Heat pump drying device for water on surface of material

A technology of heat pump drying and surface water, applied in drying gas arrangement, progressive dryer, drying of solid materials, etc., can solve the problems of low space utilization efficiency and comprehensive application efficiency, unfavorable promotion, long drying cycle, etc. The inner temperature is too high, the dehumidification effect is good, and the adaptability is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

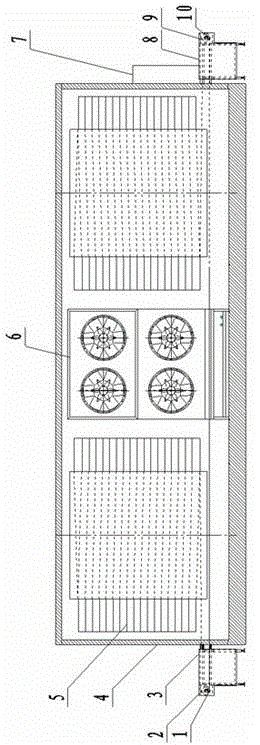

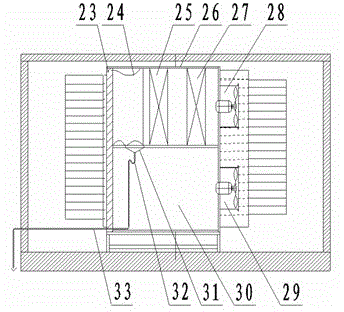

[0018] like figure 1 , 2 , 3, including the rolling bearing at the feed end 1, the feed gear mechanism 2, the feed device 3, the heat preservation storage body 4, the screw conveyor device 5, the drying medium treatment box 6, the electrical control box 7, the discharge device 8, the discharge Material gear mechanism 9, rolling bearing 10 at the discharge end, air guide assembly and heat pump system.

[0019] The thermal insulation storage body 4 has a built-in drying medium treatment box 6 and a screw conveyor 5 with a conveying mesh belt 20. The front and rear ends of the thermal insulation storage body 4 are provided with a feeding device 3 and a discharge device 8, both of which are used as the screw conveyor 5 in the feeding The outward extension of the end and the discharge end side, so that the material enters or moves out of the heat preservation storage body 2 after being placed on the conveyor belt. The end portion of feed device 3 and discharge device 8 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com