Testing method for verifying reliability of tee joint welding process

A technology of welding process and verification test, which is applied in the field of reliability verification test of three-way welding process, can solve the problems of unqualified process evaluation, waste of funds, large time and energy consumption, etc., so as to save evaluation time, improve production efficiency, reduce The effect of trial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

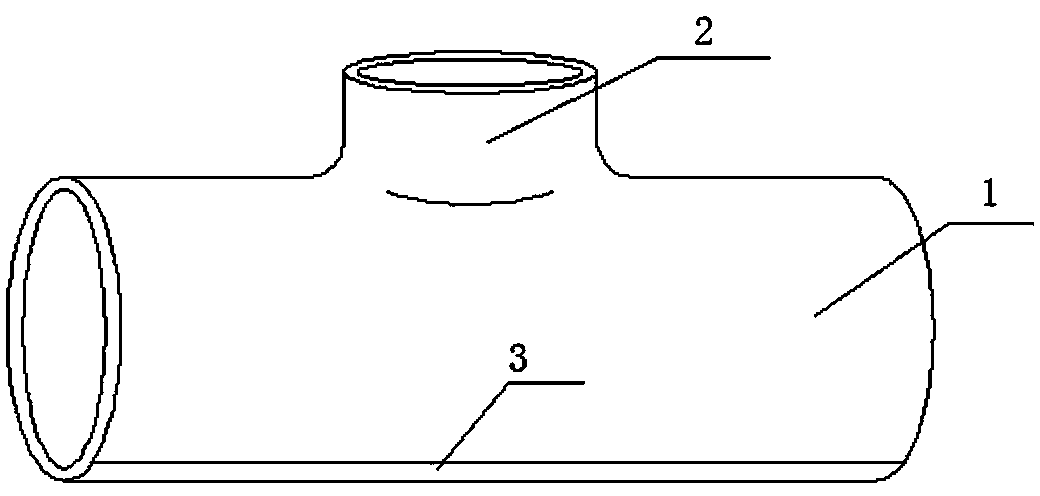

[0029] Such as figure 1 -to Figure 4 A method for verifying the reliability of a three-way welding process includes the following steps: step 1, welding a blank pipe for tee manufacture, and then forming a blank welding seam on the blank pipe;

[0030] Step 2, processing no less than two groups of welding grooves on the blank tube by arc gouging;

[0031] Step 3, then use a welding process different from that in step 1 to weld each group of the test welding grooves to form a test weld; and each group of the test welding grooves also use different welding processes to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com