Liquid feed for live pigs and preparation process thereof

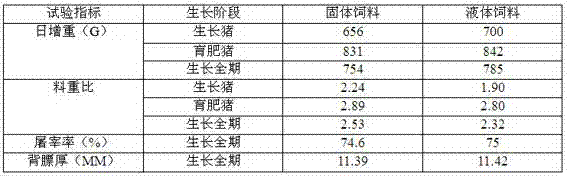

A technology of liquid feed for live pigs and a preparation process is applied in the field of liquid feed for live pigs and the preparation process thereof, which can solve the problems that the solid feed of live pigs cannot meet the feeding requirements, and achieve the effects of realizing green and environmental protection breeding, increasing productivity and improving morphological structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The invention is a liquid feed, which is mainly used for feeding pigs and can meet the feeding requirements of each stage of refined breeding. Specifically, the liquid feed is prepared from the following raw materials:

[0057] Corn: 2.85% to 8.55%;

[0058] Barley: 2.85% to 8.55%;

[0059] Soybean meal: 2.15%~6.45%;

[0060] Fish meal: 4% to 12%;

[0061] Skimmed milk powder: 8% to 16%;

[0062] Whey powder: 7.85% to 23.55%;

[0063] Fat powder: 3% to 9%;

[0064] Concentrate: 1.65%~4.95%;

[0065] Water: 19.65% to 58.95%.

[0066] Among them, the concentrated material is composed of the following proportioning raw materials:

[0067] Fried bean powder: 20% to 60%;

[0068] Bone meal: 5% to 15%;

[0069] Loach powder: 5% to 15%;

[0070] Sunflower powder: 13.3% to 39.9%;

[0071] Light calcium carbonate: 2% to 6%;

[0072] Salt: 2.5% to 7.5%;

[0073] Lysine: 0.75%~2.25%;

[0074] Methionine: 0.25%~0.75%;

[0075] Enzyme preparation: 0.1%~0.3%;

[0076...

Embodiment 2

[0109] The difference from Example 1 is that in this example, the ratios of corn, barley, soybean meal, water, fish meal, skimmed milk powder, whey powder, fat powder, and concentrate are: corn 5.7%, barley 5.7% %, soybean meal 4.3%, water 39.3%, fish meal 8%, skimmed milk powder 12%, whey powder 15.7%, fat powder 6%, concentrated material 3.3%; In the described concentrated material, the proportioning of various substances is respectively: Fried soybean powder 40%, bone meal 10%, loach powder 10%, sunflower powder 26.6%, light calcium carbonate 4%, salt 5%, lysine 1.5%, methionine 0.5%, enzyme preparation 0.2%, multidimensional powder 1% , trace elements 1.15%, olaquindox 0.05%. Under this ratio, various substances are prepared with the ratio of intermediate values, which can make the performance of liquid feed reach the best balance.

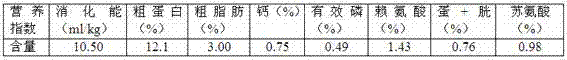

[0110] The liquid feed prepared by the preparation ratio used in this example was also tested for its main nutritional components and conten...

Embodiment 3

[0125] The difference from Example 1 is that in this example, the proportions of corn, barley, soybean meal, water, fish meal, skimmed milk powder, whey powder, fat powder, and concentrate are: corn 8.55%, barley 8.55% %, soybean meal 4.5%, water 53.9%, fish meal 4%, skimmed milk powder 8%, whey powder 7.85%, fat powder 3%, concentrated material 1.65%; In the described concentrated material, the proportioning of various substances is respectively: Fried soybean powder 60%, bone meal 15%, loach powder 5%, sunflower powder 13.3%, light calcium carbonate 2%, salt 2.5%, lysine 0.75%, methionine 0.25%, enzyme preparation 0.1%, multidimensional powder 0.5% , trace elements 0.575%, olaquindox 0.025%. Under this ratio, the proportion of solid raw materials and water is relatively large, which is suitable for feeding pigs with large daily feed intake.

[0126] The liquid feed prepared by the preparation ratio used in this example was also tested for its main nutritional components and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com