Single and low-air-permeability coal bed gas control method

A coal seam gas and gas permeability technology, applied in the field of underground safety, can solve the problems of difficult gas extraction, frequent and single gas exceeding the limit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

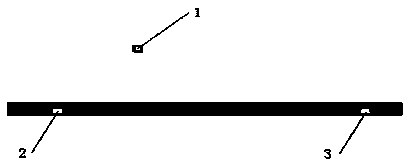

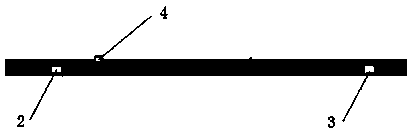

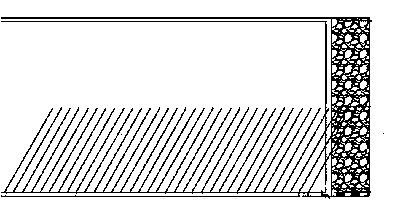

[0016] Such as figure 1 , 2 , 3 shows a single, low permeability coal seam gas control method,

[0017] 1) Establish a high-level gas drainage lane. The high-level gas drainage lane is located on the roof of the middle sandstone layer, with a horizontal distance of 32 meters from the return air lane and a vertical height of 27 meters from the coal seam roof. The cross-section of the high-level gas drainage lane is 3.5mx2. 8m;

[0018] 2) When one end of the high-level gas drainage roadway is 80 meters away from the cut hole, excavate down along the horizontal angle of 10° to the second layer of siltstone on the roof of the coal seam; the other end of the high-level gas drainage roadway stops mining at the working face of the coal seam When the line is parallel to the position, the oblique downward excavation is connected with the belt lane, and an exhaust fan is installed at the connection port;

[0019] 3) Establish a half-coal rock roadway, the horizontal distance of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com