Armrest device in elevator car and armrest arranging method in the elevator car

An elevator car and handrail technology, which is applied to elevators, transportation, and packaging in buildings, can solve problems such as difficulty in ensuring safety, complexity, and unpredictable work efficiency, and achieves simple installation operations, improved safety, structure and efficiency. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

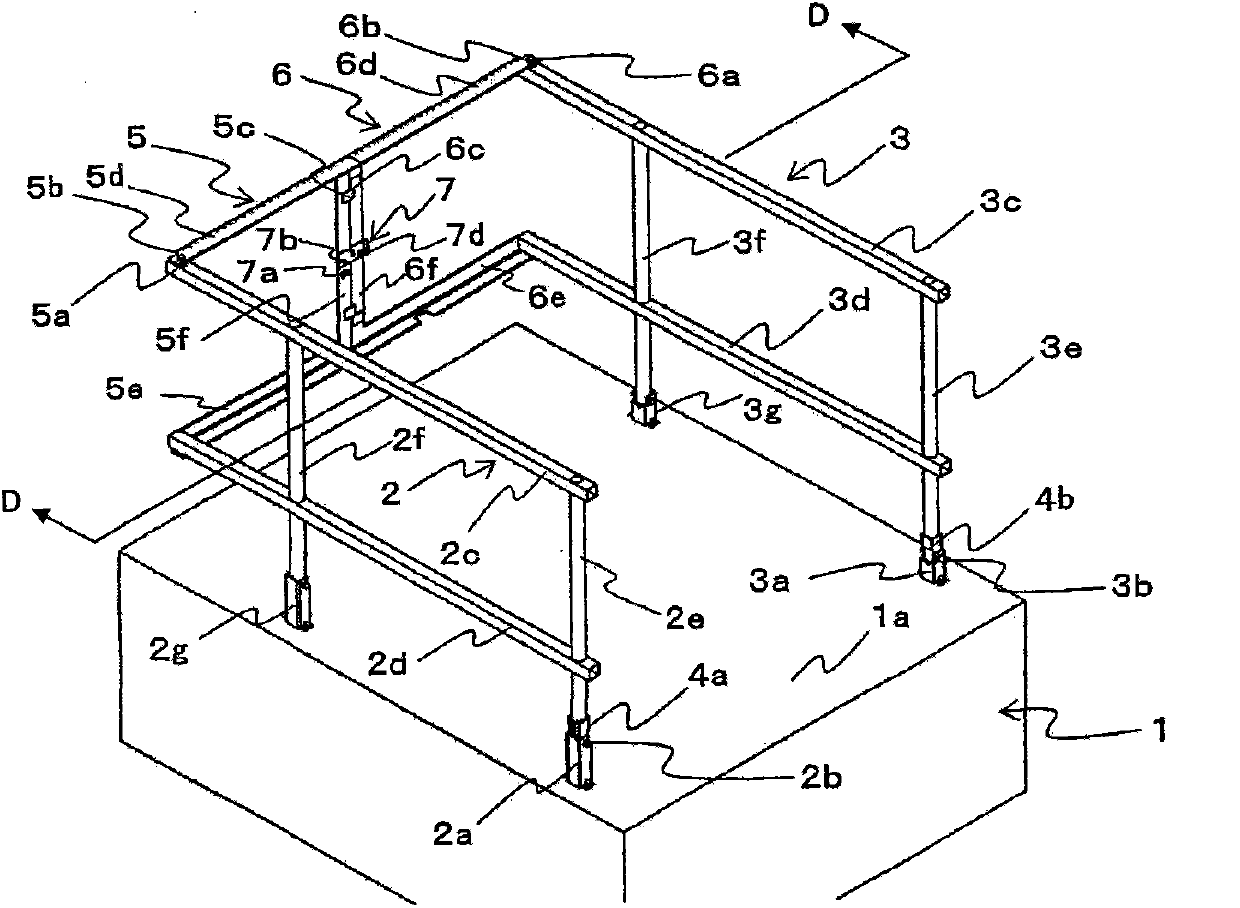

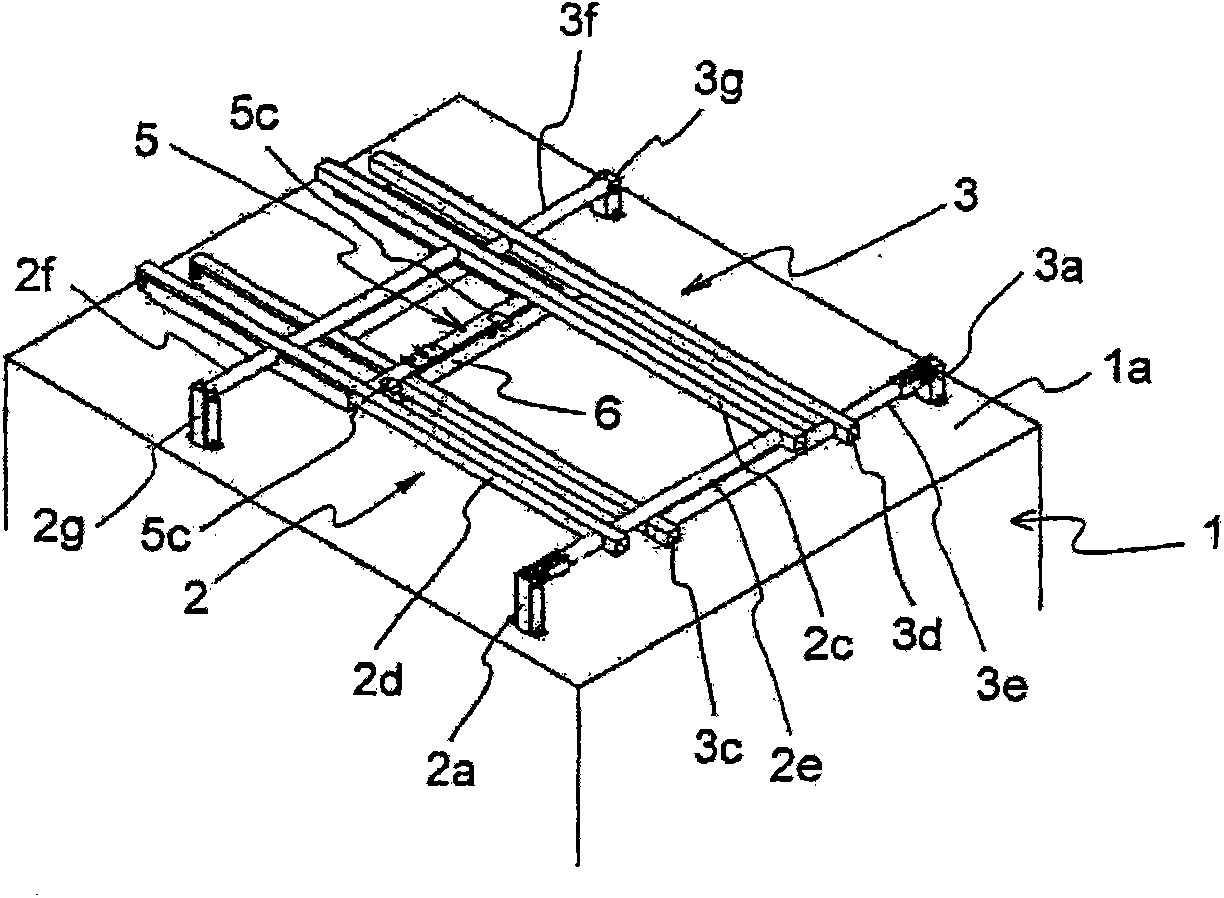

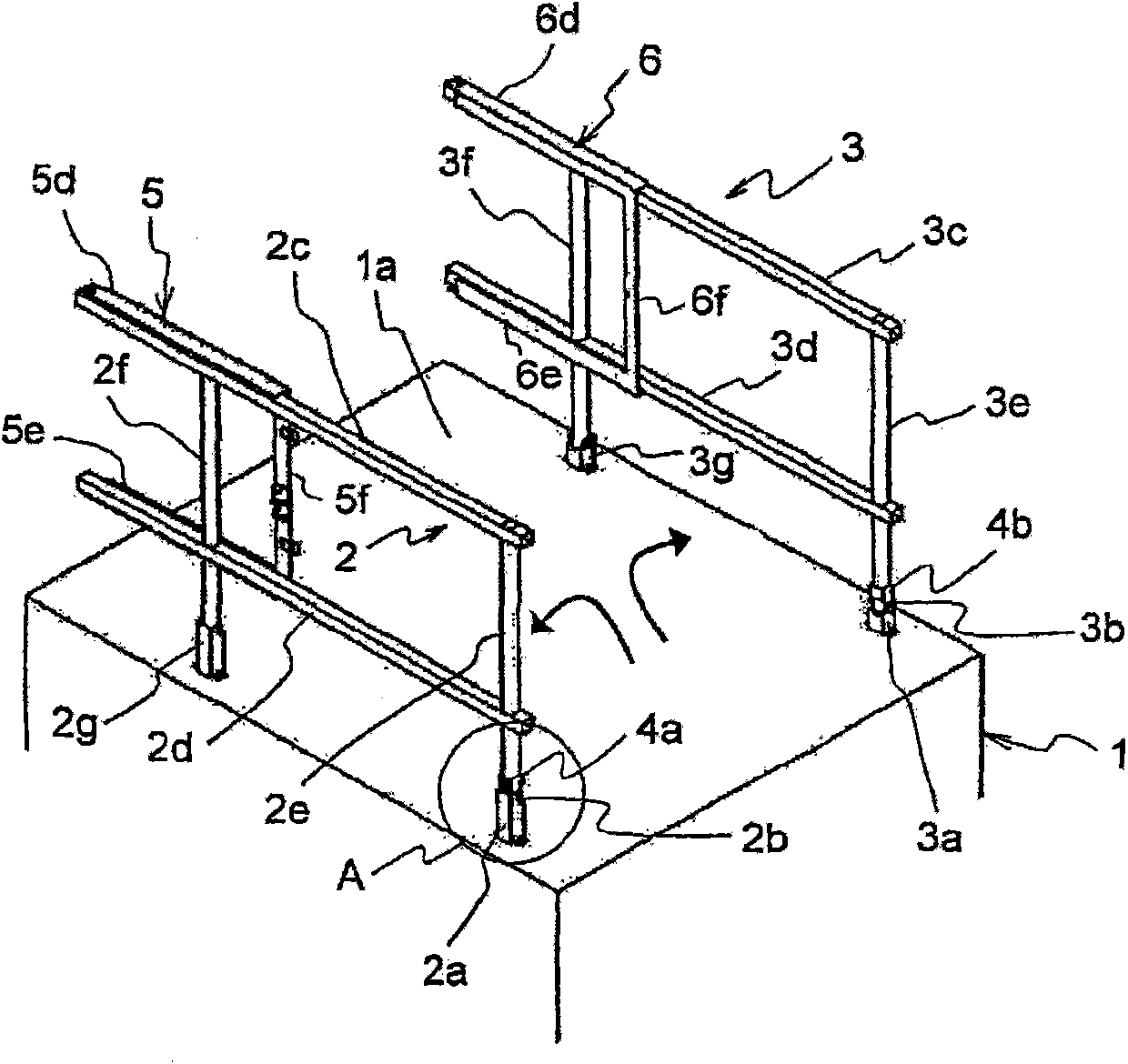

[0028] Hereinafter, embodiments of the handrail device for an elevator car according to the present invention will be described based on the drawings.

[0029] Such as figure 1 As shown, the handrail device for an elevator car according to this embodiment includes a left handrail 2 erected on the left side viewed from the landing side of the elevator, and a right handrail 3 erected on the right side viewed from the landing side. In addition, a rear armrest to be described later that connects the left armrest 2 and the right armrest 3 is included.

[0030] The left armrest 2 has, for example, a front vertical post 2e and a rear vertical post 2f, an upper stack 2c fixed to the front vertical post 2e and the rear vertical post 2f and disposed on the upper side, and a stack disposed on the lower side of the upper stack 2c. Middle stack 2d. Similarly, the right armrest 3 also includes, for example, a front vertical post 3e and a rear vertical post 3f, an upper stack 3c fixed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com