technology for assembling devices and supporting frames, which is applied in the directions of packaging, transportation and packaging, rigid containers, etc., and can solve the problems of occupying space and easy breakage of positioning devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

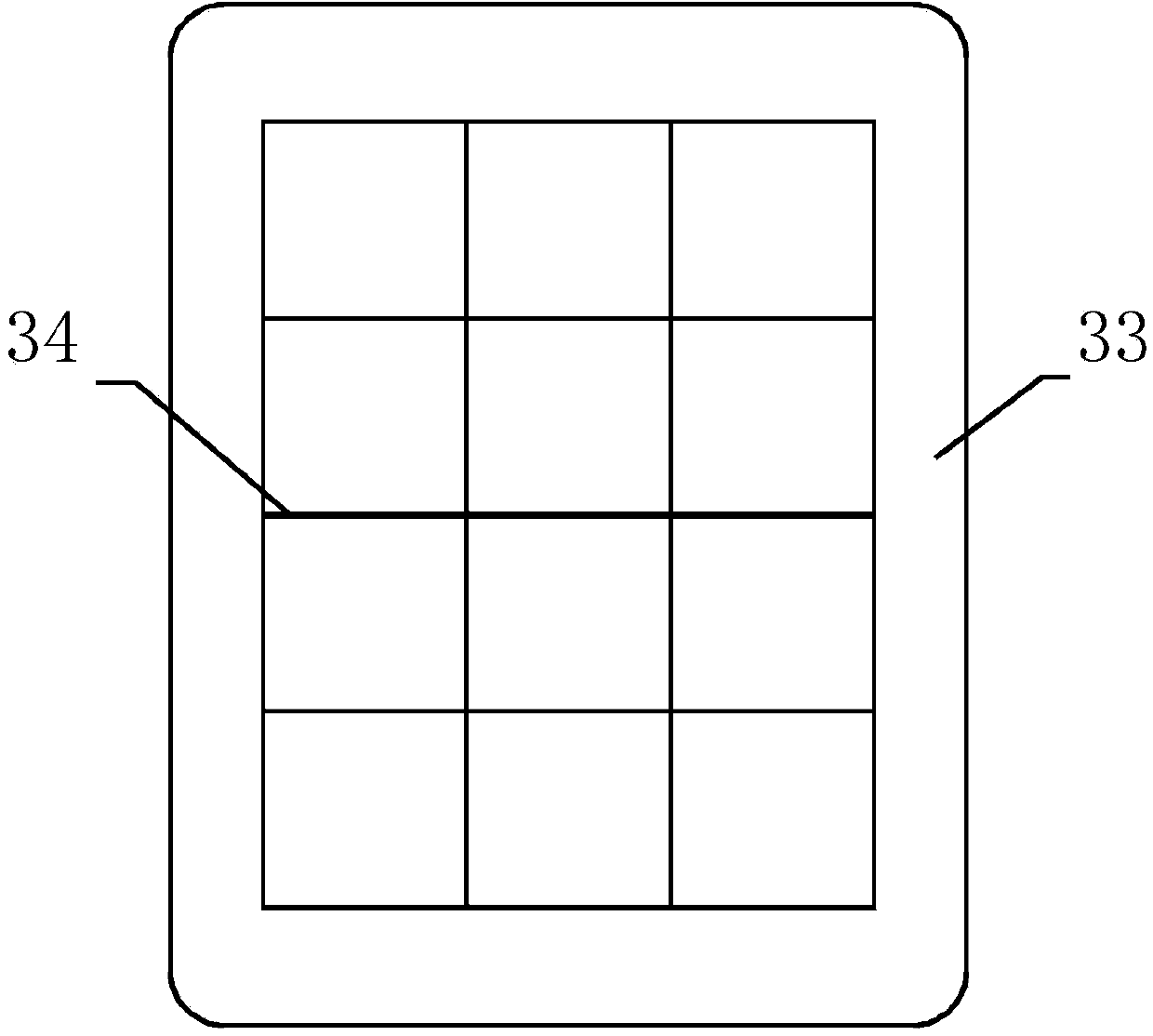

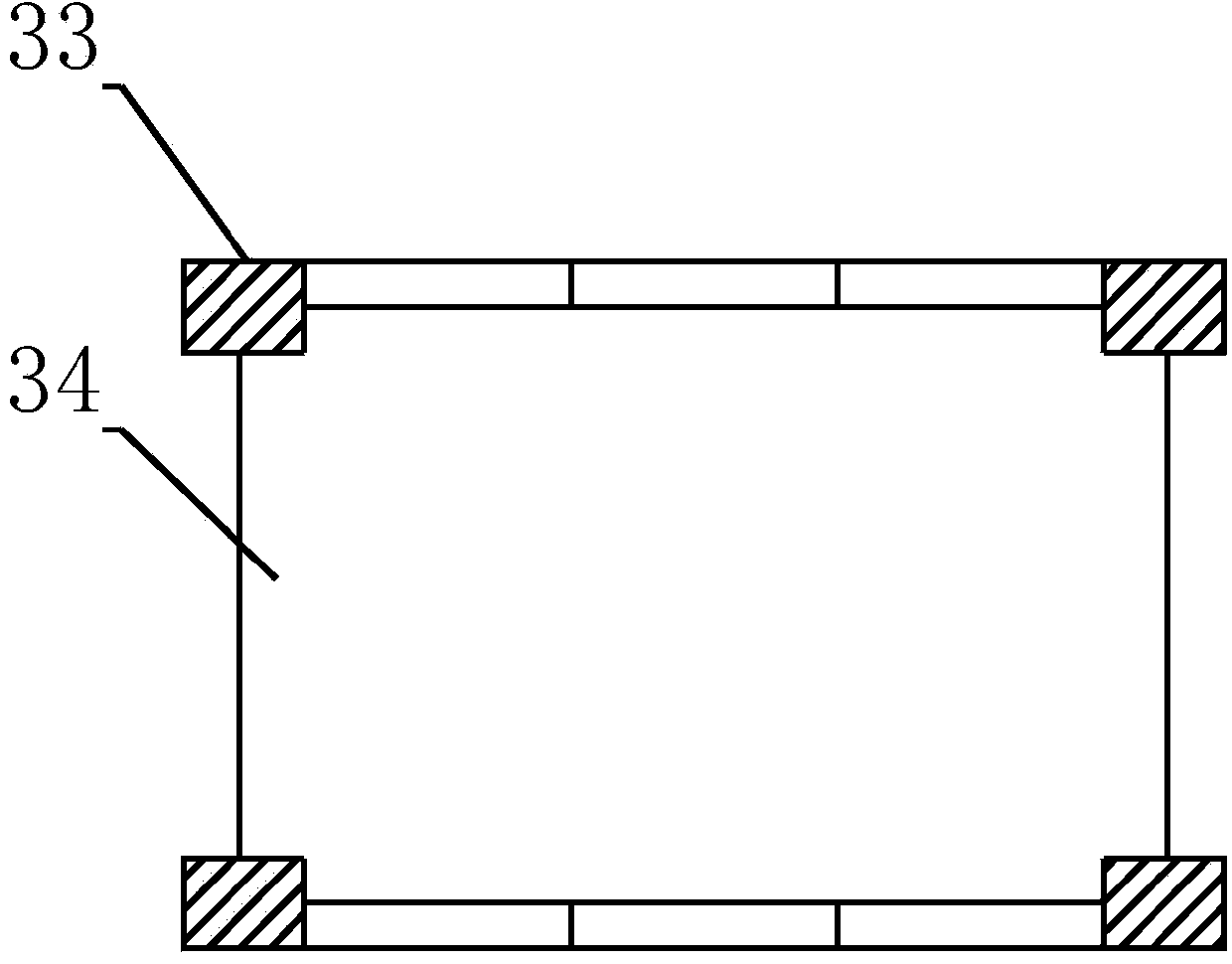

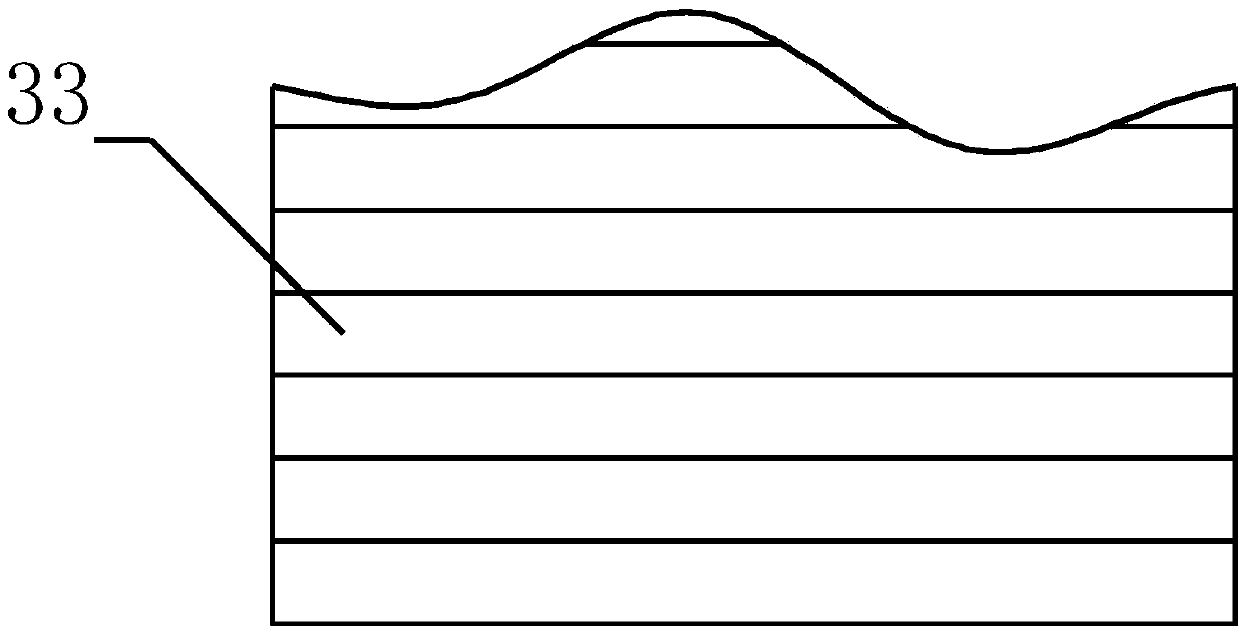

[0057] Such as Figure 4 As shown, the upper support frame is die-cut from corrugated cardboard, and the overall shape is a cross. The corrugated cardboard is formed by bonding face paper and a wavy core paper interlayer, and the wavy core paper interlayer is continuously bent to form grooves 7, and adjacent grooves face opposite directions and extend in parallel. After die-cutting and forming, the upper support frame body is provided with a positioning part 2, a wrapping part 3, and a supporting part 4. The wrapping part 3 and the supporting part 4 are connected as a whole and are all in the same plane. The wrapping part 3 and the positioning part 2 are demarcated and distinguished by the crease line 5, and the support part 4 and the positioning part 2 are demarcated and distinguished by the crease line 5. A crease line is provided on the wrapping part 3, so that the wrapping part is divided into a transverse wrapping part and a longitudinal wrapping part, one side of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com