Method for preparing reverse osmosis membrane, and reverse osmosis membrane prepared thereby

A technology of reverse osmosis membrane and supporting membrane, applied in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of reduced thickness uniformity of active layer, reduced osmotic flow rate efficiency, reduced productivity, etc., and achieve excellent desalination Excellent efficiency, uniformity, and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

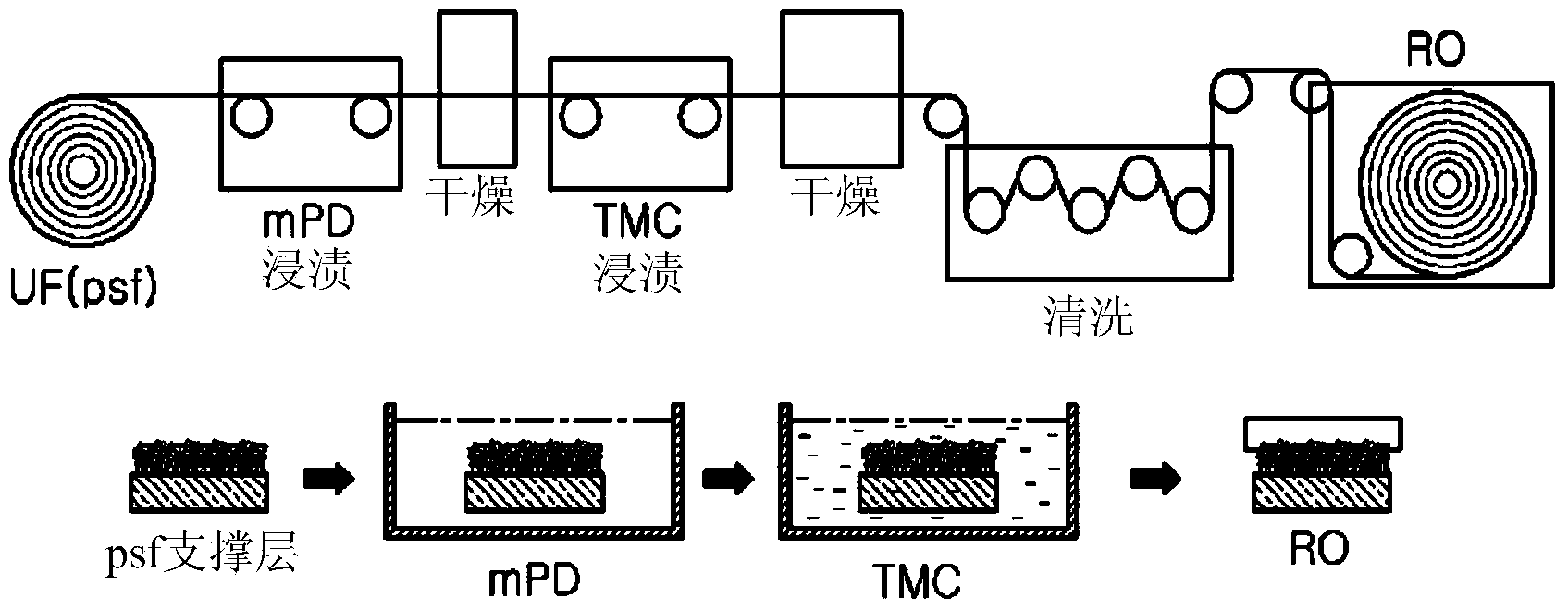

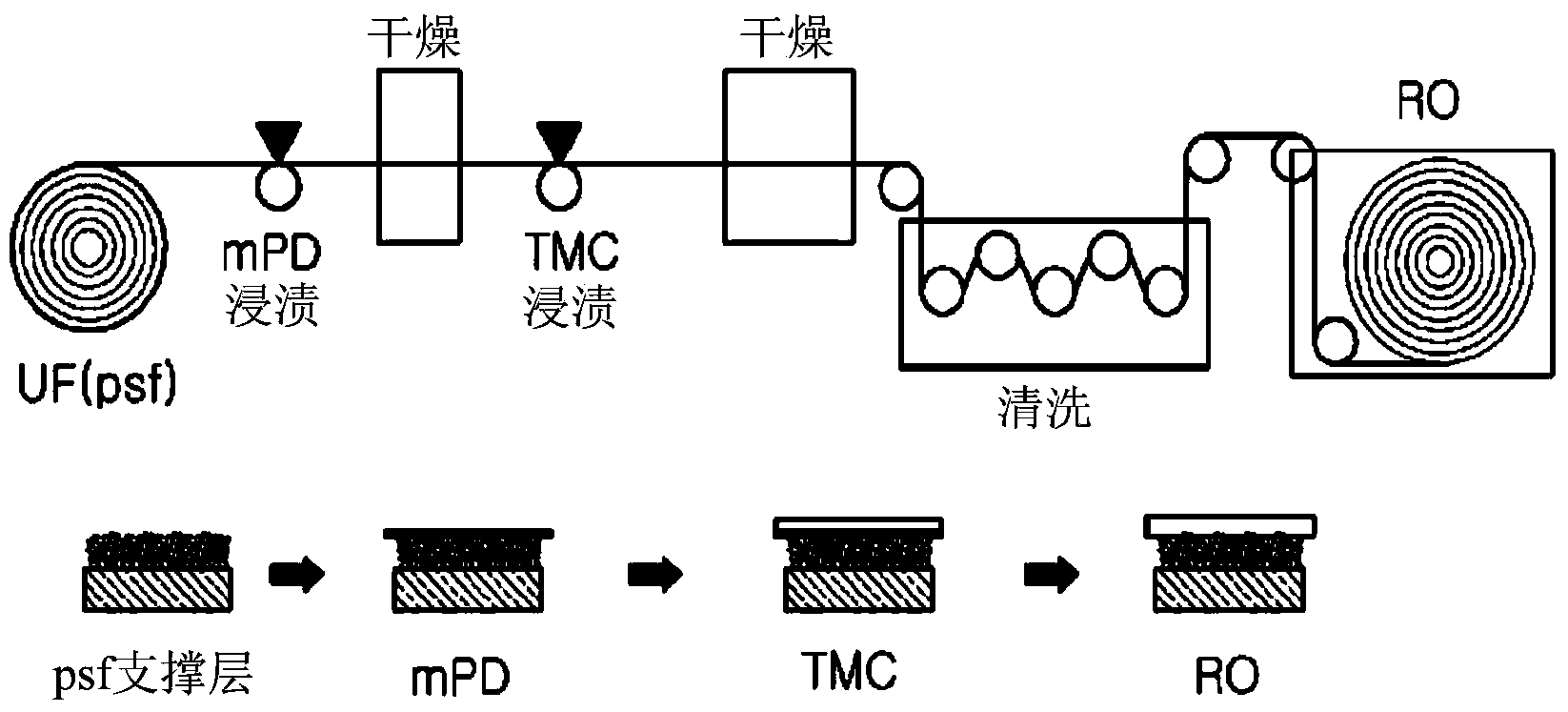

[0017] figure 2 The preparation process of the reverse osmosis membrane described in one embodiment of the present invention is shown. Such as figure 2 As shown, the preparation method of the reverse osmosis membrane described in one embodiment of the present invention can comprise: form the first coating by coating the aqueous solution of amine on the surface of the microporous support membrane; Remove from the microporous support membrane an aqueous solution of an excess of amine; and forming a second coating layer by coating an aliphatic hydrocarbon-based organic solution containing an acid halide on the first coating layer.

[0018] First, the first coating layer is formed by coating an aqueous solution of amine on the surface of the microporous support membrane.

[0019] In this case, the microporous support membrane can be formed by casting a polymeric material on a nonwoven. As polymeric materials, for example polysulfone, polyethersulfone, polycarbonate, polyethyl...

example 1

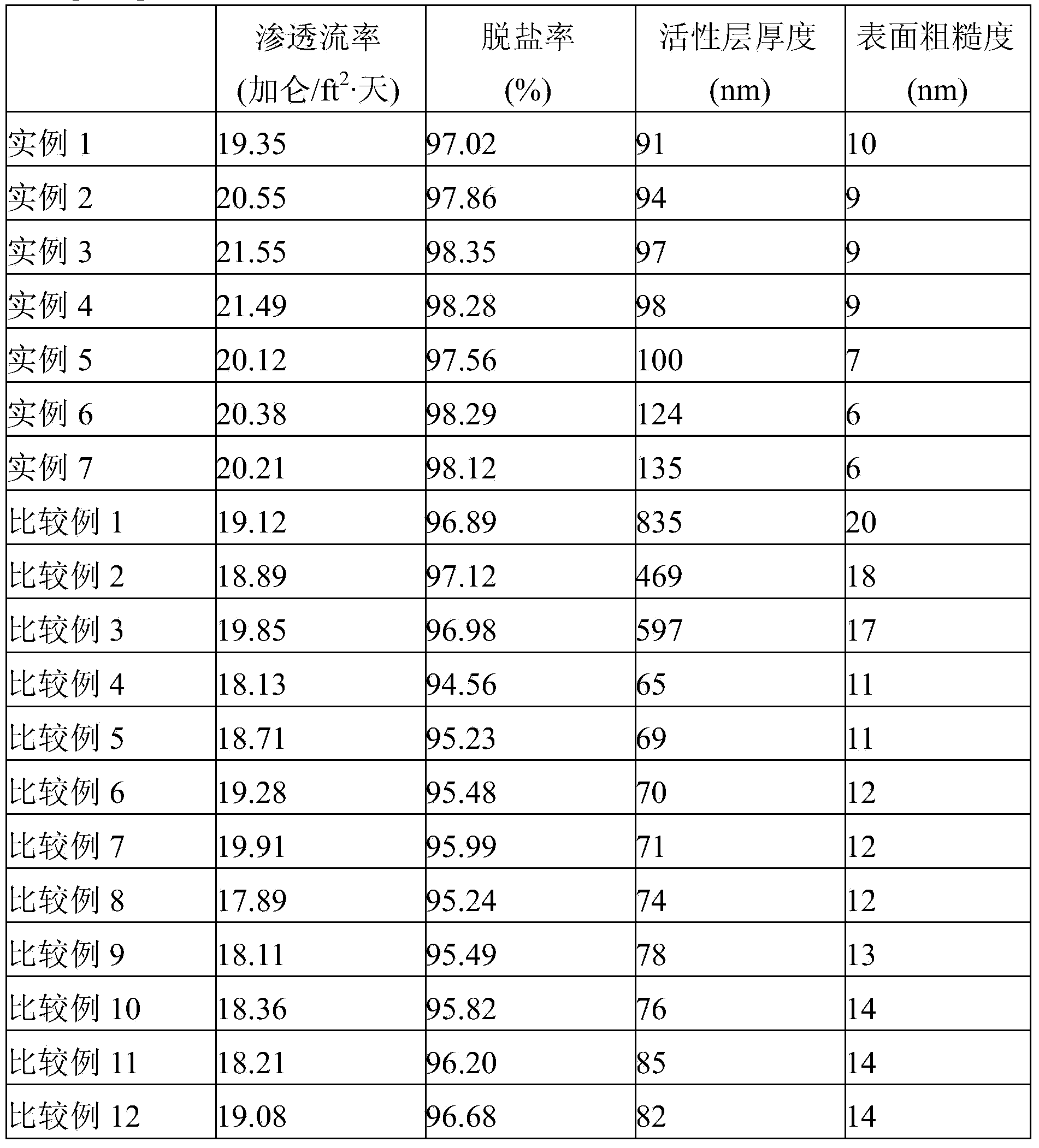

[0040] Use the sixth rod to coat a 2% (weight) m-phenylenediamine aqueous solution containing 1% (weight) triethylamine on a porous polysulfone support membrane cast on a non-woven fabric and having a thickness of 140 μm to form a 13.72 μm thickness of the first coat. After removing the excess aqueous solution of amine on the support membrane, a 0.1% by weight solution of organic trimesoyl chloride using an isoparaffin solvent was applied on the first coating using a twelfth rod to have a thickness of 27.43 μm , so as to form a second coating, and then dried in an oven at 60° C. for 10 minutes, and washed in a 0.2% (by weight) sodium carbonate aqueous solution at room temperature for 2 hours or more, thereby making a reverse osmosis membrane. After preparing the reverse osmosis membrane, the reverse osmosis membrane had an active layer with a total thickness of 91 nm and an average surface roughness of 10 nm.

example 2

[0042] A reverse osmosis membrane was prepared using the same method as Example 1, except that the ninth bar was used to coat the m-phenylenediamine aqueous solution to have a thickness of 20.57 μm, and the sixth bar was used to coat the organic trimesoyl chloride solution to have 13.72 μm thickness. After preparing the reverse osmosis membrane, the reverse osmosis membrane had an active layer with a total thickness of 94 nm and an average surface roughness of 9 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com