Electric translation multi-functional jet-irrigating machine with circular rotation cantilever

A circular rotary sprinkler irrigation technology, which is applied in horticulture, botanical equipment and methods, cultivation, etc., can solve the problems of high cost of auxiliary equipment, low degree of automation, thick water pipe diameter, etc., and achieve simple structure, high degree of automation, The effect of avoiding wasting land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

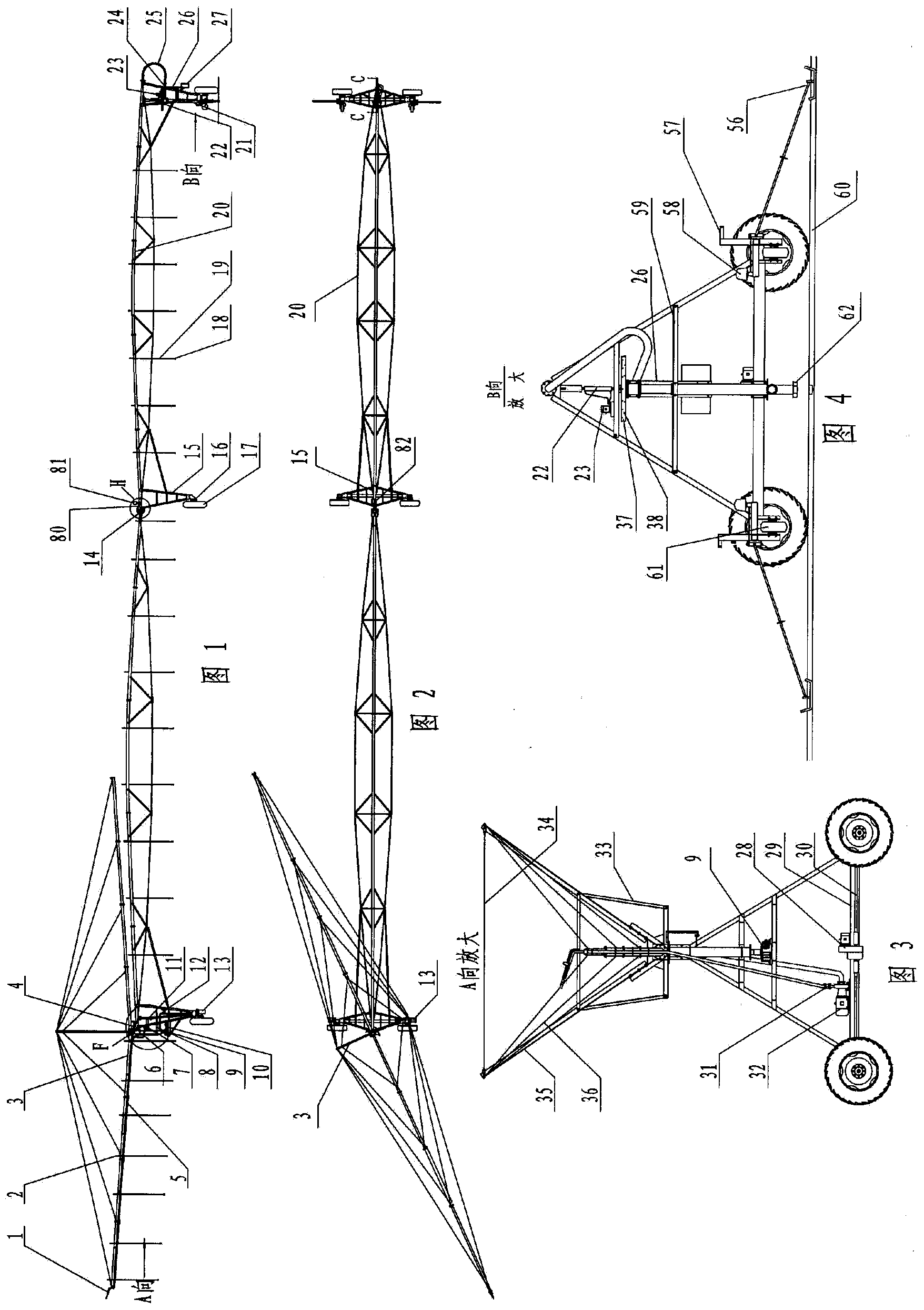

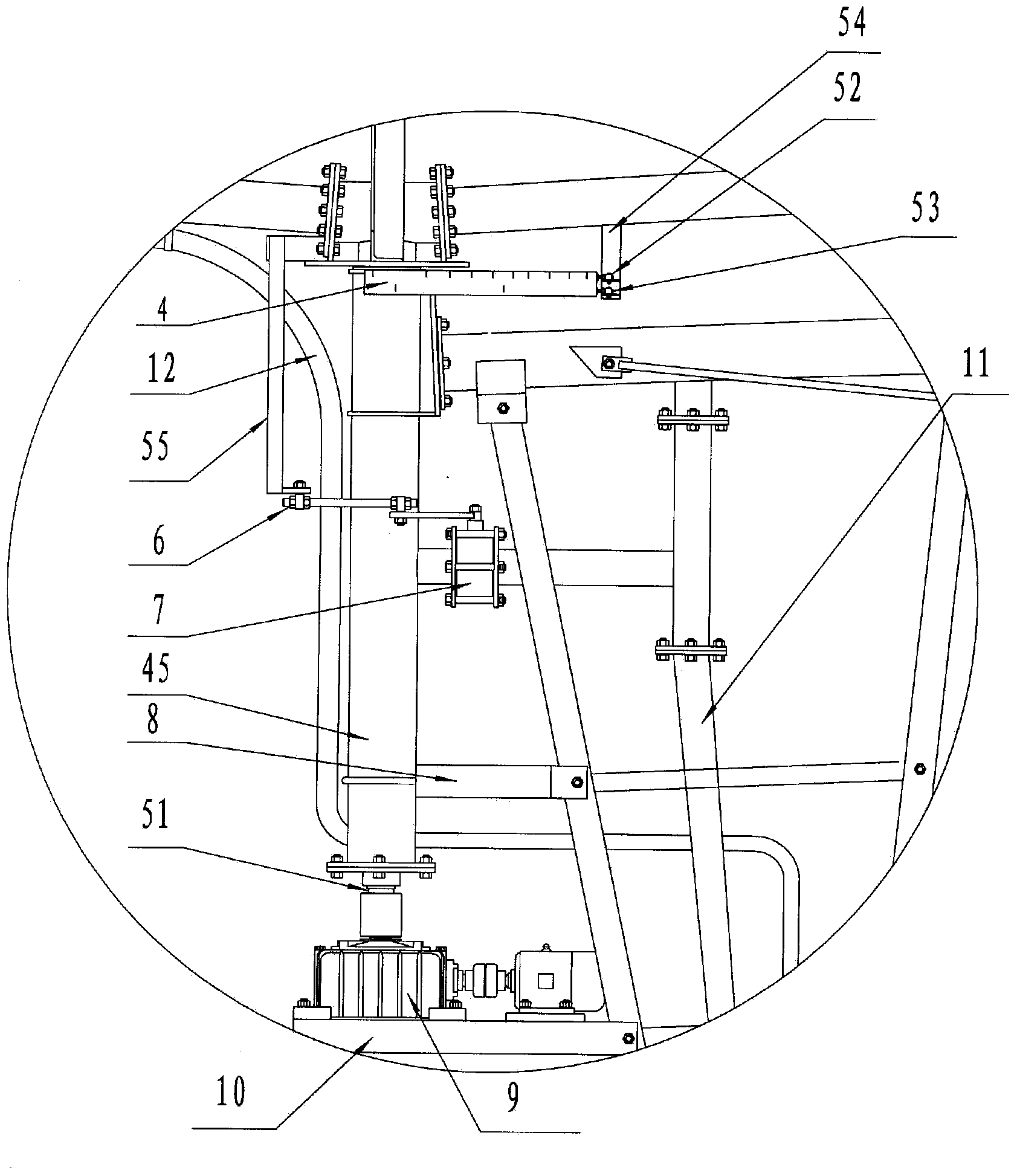

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

[0034] Depend on figure 1 , figure 2 , Figure 4 You can see the overall structure of the sprinkler, which consists of the first-span main control tower car 21, the truss 20, the tower car 15, the rotating cantilever 3, the electric control box 27, the main control panel 37, the rotating cantilever corner control panel 4, The inter-span tower vehicle travel control box 81 and the guide control box 58 are composed; three tower vehicle supports are arranged under the multiple trusses, and the rotating cantilever 3 is connected at the end of the truss; the above-mentioned electric control box, main control panel, and inter-span tower The trolley walking control box and the guide control box constitute the control system of the sprinkler;

[0035] Depend on figure 1 , Figure 4 , Figure 9It can be seen that the above-mentioned main control tower vehicle 21 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com