Enameled wire coil rack descending method

A technology of enameled wire and wire reel, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of reducing labor intensity, achieve the effects of reducing labor intensity, saving labor costs, and not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A method for removing an enameled wire tray, the method comprising the following steps:

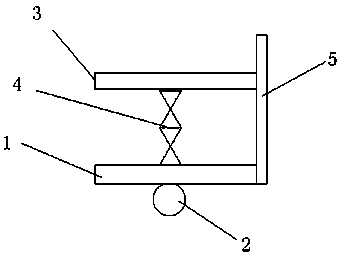

[0015] 1) After the take-up reel is full, push the special tool cart under the take-up reel. The special tool cart is made of iron. See figure 1 , including base plate 1, wheels 2, liftable plate 3, hydraulic lift arm 4 and cart handle 5, wheel 2 is arranged below base plate 1; the lower end of hydraulic lift arm 4 is set on base plate 1, and the upper end of hydraulic lift arm 4 is connected with The liftable plate 3 is connected and arranged at the bottom central area of the liftable plate 3 . A chute is provided on the cart handle 5, and one end of the liftable plate 3 is arranged in the chute and can move up and down along the chute.

[0016] 2) Raise the hydraulic lifting arm of the special tool cart, raise the liftable plate, and hold up the wire reel;

[0017] 3) After pushing the special tool cart to the set position, lower the hydraulic lift arm, lower the liftable pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com