Flange track gravity automatic welder

A flange plate, gravity type technology, applied in the field of flange plate track gravity type automatic welder, to achieve the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

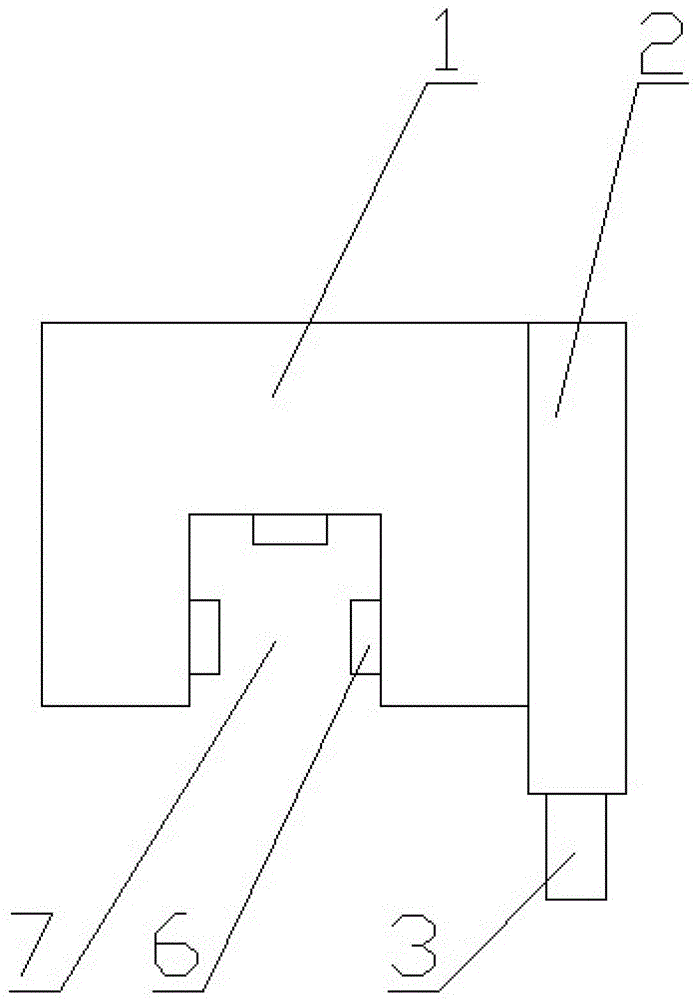

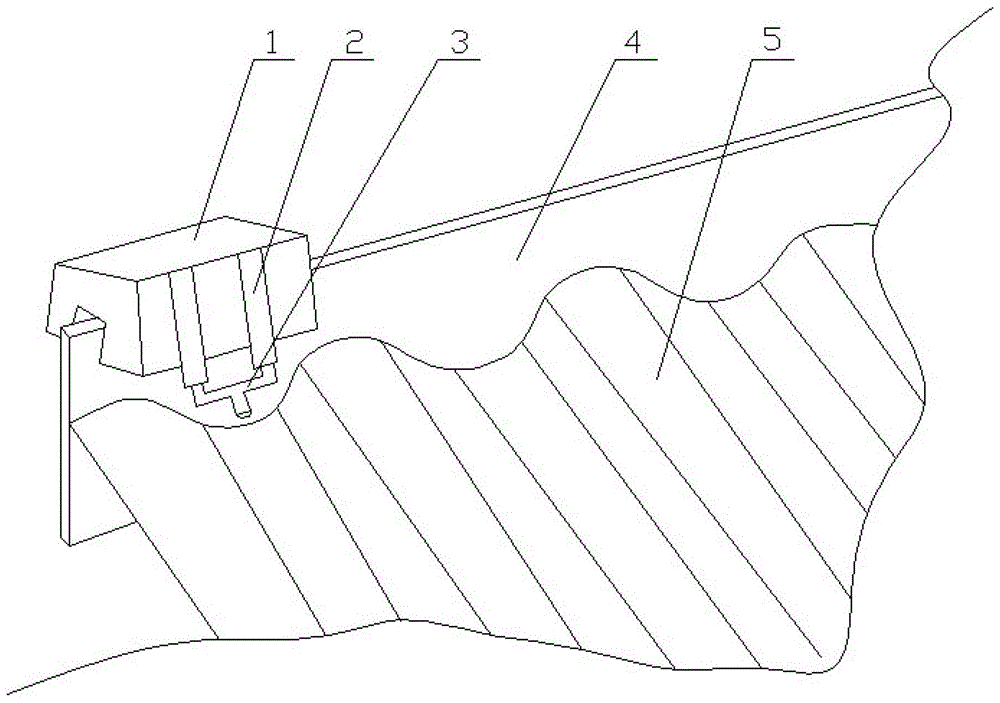

[0017] Flange track gravity automatic welder, including main frame 1, groove 7 on the main frame 1, wheels 6 in the groove 7; conduit 2 on one side of the main frame 1, conduit 2 and mobile support 3 connect.

[0018] The groove 7 is located at the bottom of the welding main frame 1 .

[0019] Each face of the inner wall of the groove 7 is provided with a wheel 6 .

[0020] Mobile support 3 is provided with welding torch.

[0021] The mobile support 3 is provided with a cleaner.

[0022] The main frame 1 is moved pneumatically, electrically or hydraulically.

Embodiment 2

[0024] Place the first flange track gravity automatic welder with welding torch on the mobile support 3 at the working position, when it starts welding and moves a distance of about 40cm-50cm, then set the cleaner on the mobile support 3 The second flange plate track gravity automatic welder is placed in the working position and starts cleaning work. After the second flange plate track gravity automatic welder moves about 40cm-50cm, place the other flange plate track gravity automatic welder equipped with a welding torch at the working position for re-welding, so as to achieve Requirements for multi-level welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com