Method for determining bending angle of each pass of cold roll forming of plate and strip

A technology of bending angle and cold-bending forming, which is applied in the field of determining the bending angle of each pass of cold-bending forming of plates and strips. It can solve the edge wave shape, failure to consider the influence of plate and strip deformation, and plate and strip warping, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A method for determining the bending angle of each pass of cold-bending forming of a plate and strip. The concrete steps of this method are:

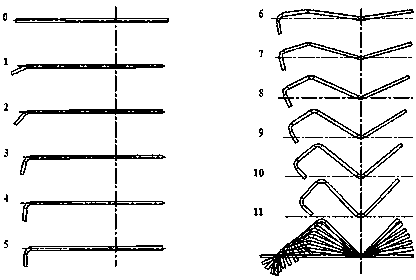

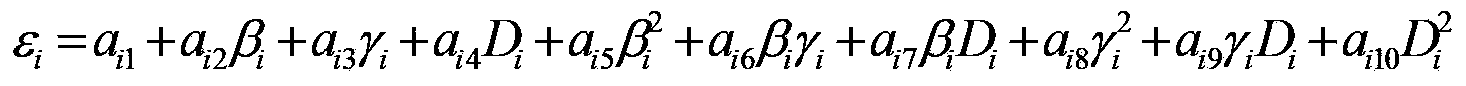

[0059] The first step, the design of the virtual test plan

[0060] According to the shape factor function, set the number of cold-bending passes n of the asymmetric Z-shaped steel to 11, and complete as follows figure 1 The design of the roller flower diagram is shown. This step takes the 7th pass as an example, select the first bending angle β of the 7th pass 7 , the second bending angle γ 7 and roll work roll diameter D 7 As a test factor; each test factor takes three horizontal values, that is, the first bending angle β 7 The values are 16°, 23° and 30° respectively, the second bending angle γ 7 The values are 6°, 12° and 18° respectively, and the working roll diameter of the roll is D 7 The values are 320mm, 400mm and 480mm respectively; according to the orthogonal table L 9 (3 4 ) to determine the virtual tes...

Embodiment 2

[0122] A method for determining the bending angle of each pass of cold-bending forming of a plate and strip. The specific steps of the method are: the first step, the design of the virtual test program

[0123] According to the production experience, it is preliminarily determined that the number n of cold bending passes of the asymmetric Z-shaped steel is 12, and the design of the roll pattern is completed accordingly. In this step, take the 6th pass as an example, select the first bending angle β of the 6th pass 6 , the second bending angle γ 6 and roll work roll diameter D 6 As a test factor; each test factor takes three horizontal values, that is, the first bending angle β 6 The values are 16°, 21° and 26° respectively, the second bending angle γ 6 6°, 11° and 16° respectively, the working roll diameter of the roll is D 6 320mm, 380mm and 440mm respectively; according to the orthogonal table L 9 (3 4 ) to determine the virtual test plan for each test factor and co...

Embodiment 3

[0187] A method for determining the bending angle of each pass of cold-bending forming of a plate and strip. The concrete steps of this method are:

[0188] The first step, the design of the virtual test plan

[0189] According to the shape factor function, the number n of cold bending passes of the asymmetric Z-shaped steel is set to 10, and the design of the roll pattern is completed accordingly. Select the bending angle of the plate and strip of each pass and the diameter of the work roll of the roll as the test factors, and pre-select the level values of each test factor. In this step, the third pass is taken as an example, and the first bending angle β is selected. 3 and roll work roll diameter D 3 is the test factor; each test factor takes three horizontal values, that is, the first bending angle β 3 16°, 22° and 28° respectively, the working roll diameter of the roll is D 3 400mm, 450mm and 500mm respectively; according to the orthogonal table L 9 (3 4 ) to dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com