Rust removal oiler for steel rail

A rust remover and oiler technology, which is applied to tracks, track laying, track maintenance, etc., can solve the problems of endangering driving safety, difficult to implement, weakening the strength of steel rails, etc., and achieves convenient use, good effect, and fast rust removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

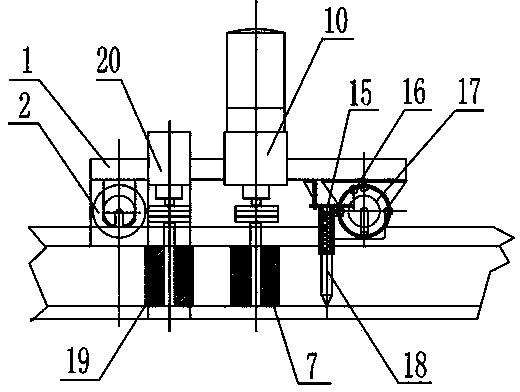

[0010] A rail derusting and oiling machine, comprising a frame 1, a traveling wheel, a generator 11, an oiling or spraying device, and a dust collection device, characterized in that rolling pins are evenly arranged on the outer surface of the front traveling wheel 17 of the frame 1 16. A rust cutting knife 18 is installed on the frame 1 at the rear end of the front traveling wheel 17, and a spring 15 is set on the upper half of the rust cutting knife 18. When the wheel 17 moved forward, after the rolling pin 16 contacted the rust-cutting knife 18, the rust-cutting knife 18 was lifted, and then the rolling pin 16 broke away from the rust-cutting knife 18, and the rust-cutting knife 18 hit the track under the action of the spring 15, and the The thicker rust blocks on the track are loosened to facilitate the rolling brush of the steel wire; rust removers are installed above the walking wheels at both ends of the frame 1, and there are two types of rust removers: vertical and hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com