fuel dispenser

A technology of fuel distributor and fuel valve, which is applied in the direction of fuel injection device, liquid fuel feeder, charging system, etc. It can solve the problems of mass loss and achieve the effect of compact structure, simple installation and reliable fuel dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

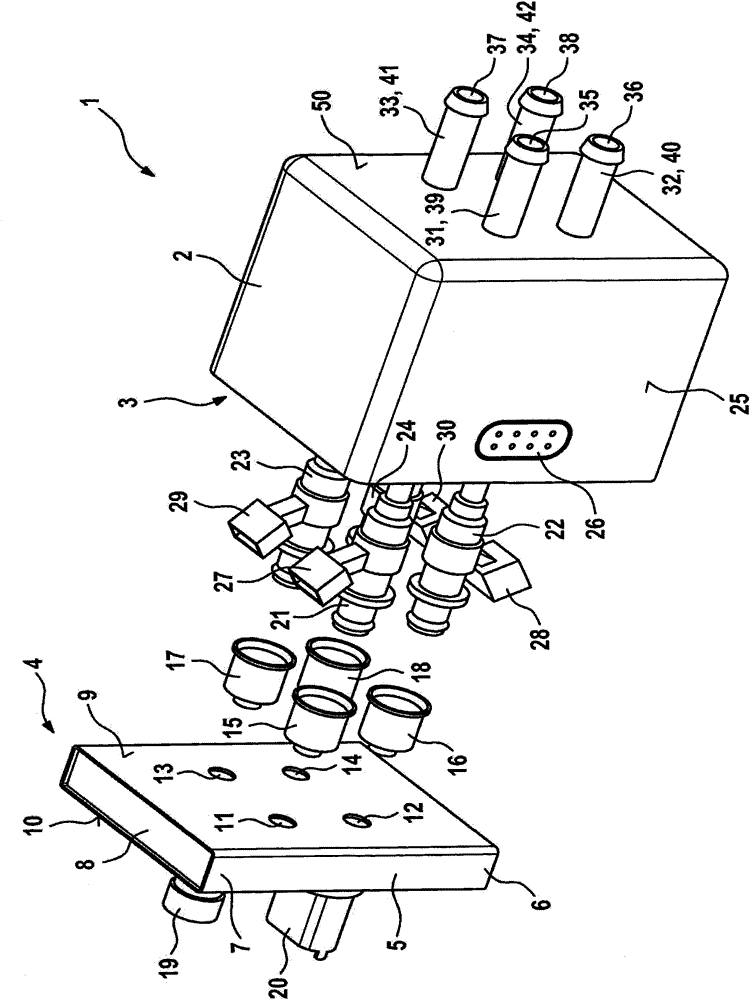

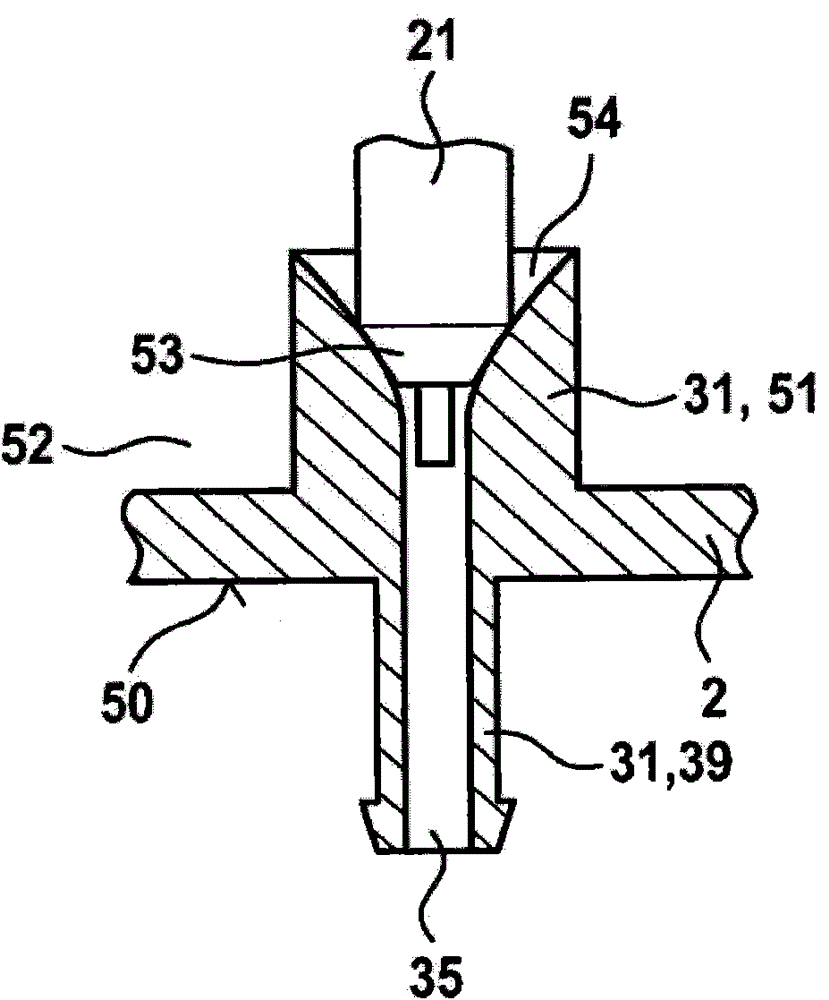

[0015] figure 1 An exemplary embodiment of the fuel distributor 1 is shown in a schematic exploded perspective view. The fuel distributor 1 can be used in particular as an injection block 1 of a fuel injection system for a hybrid compression, externally ignited internal combustion engine. The fuel distributor 1 is particularly suitable here for distributing natural gas to a plurality of cylinder chambers of an internal combustion engine.

[0016] The fuel distributor 1 has a housing 2 with an opening 3 . Furthermore, a fuel distributor block 4 is provided, which closes the opening 3 of the housing 2 in the assembled state. In this case, the fuel distributor block 4 is inserted into the opening 3 of the housing 2 . The fuel distributor block 4 has a tubular base body 5 with a quadrangular outline. The two ends 6, 7 of the tubular base body 5 are closed by a closure piece 8, wherein, in the attached figure 1 The closure tab 8 is shown and labeled in . In this case, the clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com