Lead screw guiding device

A guide device and lead screw technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inaccurate positioning and guidance, complex guide device structure, difficulty in meeting the coaxiality requirements of the force axis and the host axis, and achieve Simple structure, friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

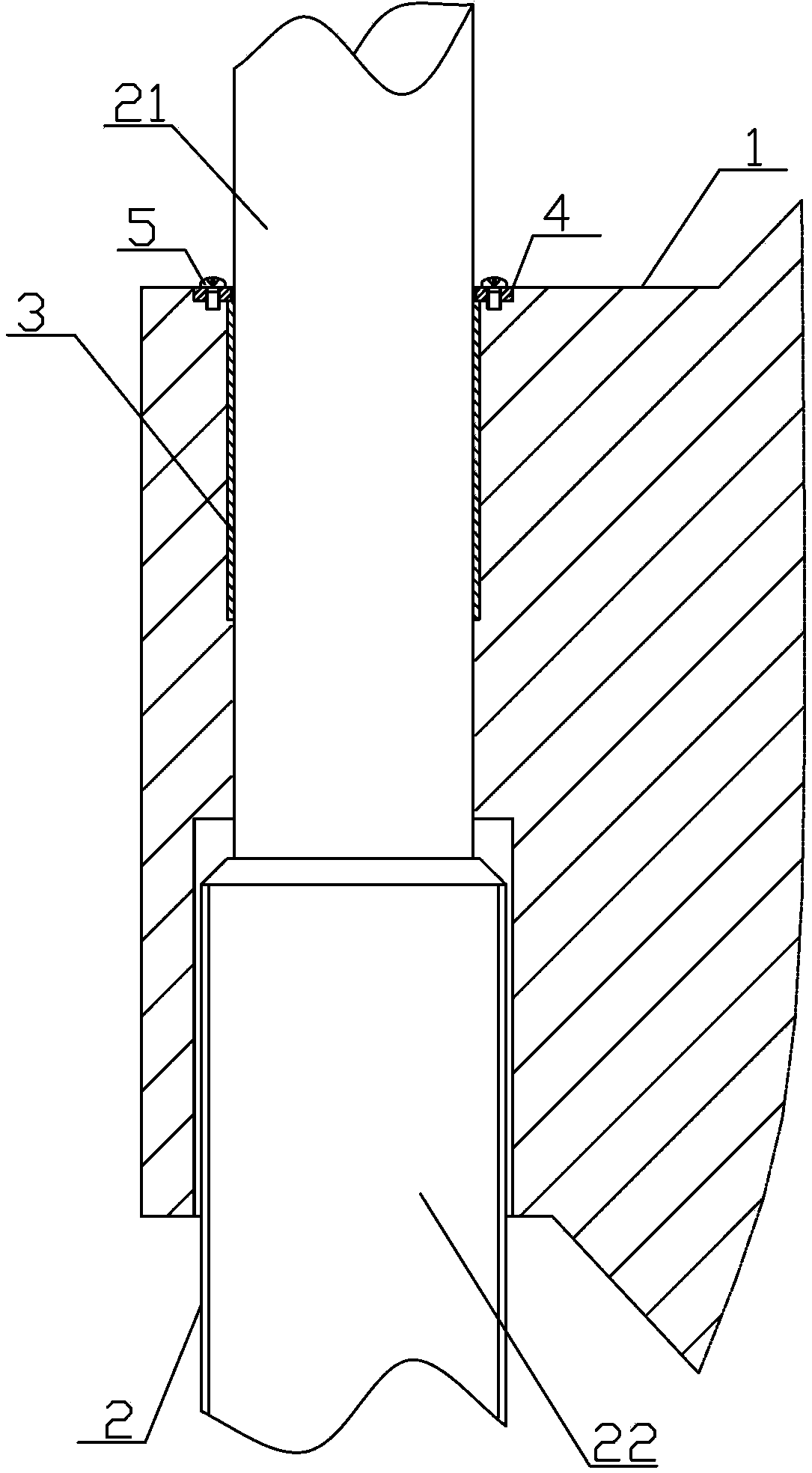

[0009] Such as figure 1 As shown, the screw guiding device of the present invention includes an upper beam 1 and a screw 2. The screw 2 includes a positioning shaft part 21 and a threaded part 22 of the screw. The guide positioning hole, the positioning shaft part 21 is arranged in the guide positioning hole, the inner upper end of the guide positioning hole is provided with a bearing hole, the self-lubricating bearing 3 is installed in the described bearing hole, and the upper end of the self-lubricating bearing 3 is provided with Bearing end cover 4, said bearing end cover 4 is fixedly connected with upper beam 1 by screws 5.

[0010] During the process of the upper beam moving up and down along the positioning shaft, the inner hole of the self-lubricating bearing is always in contact with the outer circumference of the positioning shaft, which ensures that the upper beam always moves along the axis of the screw and satisfies the stress on the sample during the test. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com