Device and method for measuring elasticity modulus of metallic material

A technology of elastic modulus and metal materials, applied in the direction of applying stable tension/compression to test the strength of materials, etc., can solve problems such as the existing literature that has not found the closest invention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

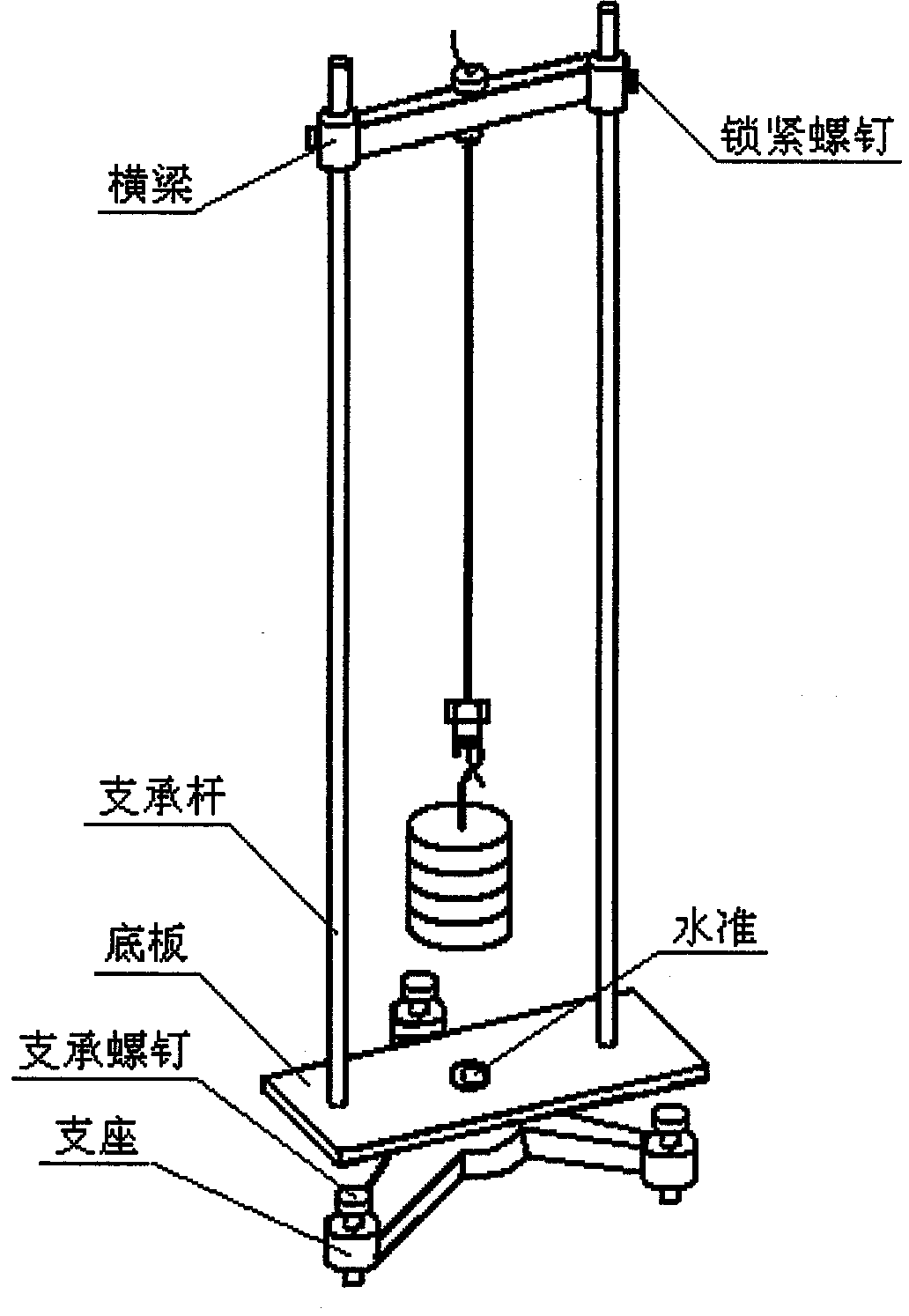

[0031] Device for measuring elastic modulus of carbon steel wire

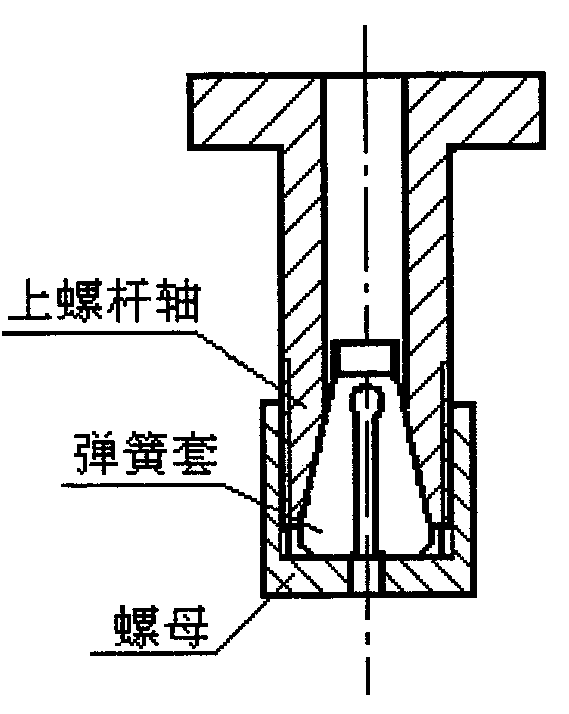

[0032] in figure 1 In, the device for measuring the elastic modulus of carbon steel wire includes bracket, weight, tray, upper chuck, lower chuck, measuring clamp and QJ44 DC double-arm bridge, with a range of 0-25mm spiral micrometer, and the range is 0-2000mm tape measure, including conductivity coefficient ρ=9.70×10 -8 Ω·m, the carbon steel wire to be tested with a diameter of 0.635mm, the carbon steel wire is about 1100mm long, and the detection section l is set to 900mm; figure 2 In the device for measuring the elastic modulus of carbon steel wire, the outer contour of the support is 2000mm high and 200mm wide; the support has three legs, and each foot end is equipped with a support screw. The support material is cast iron and the support screw material is 45 steel. The bottom plate and the support are connected with screws and fixed on the support. The middle of the bottom plate is equipped with a level. The...

Embodiment 2

[0041] Device for measuring elastic modulus of copper wire

[0042] The conductivity coefficient of the copper wire to be tested in the device for measuring the elastic modulus of copper wire ρ = 1.72×10 -8 Ω·m, the diameter is 1.362mm, the length is 1200mm, the detection section l is set to 1000mm, and two wires with a cross-sectional area of 2.5 square millimeters and a length of 1100mm are used. One end of the wire is 3.5 in diameter from a measuring clip Insert the screw into the hole with a diameter of 3.5 mm, screw one end of the wire to the curved surface of the measuring clip, and then pass one end of the other wire through the 3.5mm diameter hole of the other measuring clip, and screw it. Screw one end of the wire and the arc of the measuring clip tightly, and the other ends of the two wires are connected to the P1 and P2 potential terminals of the DC double-arm bridge; use two 2.5 square millimeters, 60mm long wires , Connect the two ends of one wire to the P1 potenti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com