Battery pack

A technology for battery modules and battery groups, which is used in secondary battery charging/discharging, secondary battery repair/maintenance, etc., and can solve the problems of inconsistent internal resistance of battery cells, different polarization characteristics of battery cells, and inconsistent charging and discharging characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and preferred embodiments of the present invention.

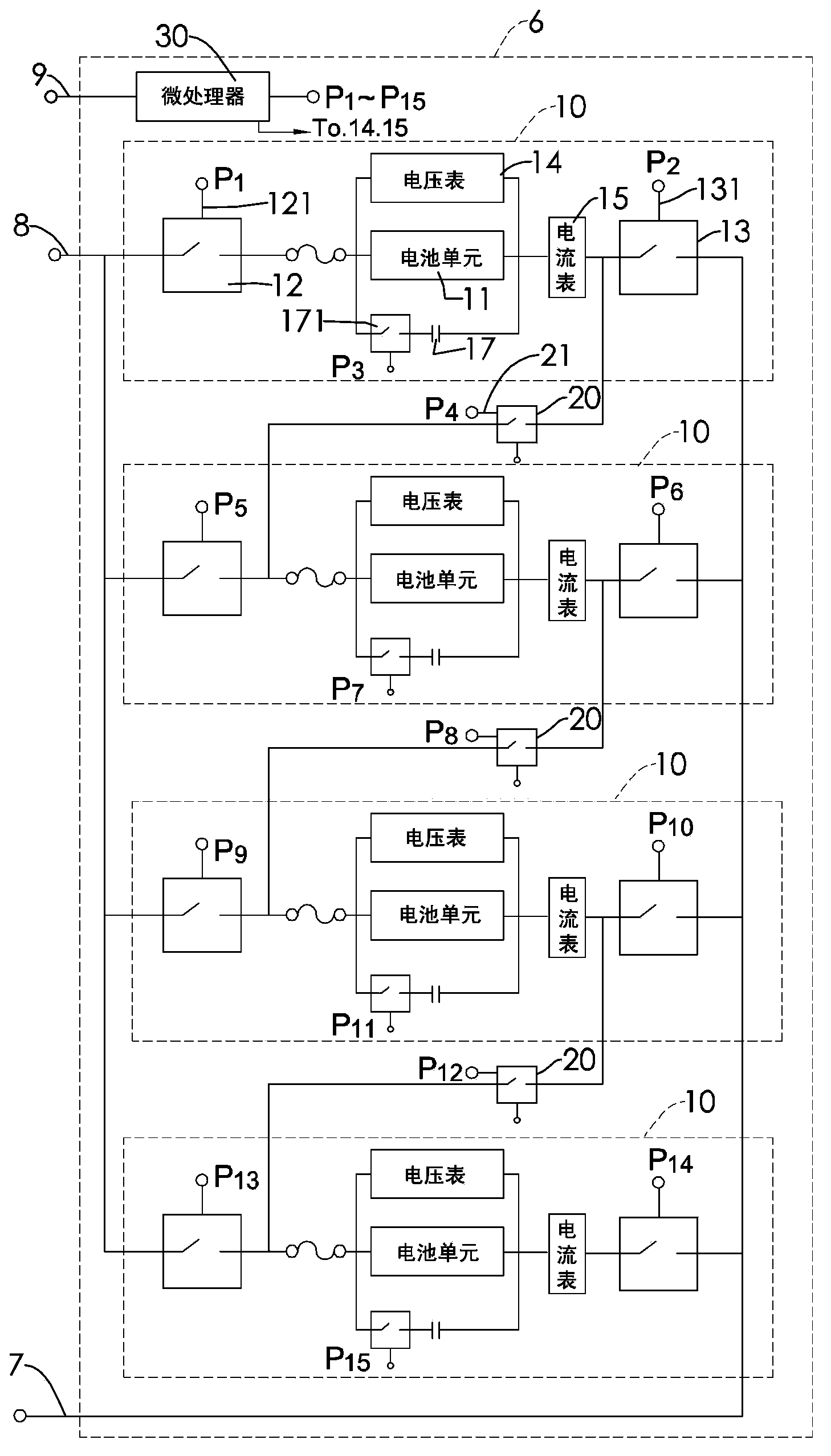

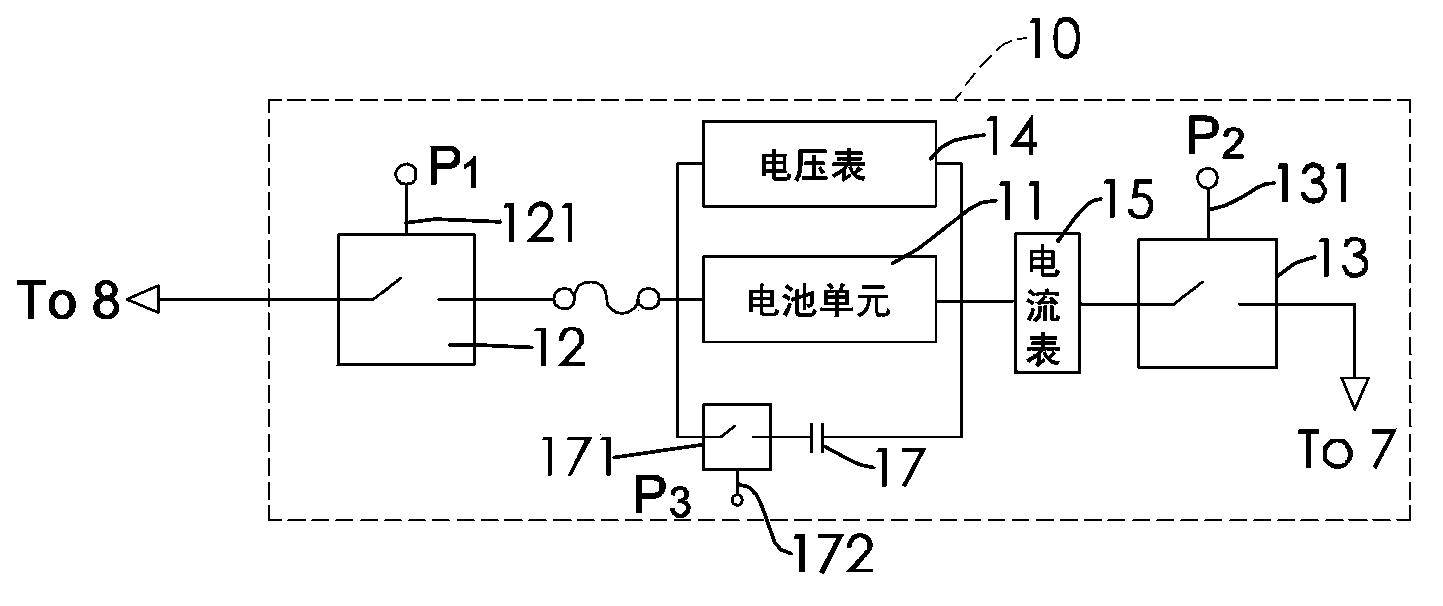

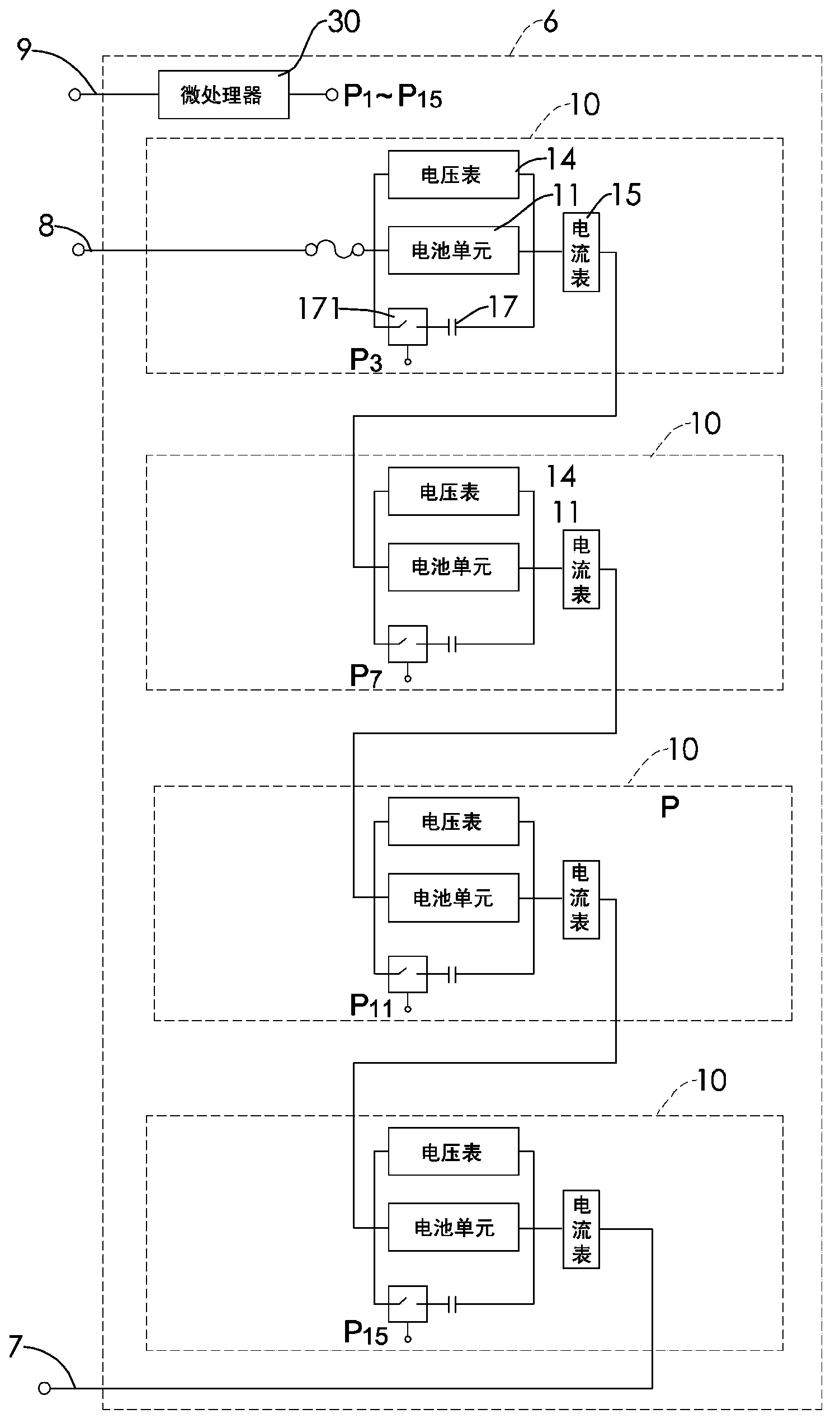

[0034] see figure 1 and figure 2 , the battery module 6 of the present invention has a cathode terminal 7, an anode terminal 8 and a control terminal 9, and includes:

[0035]A plurality of battery groups 10, each battery group 10 is connected to the anode terminal and the cathode terminal, and includes a battery unit 11, an electrical characteristic detection module, an anode switch 12 and a cathode switch 13; the battery unit has An anode and a cathode, the electrical characteristic detection module is connected to the battery unit 11 to detect the electrical characteristics of the battery unit 11, the anode switch 12 is connected in series between the anode of the battery unit 11 and the anode terminal 8 of the battery mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com