Yarn tension constant device

A technology of yarn tension and yarn guide hook, which is applied in the direction of textiles and papermaking, etc. It can solve the problems that the yarn tension cannot be precisely controlled, it is difficult to achieve constant tension, and the size of the tension cannot be adjusted, so as to achieve constant tension, constant torque, Exactly consistent yarn tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

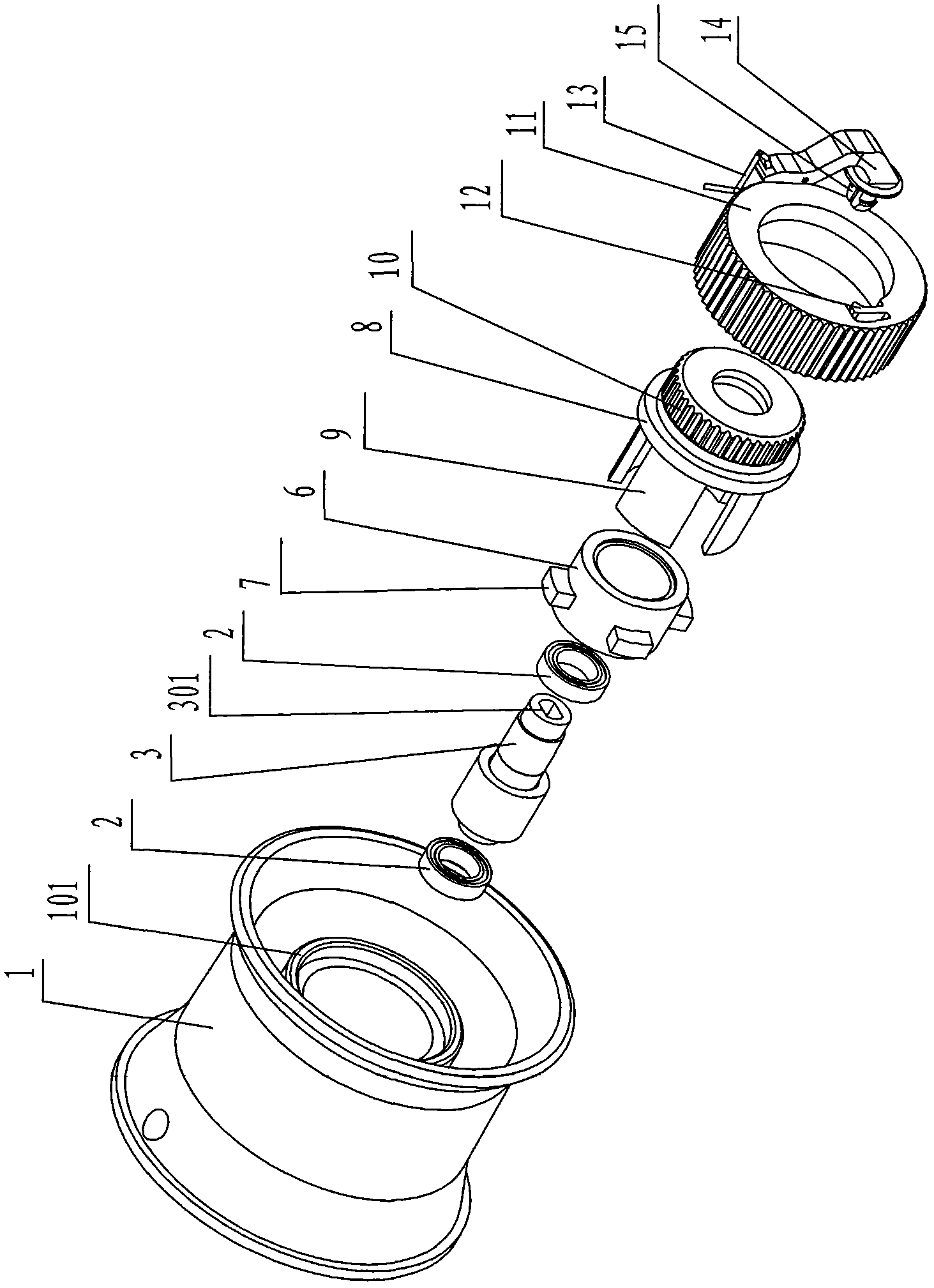

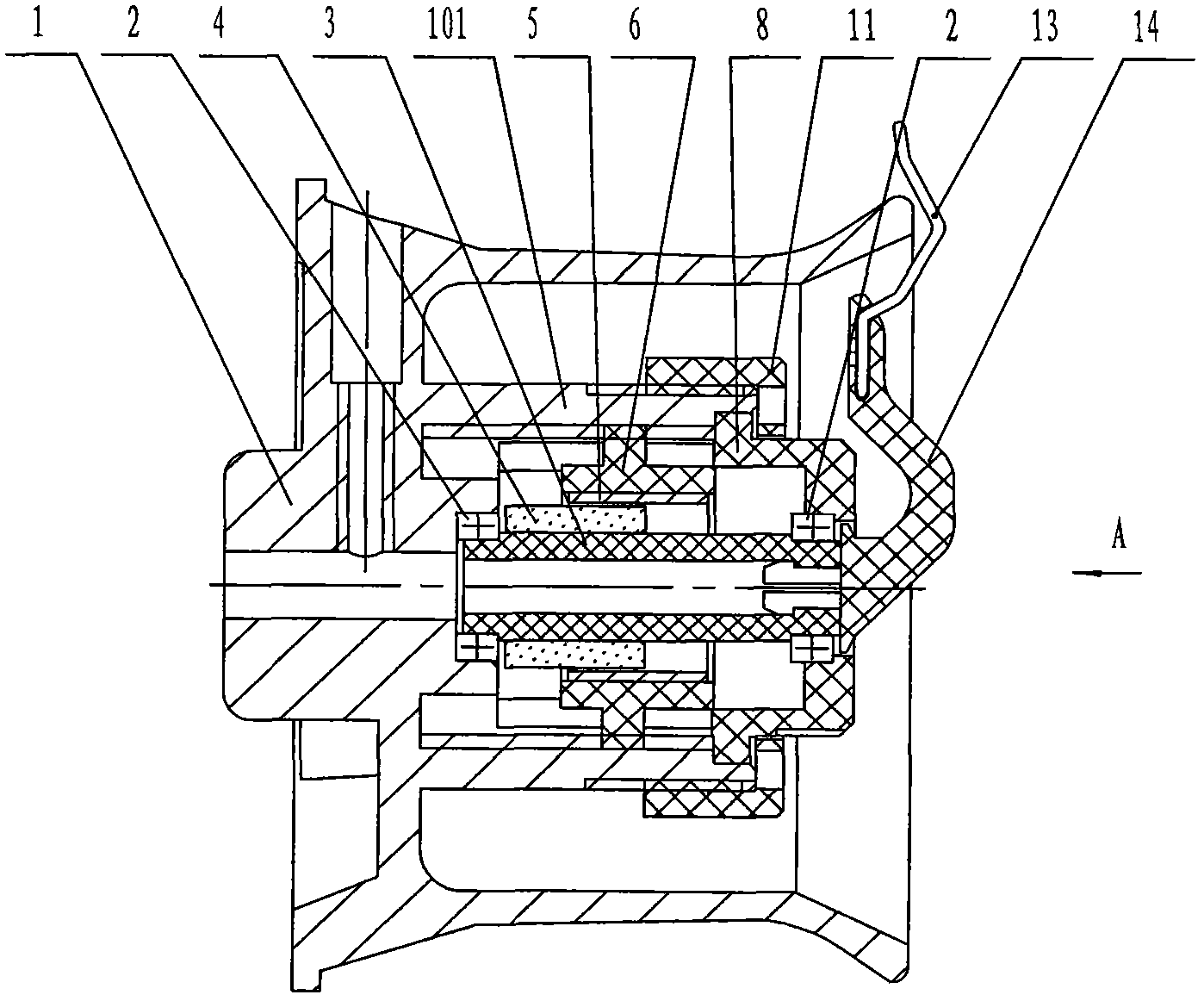

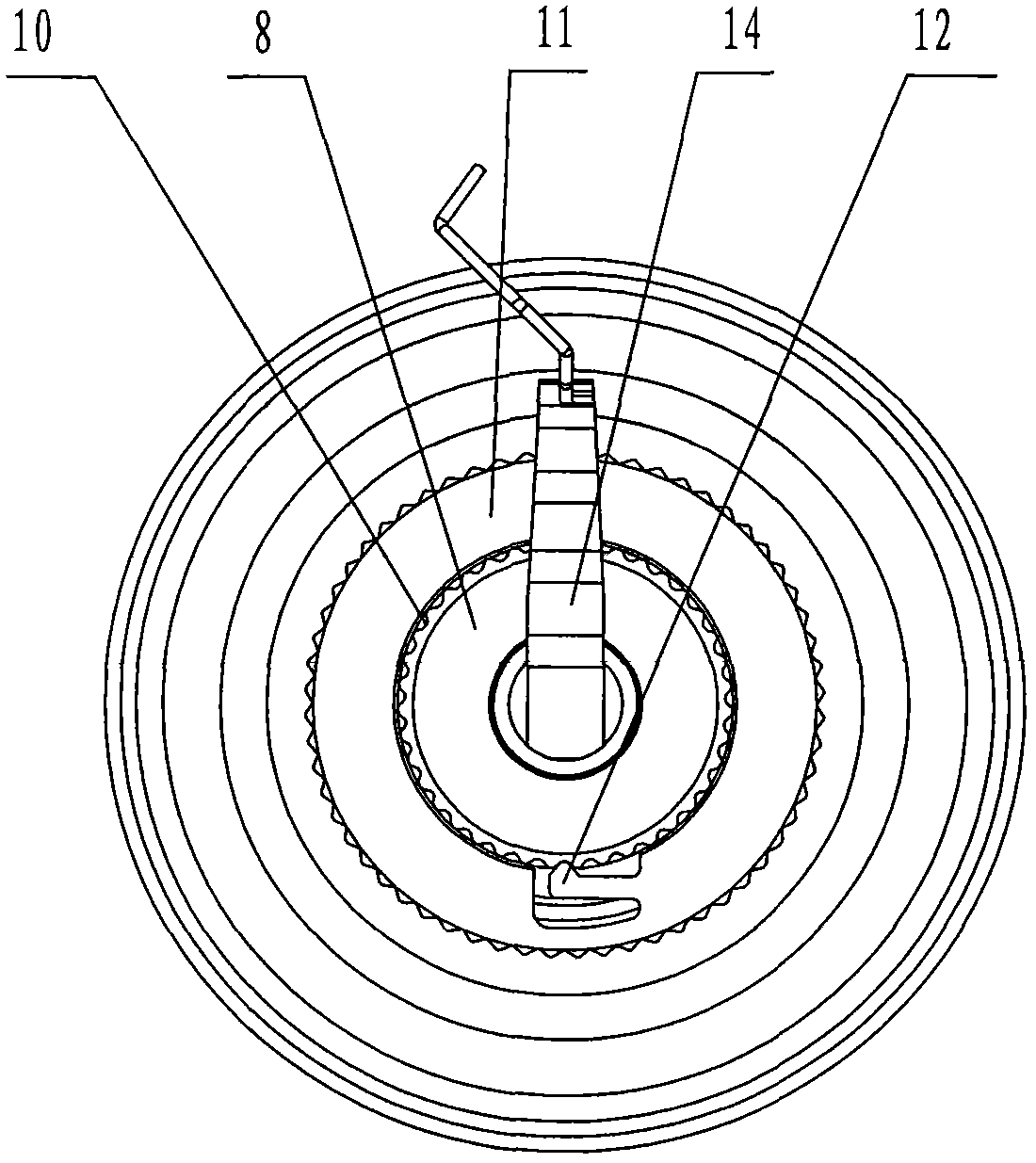

[0022] As shown in the figure, the present invention mainly consists of a roller 1, a mandrel 3, a magnetic sleeve 4, a hysteresis sleeve 5, a sleeve 6, an adjustment disc 8, an annular locking cover 11 and a guide hook 13. The bottom of the inner cavity of the roller 1 is fixedly provided with a cylinder bracket 101 coincident with its axis. The inner wall of the cylinder bracket 101 has internal threads, and the outer edge has external threads; there is a shaft hole on the adjustment disc 8; the mandrel 3 passes through the bearing 2 Installed in the cylindrical support 101, the rear end is located on the body of the roller 1 at the bottom of the inner cavity of the cylindrical support 101, the front end is located on the shaft hole of the adjustment disc 8, the mandrel 3 is driven by the motor; the magnetic sleeve 4 is fixed on the core On the rear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com