Sand and stone conveyor belt supporting frame

A conveyor belt and support frame technology, applied in the field of support frames, can solve problems such as the inability to realize the support frame, and achieve the effect of simple structure, simple operation, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

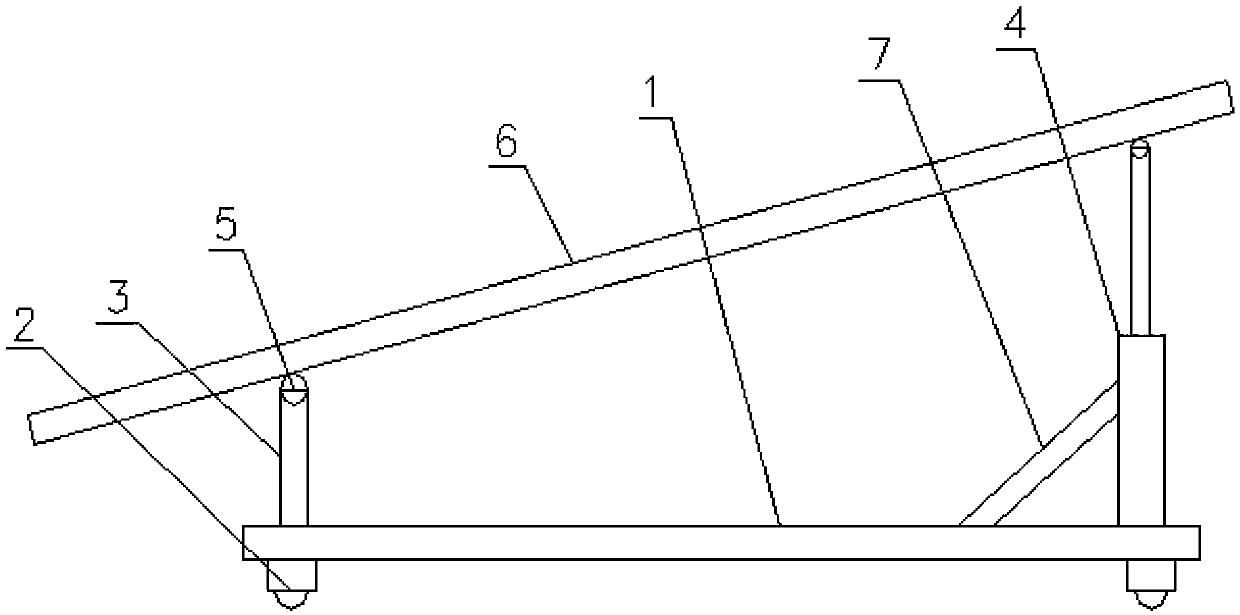

[0011] Such as figure 1 A support frame for a sand and gravel conveyor belt shown includes an underframe 1, a roller 2 is arranged below the underframe 1, a front bracket 3 is vertically provided at the front end of the underframe 1, and a telescopic support 4 is vertically provided at the rear end of the underframe 1, wherein The front bracket 3 and the telescopic bracket 4 are provided with movable connectors 5, and the movable connector 5 is provided with a transmission frame 6, wherein the telescopic bracket 4 is provided with an oblique connecting rod 7 connected to the underframe 1.

[0012] The basic principles, main features and advantages of the present invention have been shown and described above. Those skilled in the industry should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com