Preparation method of resistance switch adopting TiO2/SnO2 composite nano-rods

A resistance switch and nanorod technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of rapid disappearance of materials and continuous refresh, achieve good room temperature resistance switching characteristics, reduce recombination, and large resistance switching effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

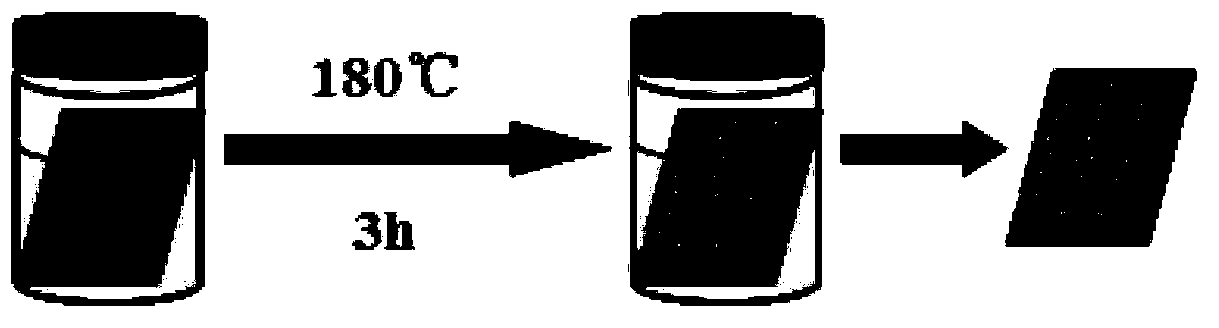

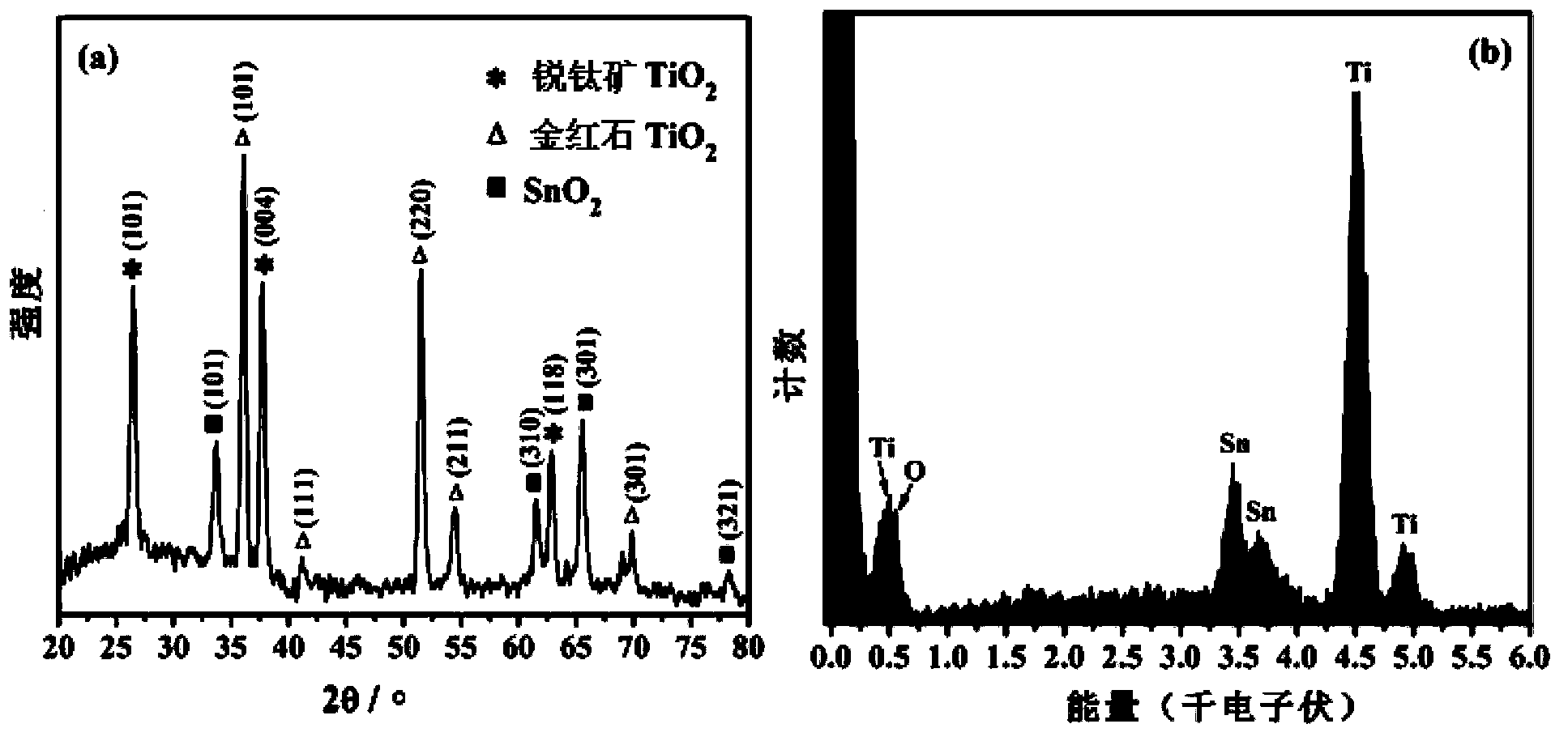

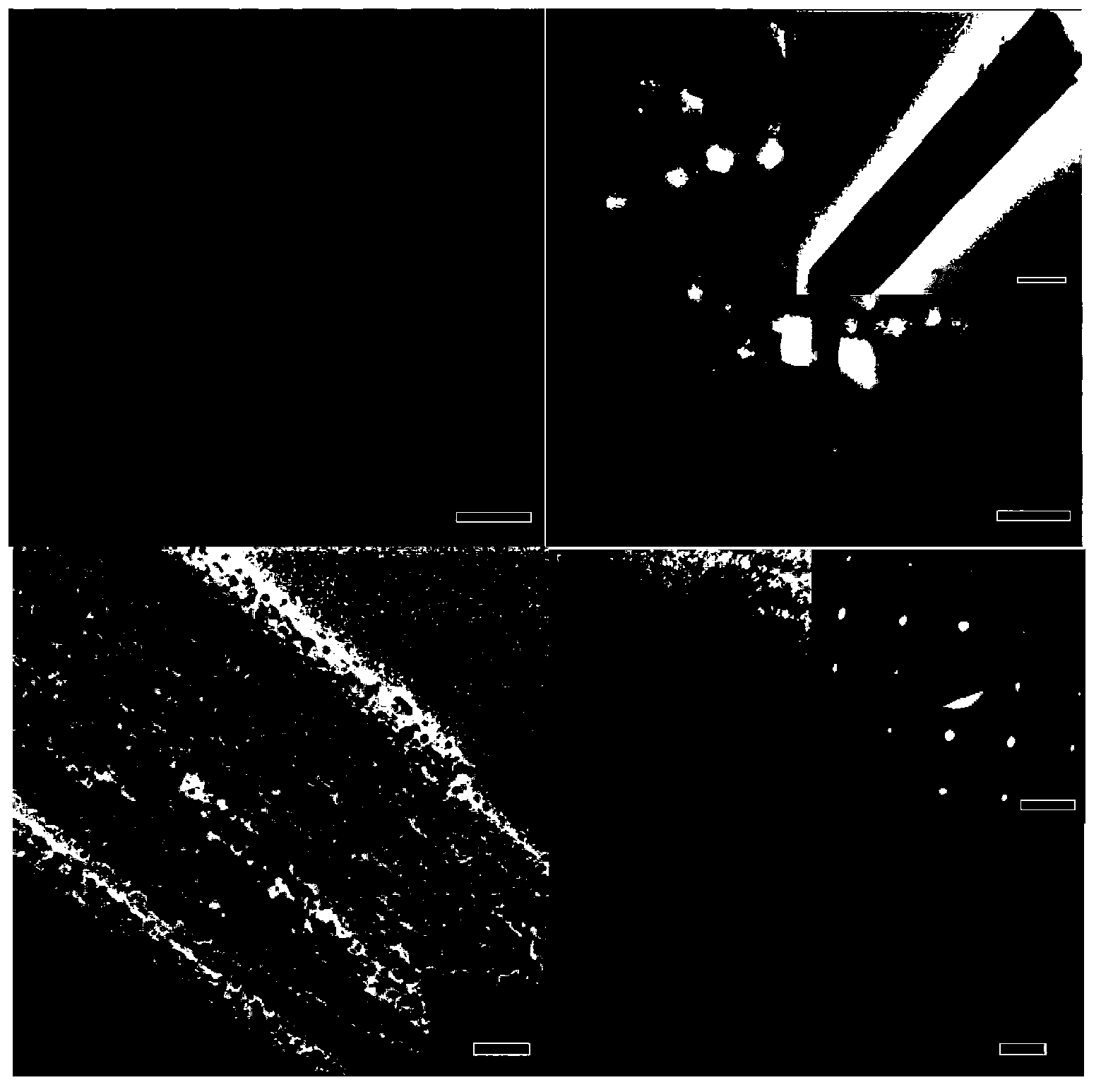

[0025] figure 1 For the embodiment, directly grow TiO on the conductive substrate by hydrothermal method 2 / SnO 2 Schematic illustration of composite nanorod arrays, as figure 1 As shown, the TiO in this example 2 / SnO 2 A preparation method for a composite nanorod resistance switch, comprising the following steps:

[0026] 1) Weigh 200 μL of tetraisopropyl titanate and 7 mL of concentrated hydrochloric acid (12mol / L) and dissolve them in 6.5 mL of deionized water, then add an appropriate amount of SnCl at a molar ratio of 1:1 4 ·5H 2 0, stirred to form a mixed solution, and transferred the mixed solution to a 50mL reaction kettle with a polytetrafluoroethylene liner; then the cleaned FTO conductive glass (with an area of about 3cm 2 , followed by ultrasonic cleaning with acetone, ethanol, and deionized water) were inserted into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com