Additive for limestone-gypsum wet method flue gas desulphurization

A wet flue gas desulfurization and additive technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of long duration of action, slow onset time, and short duration, and achieves less usage. , The effect of promoting grain formation and improving crystallization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

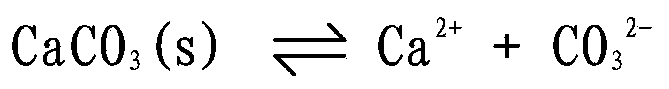

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The components of the desulfurization additive and the weight percentage of each component are:

[0041] (Total weight is 100Kg)

[0042] Component

Sodium carboxymethyl cellulose

Aluminum sulfate

Ferric sulfate

Copper sulfate

Manganese sulfate

Weight (kg)

60

30

2

1

3

2

2

Weight percentage (%)

60

30

2

1

3

2

2

[0043] The method of using desulfurization additives is as follows:

[0044] a. The above-mentioned raw materials are compounded in proportion to form a finished product, and then added to the absorption tower. The initial addition amount is 0.6‰ of the weight of the limestone slurry;

[0045] b. After the desulfurization system has been running for a period of time, supplement it according to the loss of additives.

[0046] Apply the above desulfurization additives to the inlet flue gas SO 2 The design value of the concentration is 1584mg / Nm 3 In the desulfurization system, the inlet flue gas SO o...

Embodiment 2

[0048] The components of the desulfurization additive and the weight percentage of each component are:

[0049] (Total weight is 100Kg)

[0050] Component

Sodium carboxymethyl cellulose

Aluminum sulfate

Ferric sulfate

Manganese sulfate

Weight (kg)

30

50

10

5

2

3

Weight percentage (%)

30

50

10

5

2

3

[0051] The method of using desulfurization additives is as follows:

[0052] a. The above-mentioned raw materials are mixed in proportion to form a finished product, and then added to the absorption tower. The initial addition amount is 0.4‰ of the weight of the limestone slurry;

[0053] b. After the desulfurization system has been running for a period of time, supplement it according to the loss of additives.

[0054] Apply the above desulfurization additives to the inlet flue gas SO 2 The design value of the concentration is 1584mg / Nm 3 In the desulfurization system, the inlet flue gas SO of the desulfurization syste...

Embodiment 3

[0056] The components of the desulfurization additive and the weight percentage of each component are:

[0057] (Total weight is 100Kg)

[0058] Component

Sodium carboxymethyl cellulose

Aluminum sulfate

Ferric sulfate

Weight (kg)

40

35

12

10

3

Weight percentage (%)

40

35

12

10

3

[0059] The method of using desulfurization additives is as follows:

[0060] a. The above-mentioned raw materials are compounded in proportion to form a finished product, which is added to the absorption tower, and the initial addition amount is 0.5‰ of the weight of the limestone slurry;

[0061] b. After the desulfurization system has been running for a period of time, supplement it according to the loss of additives.

[0062] Apply the above desulfurization additives to the inlet flue gas SO 2 The design value of the concentration is 1584mg / Nm 3 In the desulfurization system, the inlet flue gas SO of the desulfurization system 2 The actual va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com