Method for cleaning condenser of turbine closed-type circulating water system

A closed cycle, steam turbine technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as increased back pressure, unsatisfactory state, adverse effects of back pressure and unit energy consumption, etc., to achieve easy flow, The effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the present embodiment, the cleaning method for the steam turbine condenser of the closed circulating water system is:

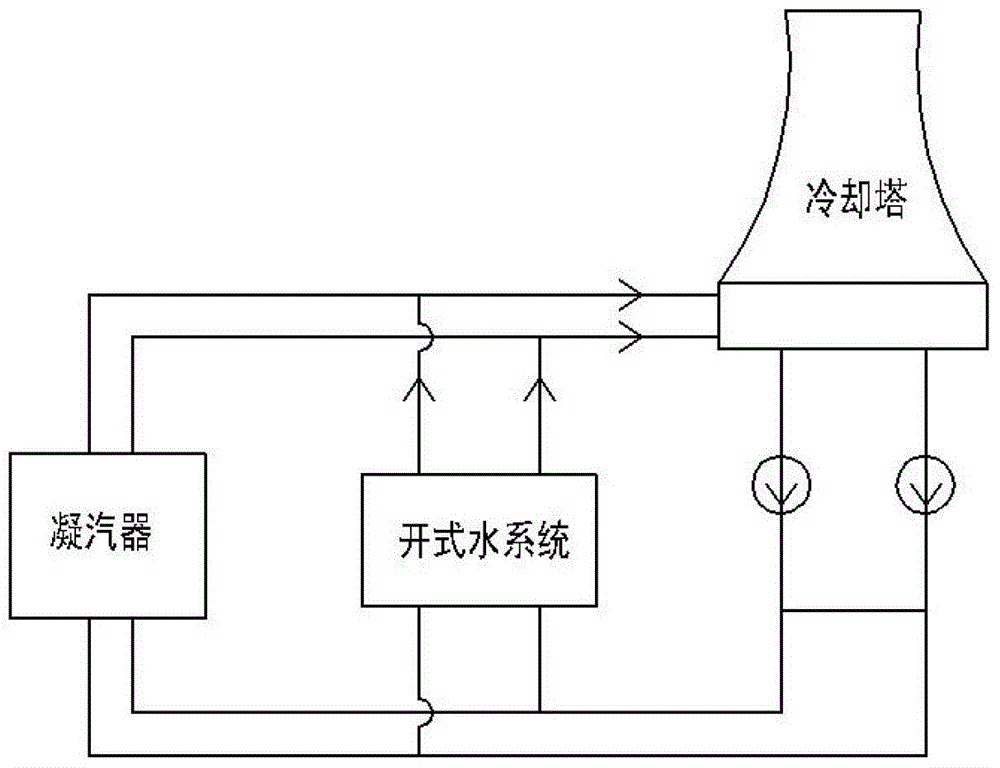

[0025] Such as figure 1 As shown, in the steam turbine closed circulating water system including cooling tower, condenser and open water system, the cleaning effect of sand on the tube bundle in the open circulating water system of the steam turbine is simulated, and the circulation of the closed circulating water system of the steam turbine is Solid particles are added to the water to form circulating water containing solid particles to achieve continuous cleaning of the condenser in the closed circulating water system of the steam turbine and the coolers in the open water system; the solid particles are ceramsite sand.

[0026] In the specific implementation, the circulating water containing solid particles is to add solid particles in the circulating water of the closed circulating water system of the steam turbine at a ratio of 100-400 ppm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com