Shaft end location and locking structure of stirrer

A technology for positioning and locking mixers, applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the vibration of the stirring shaft, affect the operation and service life of the mixer, and cannot effectively ensure the centering and positioning of the stirring shaft, etc. problems, to achieve the effect of overcoming complex structure, improving running stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

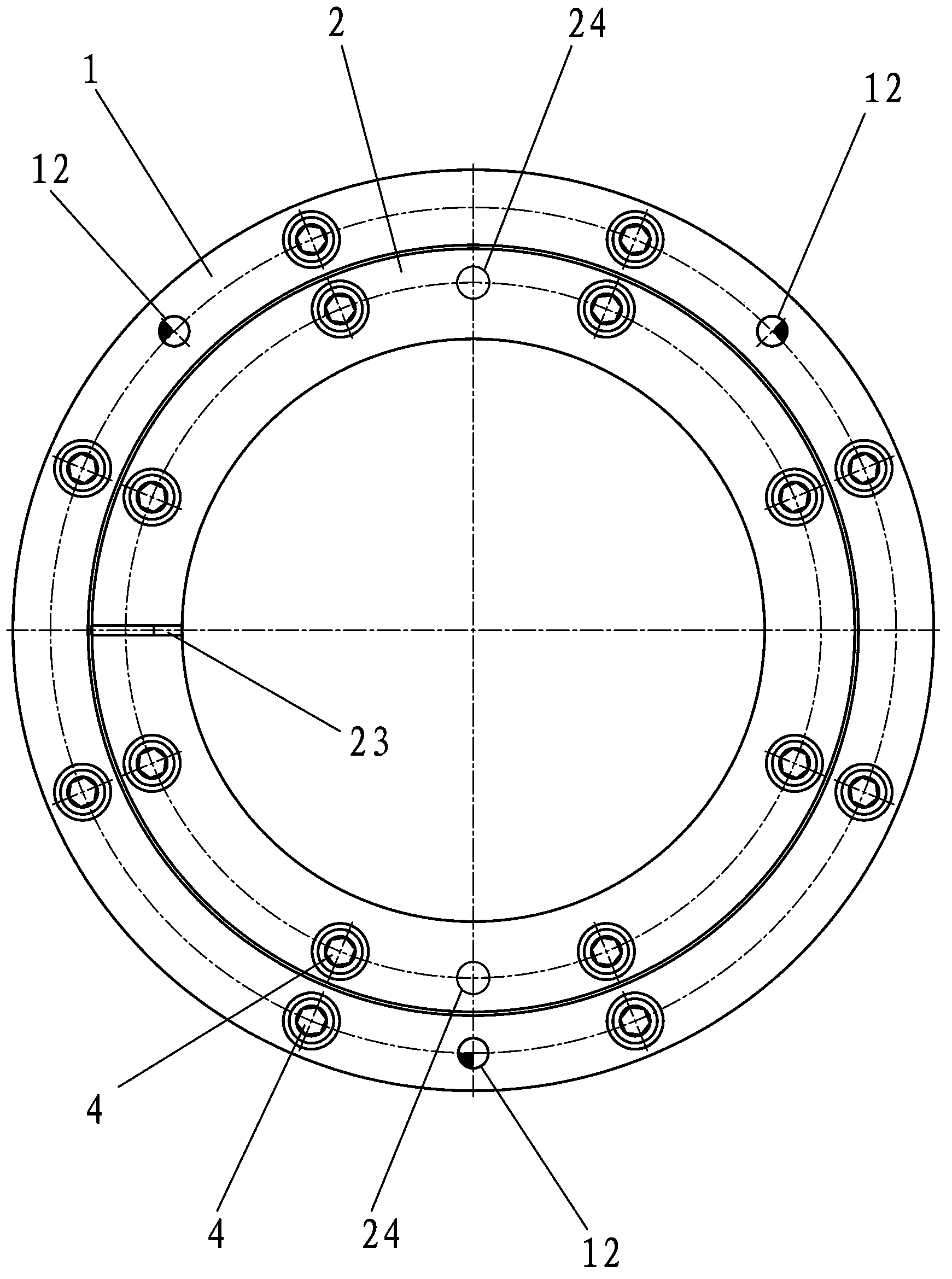

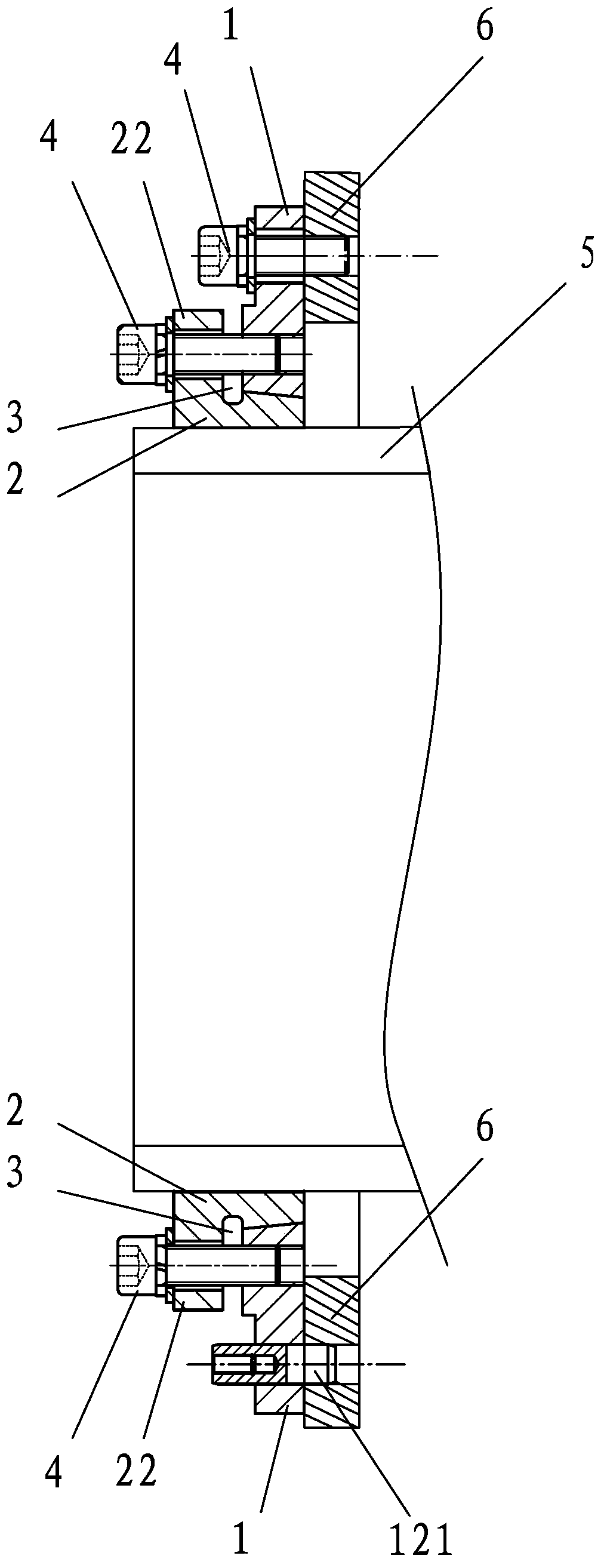

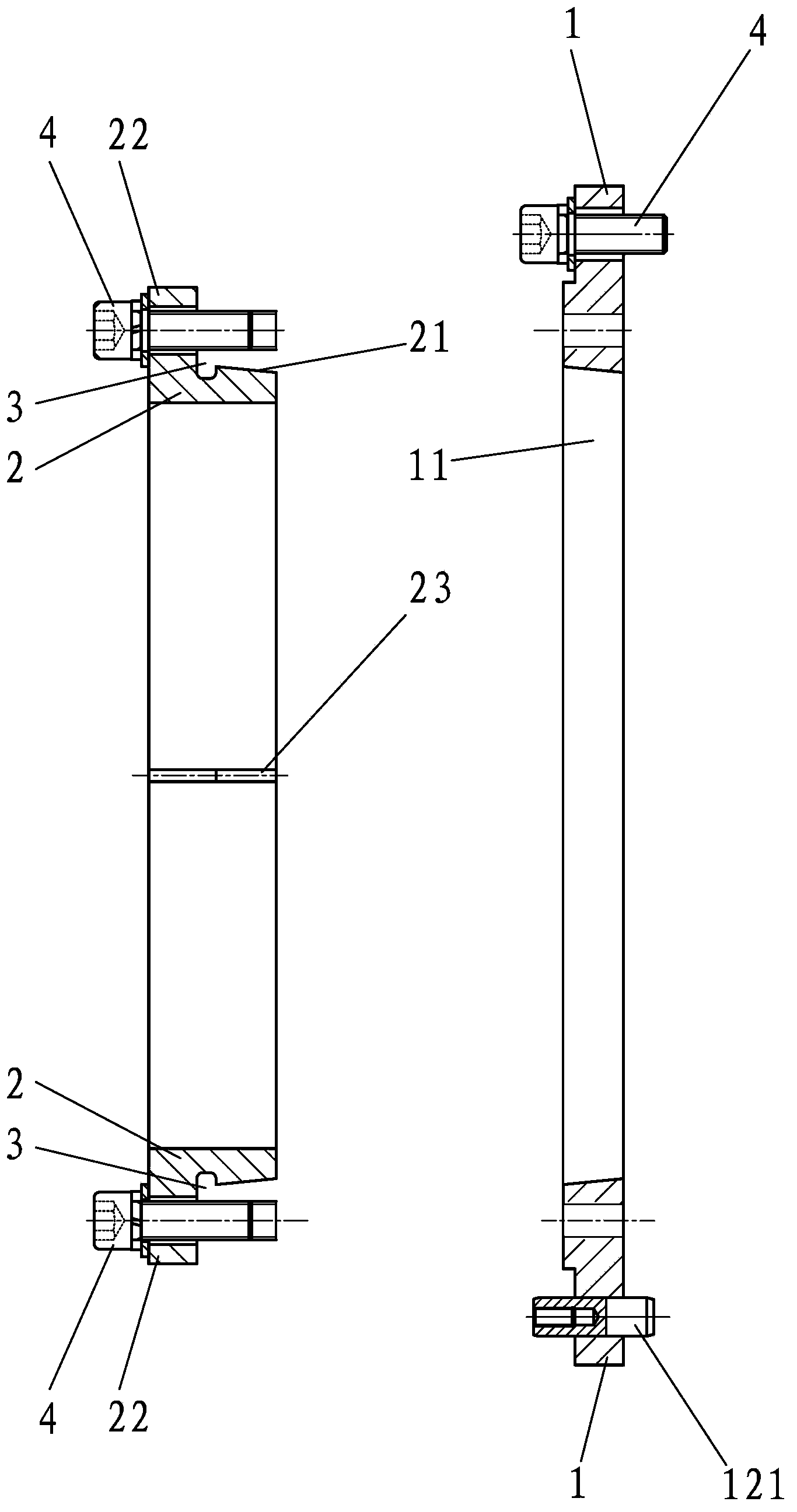

[0027] A shaft end positioning and locking structure of the mixer of the present invention, such as Figure 1-3 As shown, it includes positioning taper sleeve 1 and locking inner cone 2.

[0028] The positioning cone sleeve 1 is fixed with the end wall of the mixer, the locking inner cone 2 is installed with the shaft end bearing seat 5 of the mixer, and the locking inner cone 2 is locked together with the positioning cone sleeve 1; the positioning cone sleeve 1 is formed by Conical bushing 11 tapering from outside to inside, locking the inner cone 2 to form a conical bushing 21 matched with the conical bushing 11 from outside to inside, during use, the positioning cone bushing 1 is fixed on the end wall of the mixer Above, the conical sleeve head 21 of the locking inner cone 2 is matched and installed in the conical sleeve hole 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com