Sweet potato stem leaf polyphenol and preparation method thereof

A technology of sweet potato stems and leaves and sweet potatoes, applied in the field of sweet potato stems and leaves polyphenols and its preparation, can solve the problems of discarding and waste of resources, and achieve the effects of low production cost, strong antioxidant activity, and high commercial application development value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

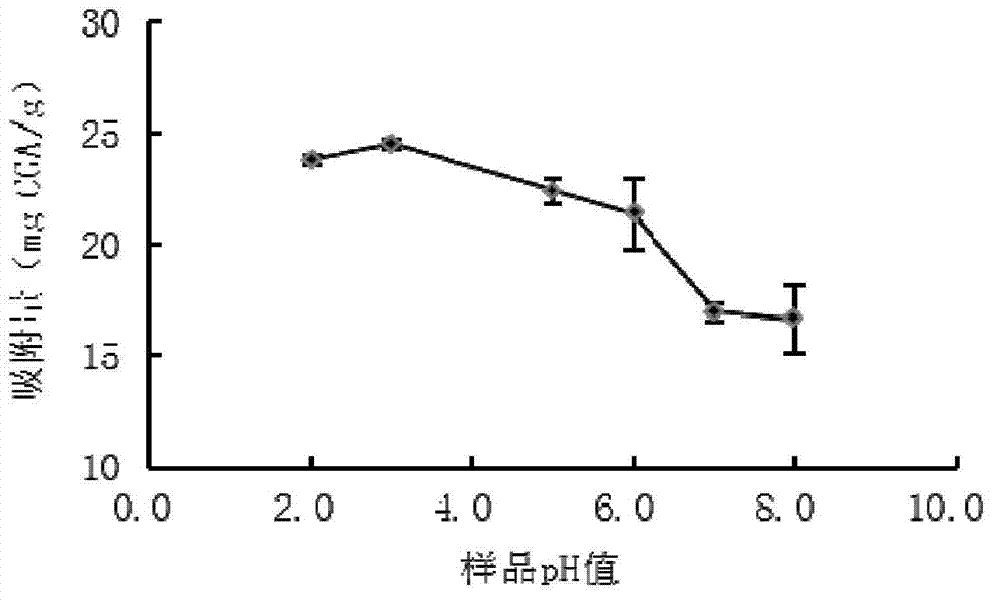

[0043] Embodiment 1, the influence of the pH value of polyphenol crude extract on the adsorption capacity of AB-8 macroporous adsorption resin

[0044] (1) Collection and pretreatment of raw materials: The sweet potato stems and leaves were picked in late July, and the picking part was the top 10cm of the vines. Wash and drain the fresh sweet potato stems and leaves, cut them into 1cm pieces, put them in a tray and pre-freeze them in a -40°C refrigerator for 24 hours, take them out and put them in a freeze dryer, dry them for 48 hours, and use a universal grinder Pulverize, cross 40 mesh sieves, make sweet potato stem and leaf dry powder, as following experimental raw material;

[0045] (2) Crude extraction of polyphenols: Weigh 0.5g of sweet potato stem and leaf dry powder in step (1), add 10mL of 70% ethanol solution according to the ratio of solid to liquid 1:20, mix well, and ultrasonically extract in an ultrasonic cleaning machine 30min, after extraction, centrifuge at 7...

Embodiment 2

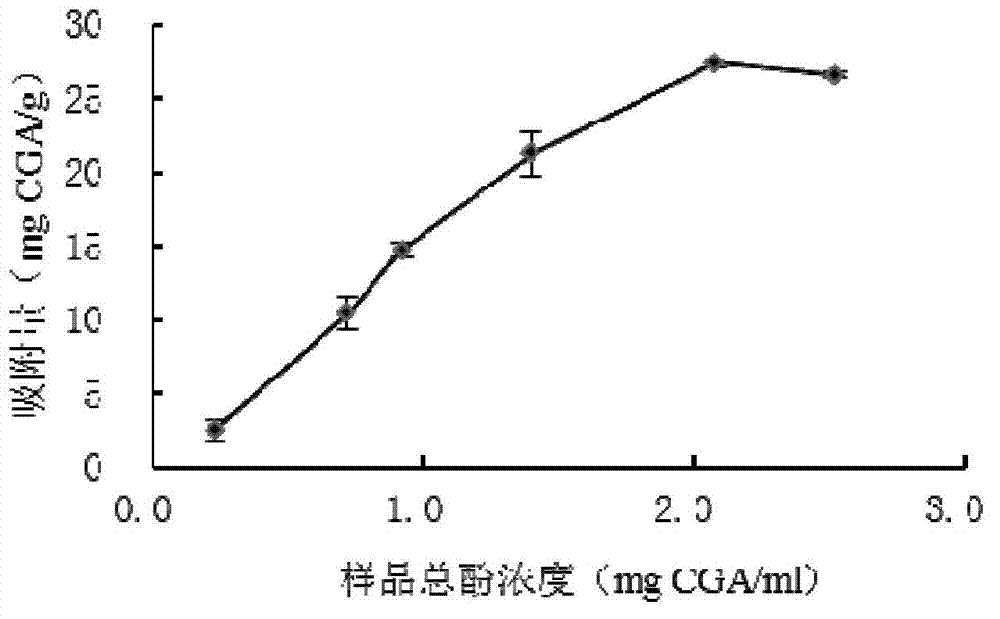

[0056] Embodiment 2, the influence of polyphenol crude extraction total phenol concentration on the adsorption capacity of AB-8 macroporous adsorption resin

[0057] According to the steps (1) and (2) in Example 1, adjust the total phenol concentration of each solution to 0.02, 0.50, 1.00, 1.50, 2.00 and 2.50 mg CGA / mL with distilled water, and fix the pH value of each solution to 3, Adsorption was carried out according to the method of step (3) of Example 1, and the influence of different total phenol concentrations in the crude extract on the adsorption capacity of the resin was investigated.

[0058] The result is as image 3 As shown in Table 2, it can be seen that when the total phenol concentration of the crude polyphenol extract is lower than 2.00mg CGA / mL, the resin adsorption capacity increases with the increase of the sample concentration, and the resin reaches the maximum adsorption when the sample concentration is 2.00mg CGA / mL The amount of CGA / g was 27.38mg CGA / ...

Embodiment 3

[0061] Embodiment 3, the influence of ethanol desorption liquid mass concentration on the desorption rate of AB-8 macroporous adsorption resin

[0062] According to the steps (1) and (2) in Example 1, the crude extract of sweet potato stem and leaf polyphenols was prepared, and the pH value of the solution was adjusted to 3.0, and the total phenol concentration was 2.00 mg / mL for later use. Adsorb according to the method of step (3) of Example 1. After the adsorption is saturated, wash away impurities with an appropriate amount of distilled water, add 50 mL of ethanol desorption solution with a concentration of 30, 50, 70, 90, and 100% respectively, and place in a constant temperature oscillator. Desorb each resin by shaking at 25°C and 130r / min for 24 hours, measure the total phenol concentration in the desorption solution, and calculate the desorption rate according to the following formula. The influence of different concentrations of ethanol desorption solution on the deso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com