Slurry shaker mixer

A mixer and slurry technology, which is applied in the directions of shaking/oscillating/vibrating mixers, mixers, dissolving, etc., can solve the problems such as prolonging the stirring time, stirring the jelly-like slurry that does not meet the technological standards, and low efficiency. Production efficiency, not easy to delaminate, and the effect of eliminating blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

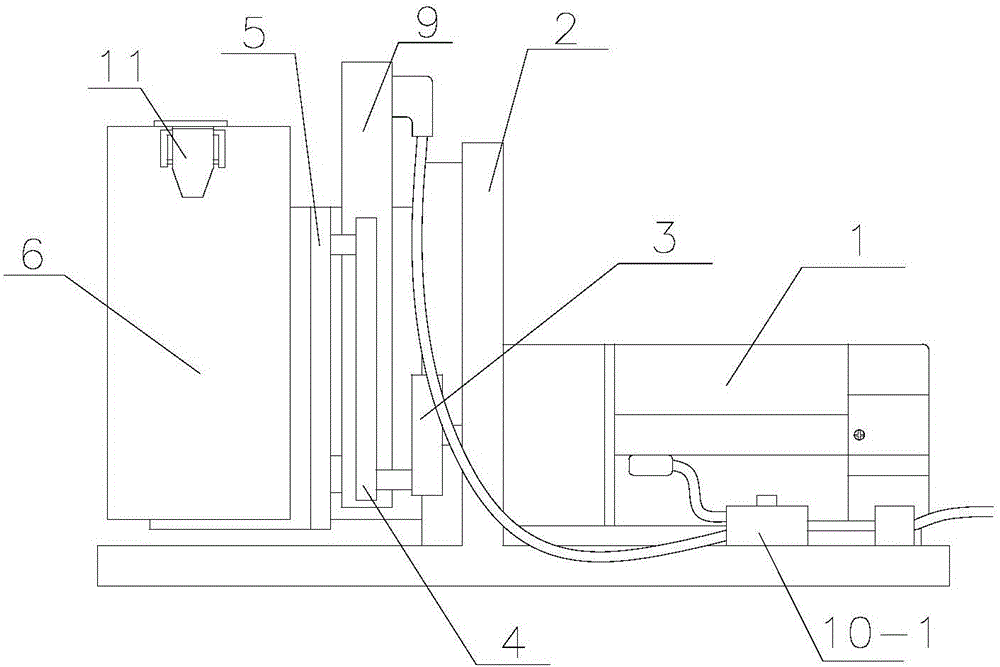

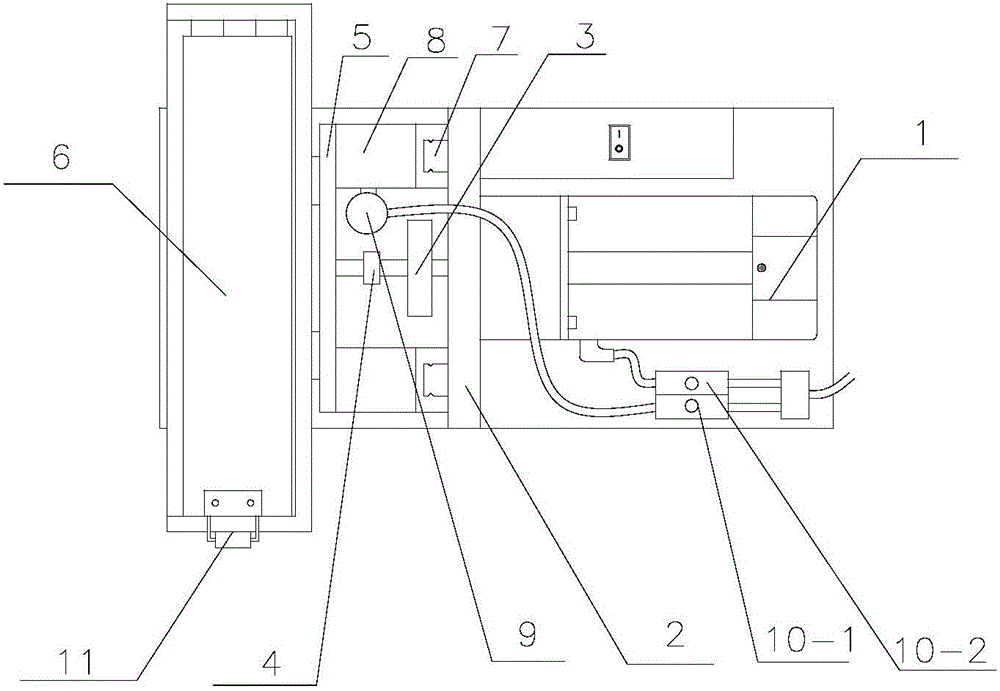

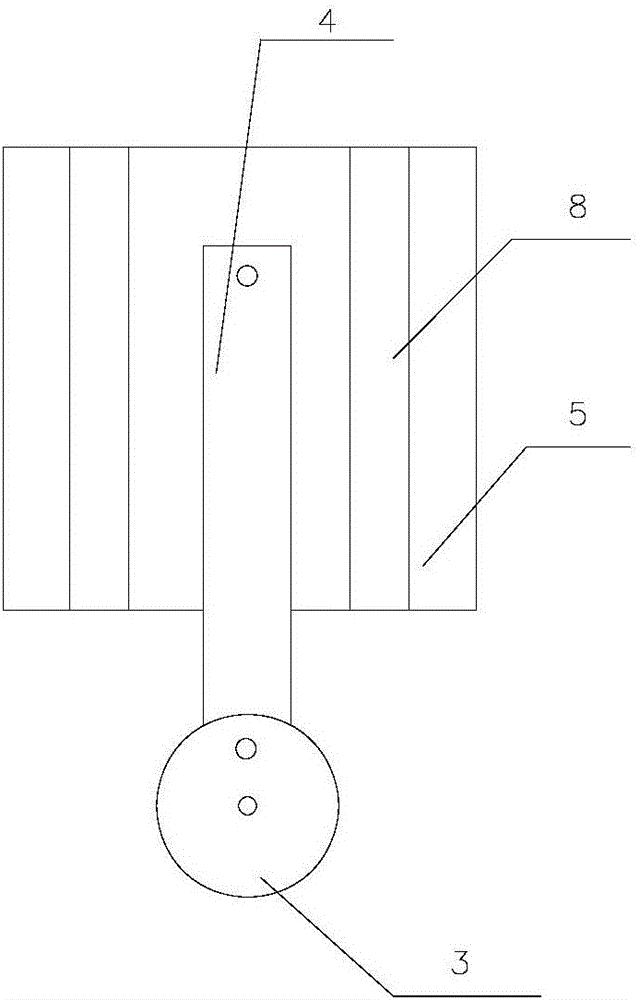

[0017] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0018] Such as Figure 1-3 As shown, the slurry vibrating mixer of the present invention includes a motor 1, a support plate 2, a motor disc 3, a rotating connecting rod 4, a fixed plate 5 and a shelving box 6 for placing a slurry bucket, and the output shaft of the motor 1 is facing the The support plate 2, the output shaft of the motor 1 passes through the support plate 2 and is connected to the center of the motor disk 3, the edge of the motor disk 3 is hinged with one end of the rotating link 4, and the other end of the rotating link 4 is hinged with the fixed plate 5 , the fixed plate 5 is fixedly connected with the storage box 6, the two sides of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com