Passenger vehicle steering knuckle precise forging die for hammer forging

A technology for precision forging and passenger cars, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc. It can solve the problems of difficult demoulding, poor surface quality of forgings, and short die life. To achieve the effect of convenient installation and adjustment, high precision forging and good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

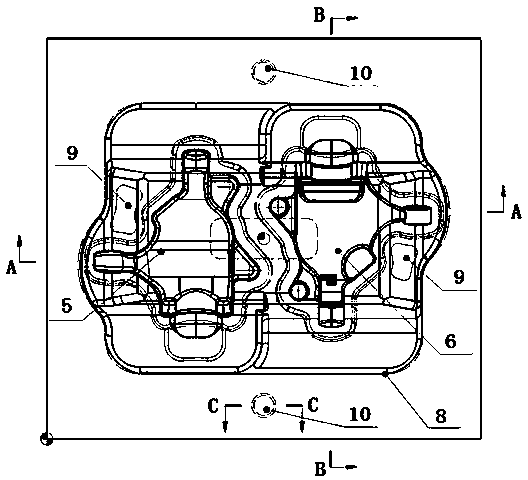

[0027] See Figure 1-5 , a passenger car steering knuckle precision forging die for hammer forging, comprising a forging upper die 1 and a forging lower die 2 both of which have a rectangular cross section, and two processing positioning pins are arranged on the forging upper die 1 and the forging lower die 2 hole 10 and a forging hammer mounting pin hole 11;

[0028] Forging upper die 1 is provided with pre-forging upper cavity 3 and final forging upper cavity 4 (see Image 6 ), the forging lower die 2 is provided with a pre-forging lower cavity 5 matching with the pre-forging upper cavity 3, and a final forging lower cavity 6 matching with the final forging upper cavity 4 (see Figure 7 );

[0029] The edge of the forging upper die 1 is provided with a concave ring lock 7, and the edge of the forging lower die 2 is a convex ring lock 8 that cooperates with the concave ring lock 7 (see Image 6 , Figure 7 ); and the lower forging die 2 is provided with a resistance dam 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com