Method for using plants to control and restore soil and to generate biological fuel

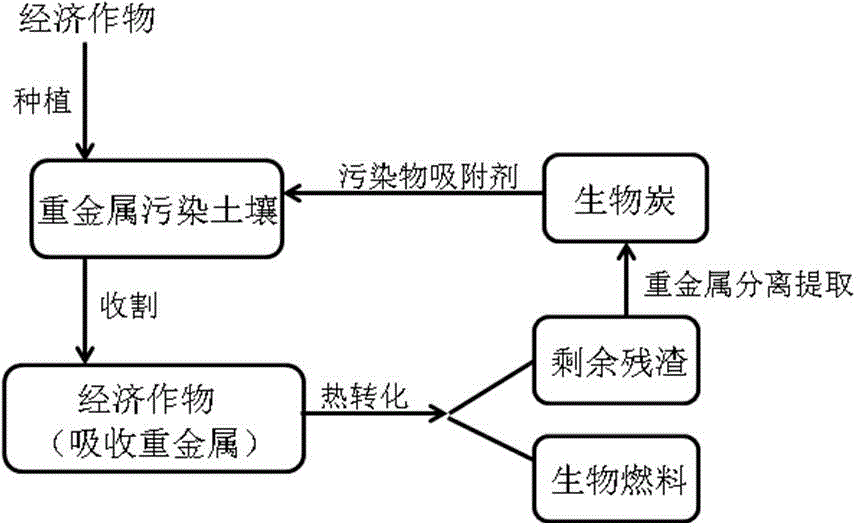

A technology for biofuels and soil remediation, which is applied to the restoration of biofuels, polluted soils, and the preparation of liquid hydrocarbon mixtures, can solve the problems of singleness, low economic benefits, and long time consumption, and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Planting: planting bamboo on the soil of the polluted cadmium ore metal mining area; planting by transplanting. Plant according to the general planting method of bamboo.

[0020] Plant Harvesting: Harvesting is carried out by mechanized method after 3-5 years of transplanting.

[0021] Post Harvest Plant Treatment:

[0022] The harvested bamboo is cut into long sections of 0.5-1.0m, put into a fixed-bed pyrolysis furnace, and pyrolyzed at 400-600°C for 1-6h to obtain biochar and pyrolysis oil. The pyrolysis oil is passed through indirect heat exchange The pyrolysis oil is collected by cooling, and the pyrolysis oil is further catalytically hydrogenated to obtain biofuel oil. The yield of bio-oil can reach 40-70% of the mass of the original material. Catalytic hydrogenation steps and conditions: Take 200ml of pyrolysis oil and put it into a pressurized container tank with a volume of 500ml with stirring and water cooling functions, and add 5-10g of Co-Mo-P catalyst and...

Embodiment 2

[0025] Planting: planting sugarcane on the soil of the polluted tungsten ore metal mining area; planting by transplanting. Cultivation is carried out according to the general cultivation method of sugar cane.

[0026] Plant Harvesting: Harvesting is carried out by mechanized method 1 year after transplanting.

[0027] Post Harvest Plant Treatment:

[0028] The harvested sugarcane is cut into 0.5-1.0m long sections, placed in a fixed-bed pyrolysis furnace, and pyrolyzed at 400-600°C for 1-6 hours to obtain biochar and pyrolysis oil. The pyrolysis oil is passed through indirect heat exchange The pyrolysis oil is collected by cooling, and the pyrolysis oil is further catalytically hydrogenated to obtain biofuel oil. The yield of bio-oil can reach 40-70% of the mass of the original material. Catalytic hydrogenation steps and conditions: Take 200ml of pyrolysis oil and put it into a pressurized container tank with a volume of 500ml with stirring and water cooling functions, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com