Electric motor drive

A driving device and motor technology, applied in the direction of electromechanical devices, electric components, and control/drive circuits, etc., to achieve the effect of firm fixation, compact motor drive device, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

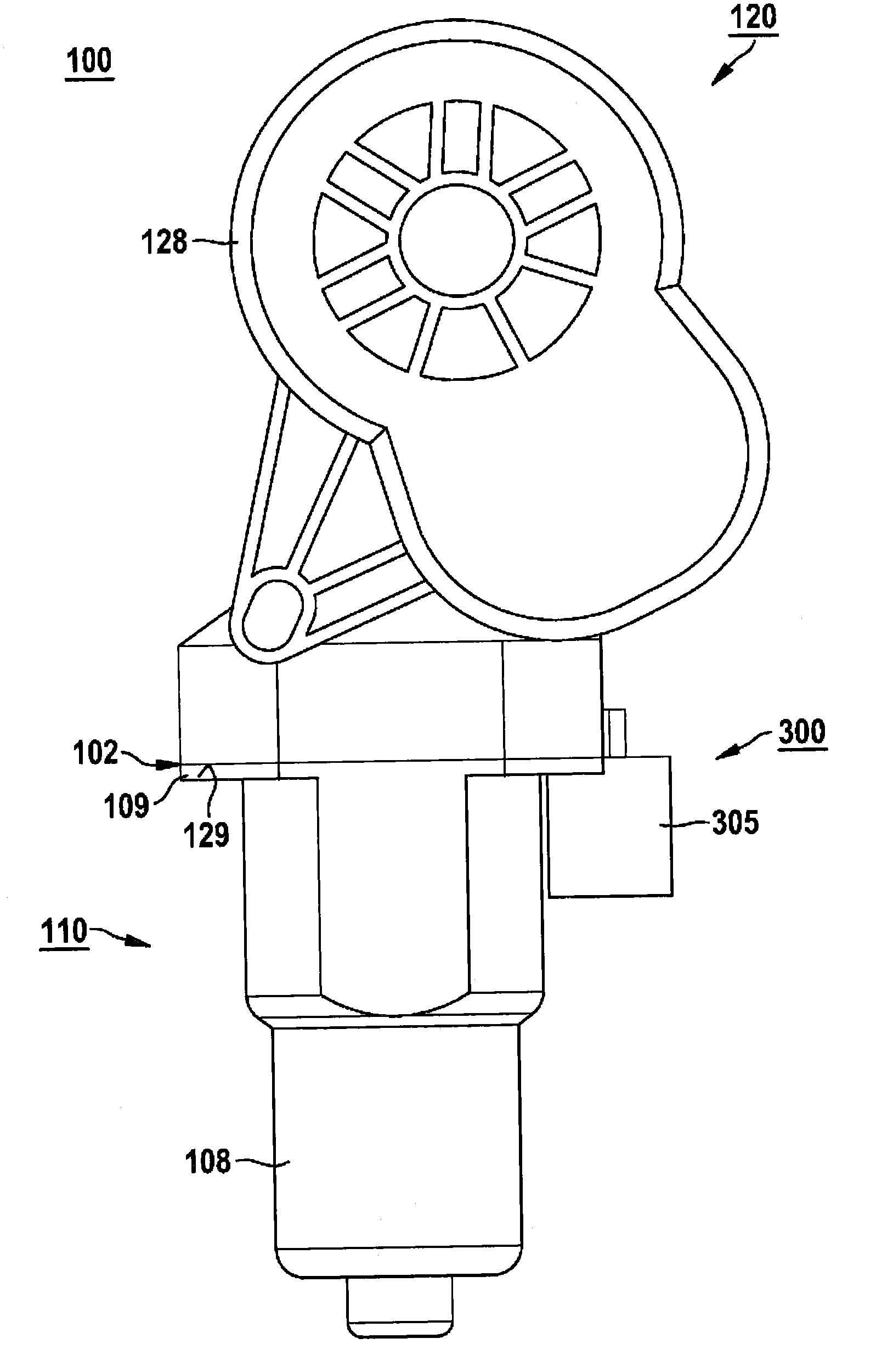

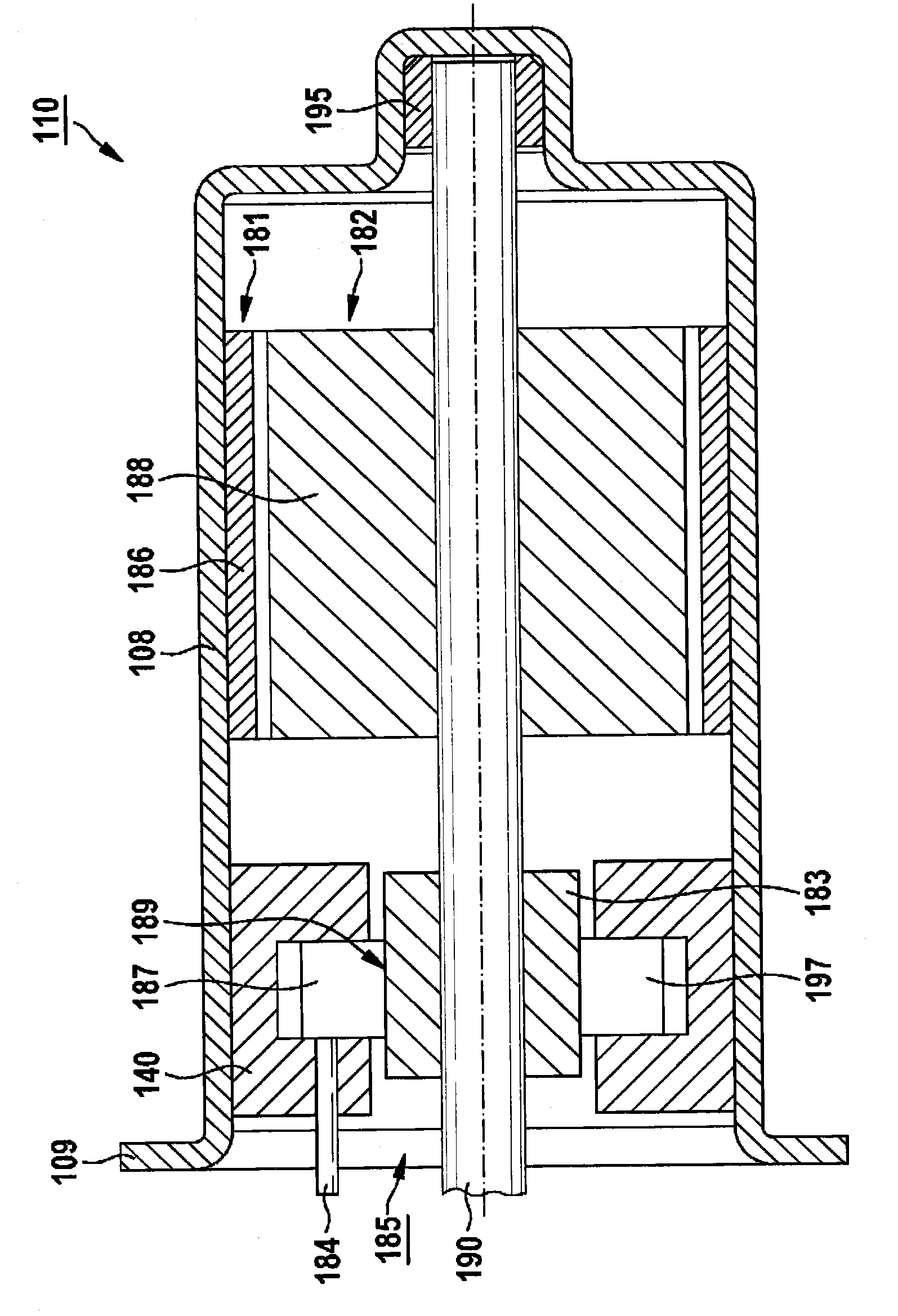

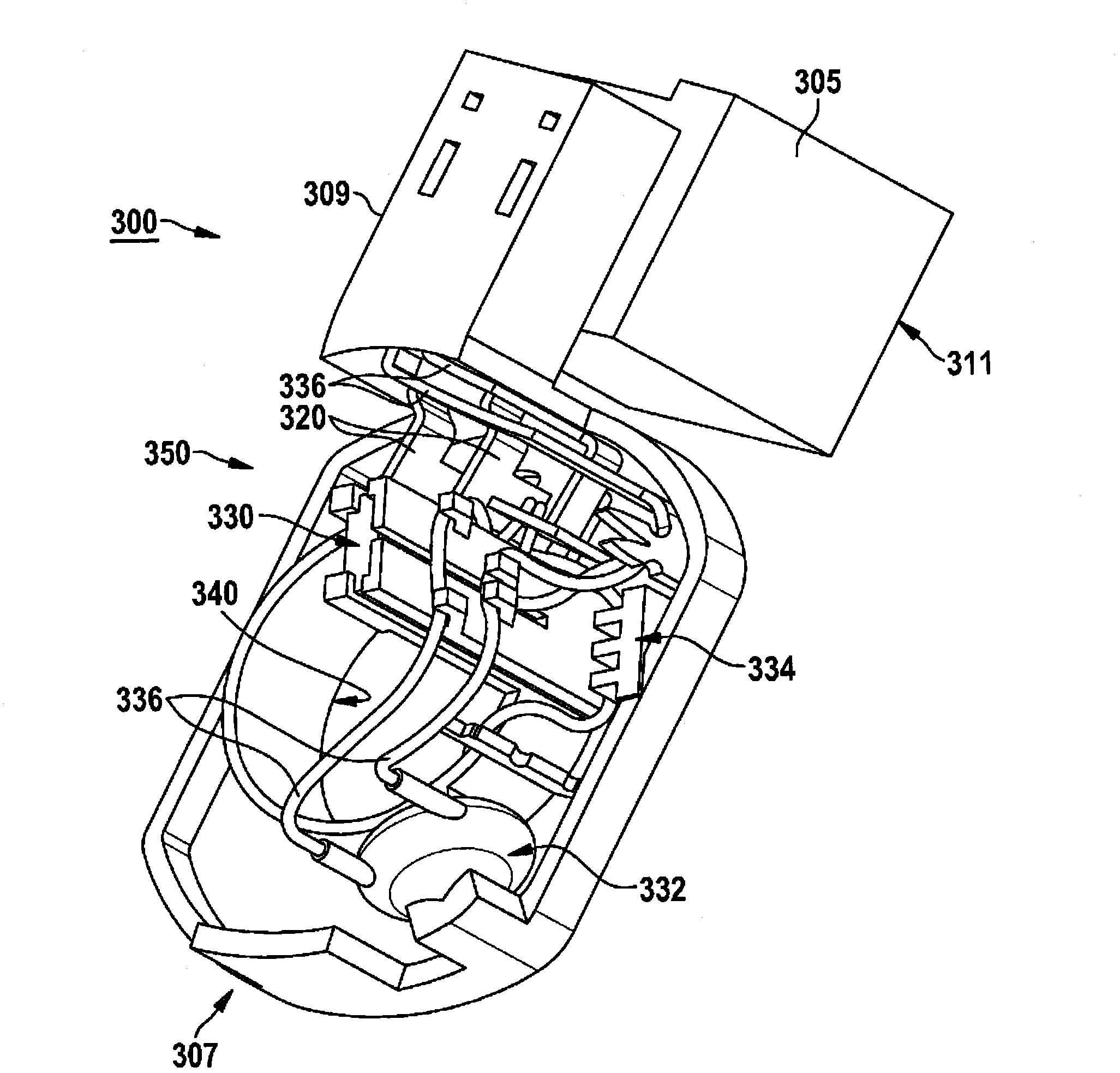

[0036] figure 1 According to one specific embodiment, an electric motor drive 100 is shown with an electric motor 110 and a transmission 120 drivable by the electric motor, which can be used, for example, as a window lifter, a seat adjustment device and / or in a motor vehicle. Drive unit for windshield wipers. The electric motor 110 is shown equipped with a motor housing 108 having a fixing flange 109 . The transmission 120 is equipped, for example, with a transmission housing 128 which has a fastening section 129 .

[0037] According to one embodiment, the fastening flange 109 of the motor housing 108 is fastened to the fastening section 129 of the transmission housing 128 , for example screwed, riveted, welded, glued or fixed in any other manner. Section 129 on. In this case, the motor housing 108 and the transmission housing 128 form an interface 102 with one another at the transition, at which interface the two housings 108 , 128 bear against each other.

[0038] As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com