Core machine ration sand adding method and device

A core-making machine and sand-filling cover technology, applied to molding machines, manufacturing tools, parts of molding machines, etc., can solve problems such as operation failure of reversing mechanism, overflow of molding sand, leakage of molding sand, etc., so as to avoid adverse effects and improve The effect of the service life and the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

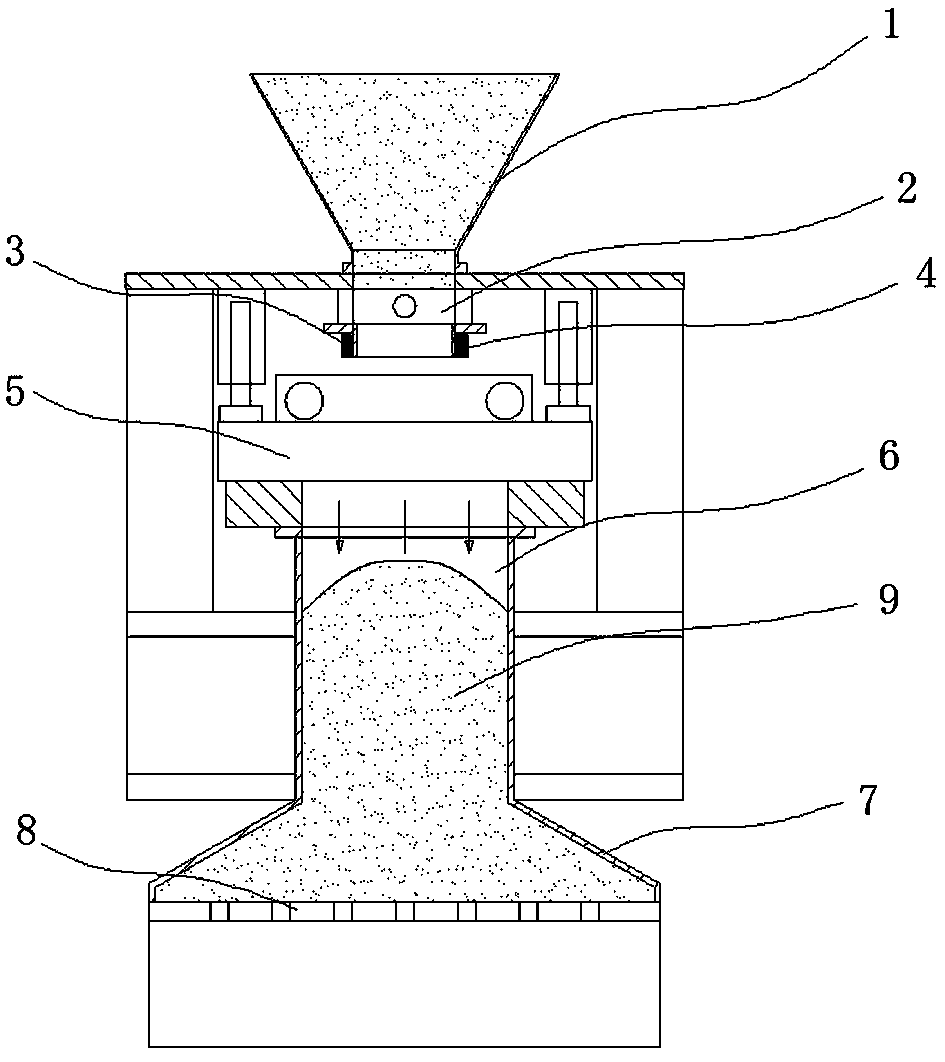

[0024] Embodiment one: see figure 1 and figure 2 As shown, a quantitative sand adding device for a core making machine includes a sand storage bucket 1, a sand filling butterfly valve 2 arranged below the sand storage bucket 1, a sand injection chamber 6 located below the sand filling butterfly valve 2, and a control mechanism. The sand-shooting chamber 6 forms a sand-shooting mechanism together with the shooting head 7 and the shooting plate 8, and sand 9 is arranged in the sand-shooting chamber.

[0025] A sand-filling moving mechanism 5 is provided below the sand-filling butterfly valve 2. The sand-filling moving mechanism 5 includes a sand-filling cover 10 and a driving device that cooperate with the top channel of the sand-shooting chamber. The sand-filling cover 10 has two working positions. At the sanding working position, the sanding cover 10 is located between the sanding butterfly valve 2 and the sanding chamber 6, and communicates with the outlet of the sanding bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com