Novel stirring paddles

A stirring paddle and a new type of technology, applied in the field of stirring paddles, can solve the problems of reducing the working life of the stirring paddle, reducing the uniformity of the material, and reducing the stability of the stirring paddle, and achieving the effects of simple structure, improved work efficiency, and reduced flow resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

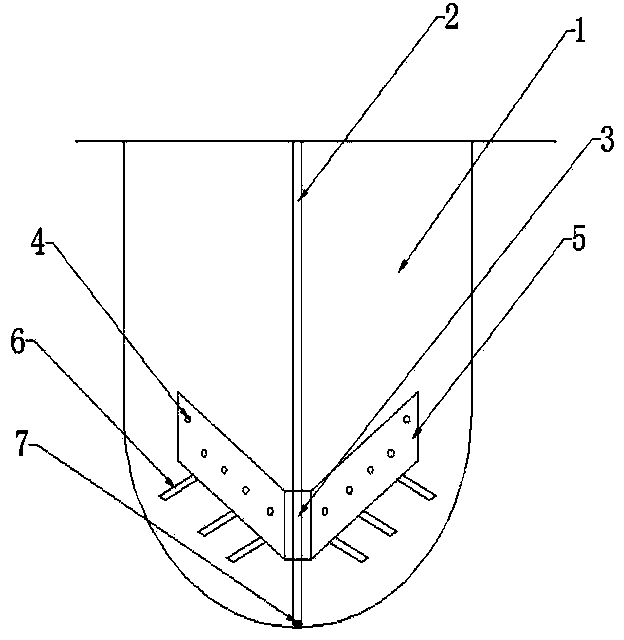

[0016] The present invention will be further described below in conjunction with the accompanying drawings. The mixing batching tank 1 is made of stainless steel and is used for holding materials. Stirring rod 2 is made of stainless steel, cylindrical in shape, with a spherical structure at the bottom, connected with a motor, and drives the rotation of the stirring paddle. The stirring paddle 3 is V-shaped, symmetrically arranged at both ends of the bottom side of the stirring rod 2, and is composed of a stirring blade 5 and a side piece 6, and a certain number of small holes 4 are opened on the stirring blade 5. The motor drives the stirring rod 2 in the stirring batching tank 1 to rotate. The stirring rod 2 and the stirring paddle 3 rotate at the same time. When the stirring blade 5 rotates, it contacts with the material to drive the mixing of the material. Stirring increases the uniform mixing speed of the material. When the viscous resistance of the material is large, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com