Small-diameter tubular pump pump-passing depth checking perforating and pumping combined production method

A tubular pump and small-diameter technology, which is applied in the direction of production fluid, earthwork drilling, measurement, etc., can solve the problems of perforation position deviation, affecting oil production, prone to blowout, etc., achieve large pump gun distance and shorten oil production cycle , the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

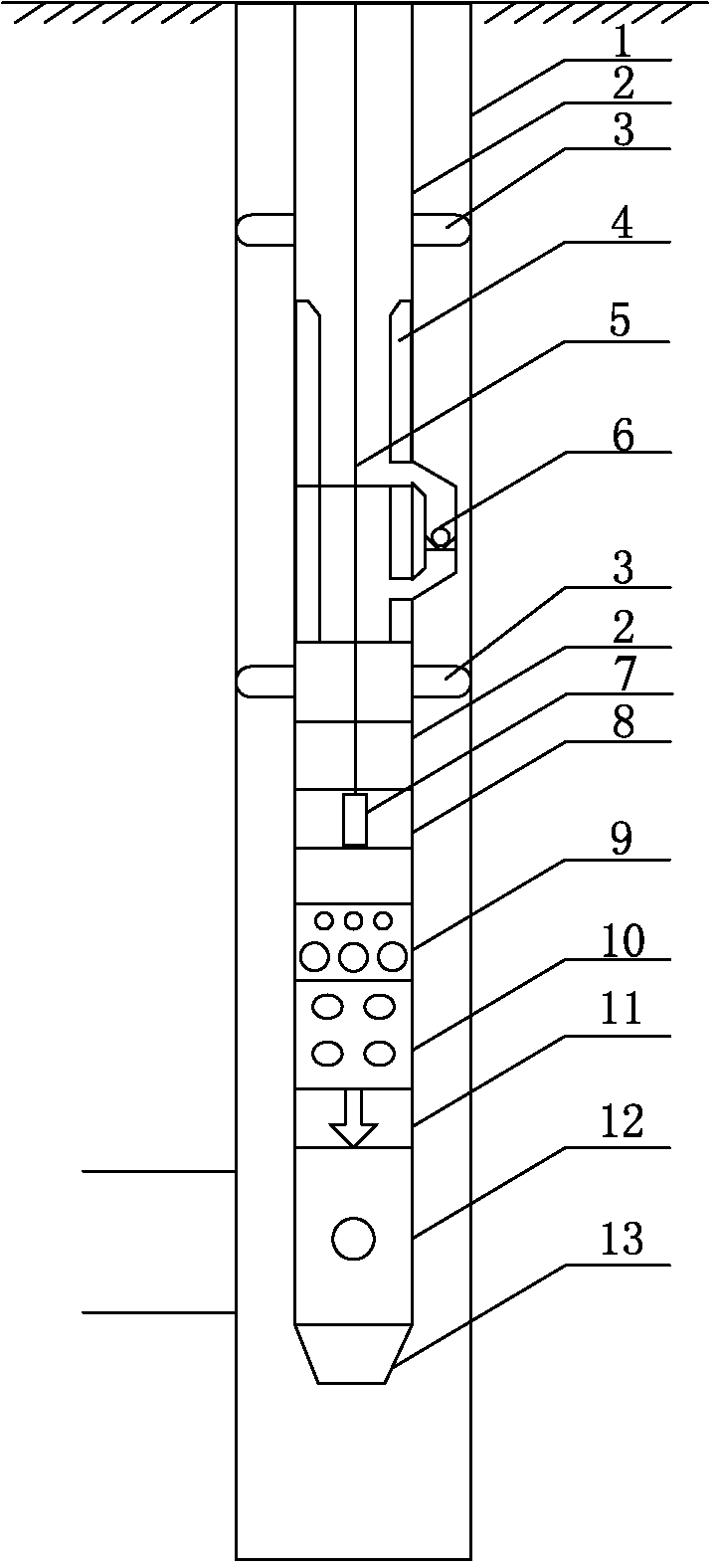

[0019] Such as figure 1 and figure 2 Shown respectively is a kind of small-diameter tubular pump of the present invention through the pump to correct the depth of the joint production method of shooting depth and the pipe column structure of the joint operation of shooting and production. The method of the present invention comprises the following steps:

[0020] a) Drill the well with well cleaning tools, remove the mud in wellbore 1, manually explore the bottom of the well, and test the pressure of wellbore 1;

[0021] b) Inject the production string into the wellbore 1 at a uniform speed, so that the pump is located at the designed pump hanging depth, and the structure of the string includes, from bottom to top, fixedly connected epilogue shells 13, φ102 perforating gun 12, pressure detonator 11, reinforced screen 10, gas anchor 9, φ73 tubing 2, magnetic positioning nipple 8, φ73 tubing, injection-production combined pump and φ73 tubing until they reach the wellhead,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com