Tobacco separating needle-threading tobacco loading suspension device

A suspension device, separate technology, applied in the direction of tobacco, tobacco preparation, application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

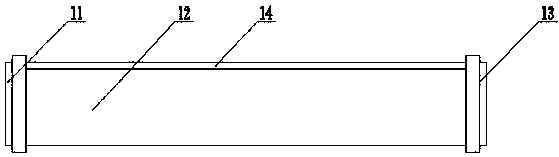

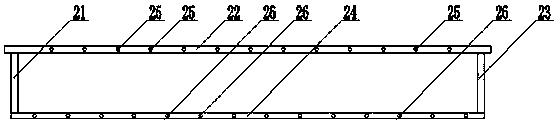

[0029] Such as Figure 1 to Figure 11 As shown, in an embodiment of the present invention, a tobacco leaf separation type needle-loaded tobacco suspension device includes a leaf basket (such as figure 1 , figure 2 , image 3 shown), the leaf-fixing hanger matched with the leaf basket separately (such as Figure 4 , Figure 5 , Figure 6 shown), tobacco leaf baffle 3 (such as Figure 7 shown) and retaining card 4 (as Figure 8 and Figure 9 shown),

[0030] The leaf-loading basket comprises a 220mm basket frame with a depth of 220 mm at the lower bottom edge opening surrounded by the left side plate 11, the upper top plate 12, and the right side plate 13, and an upper support rod 14 and a middle support rod 15 are arranged outside the back side of the basket frame. 1, three support rods of lower support rod 16,, three support rods are fixedly connected with left side plate 11, right side plate 13 respectively, three support rods are arranged in parallel, leave gap mutu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com