Motor rotor and motor with same

A technology of motor rotor and rotor iron core, applied in the direction of magnetic circuit rotating parts, DC commutator, electrical components, etc. problems such as failure to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions and other beneficial effects of the present invention will be made obvious by describing the specific embodiments of the present invention in detail below in conjunction with the accompanying drawings.

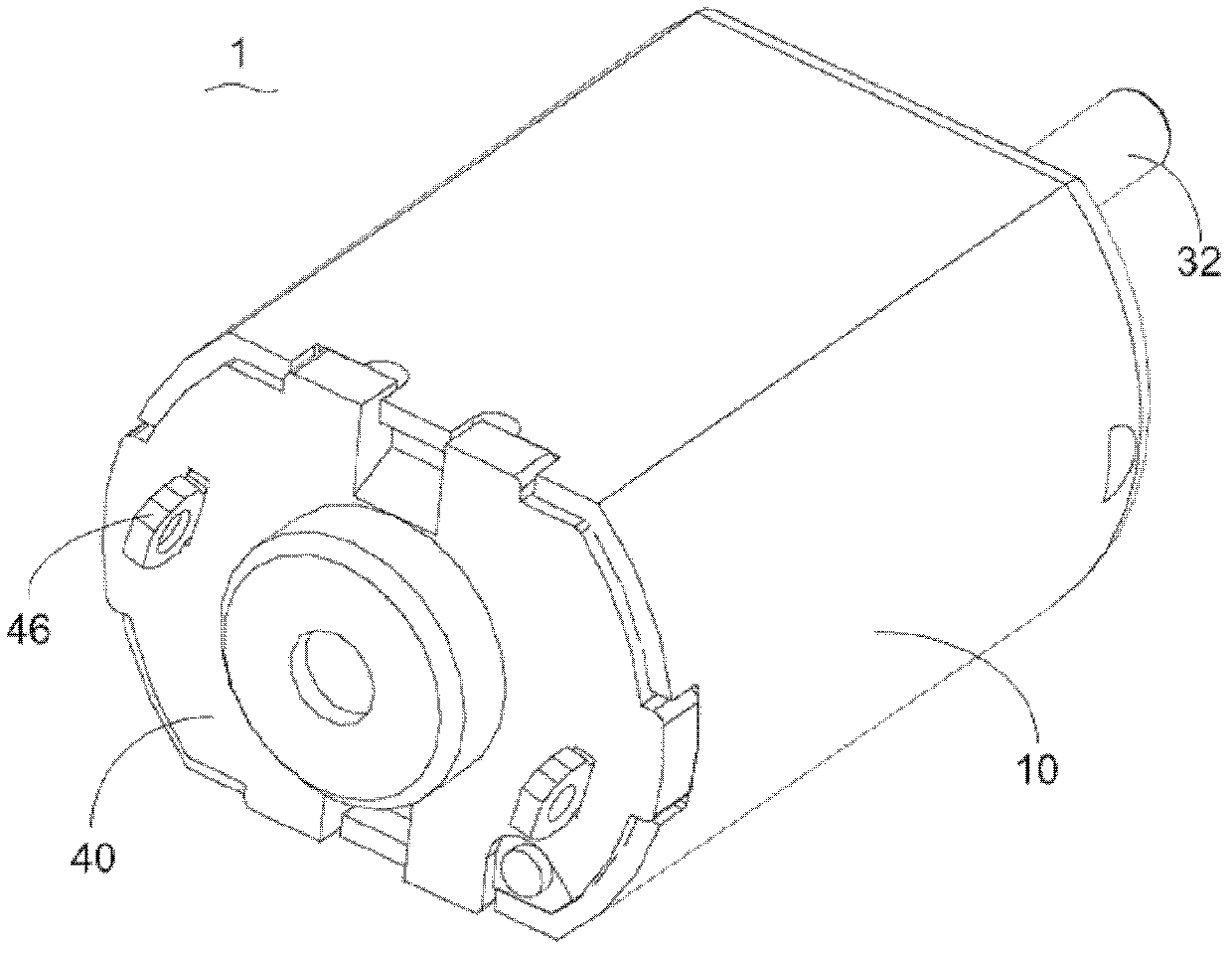

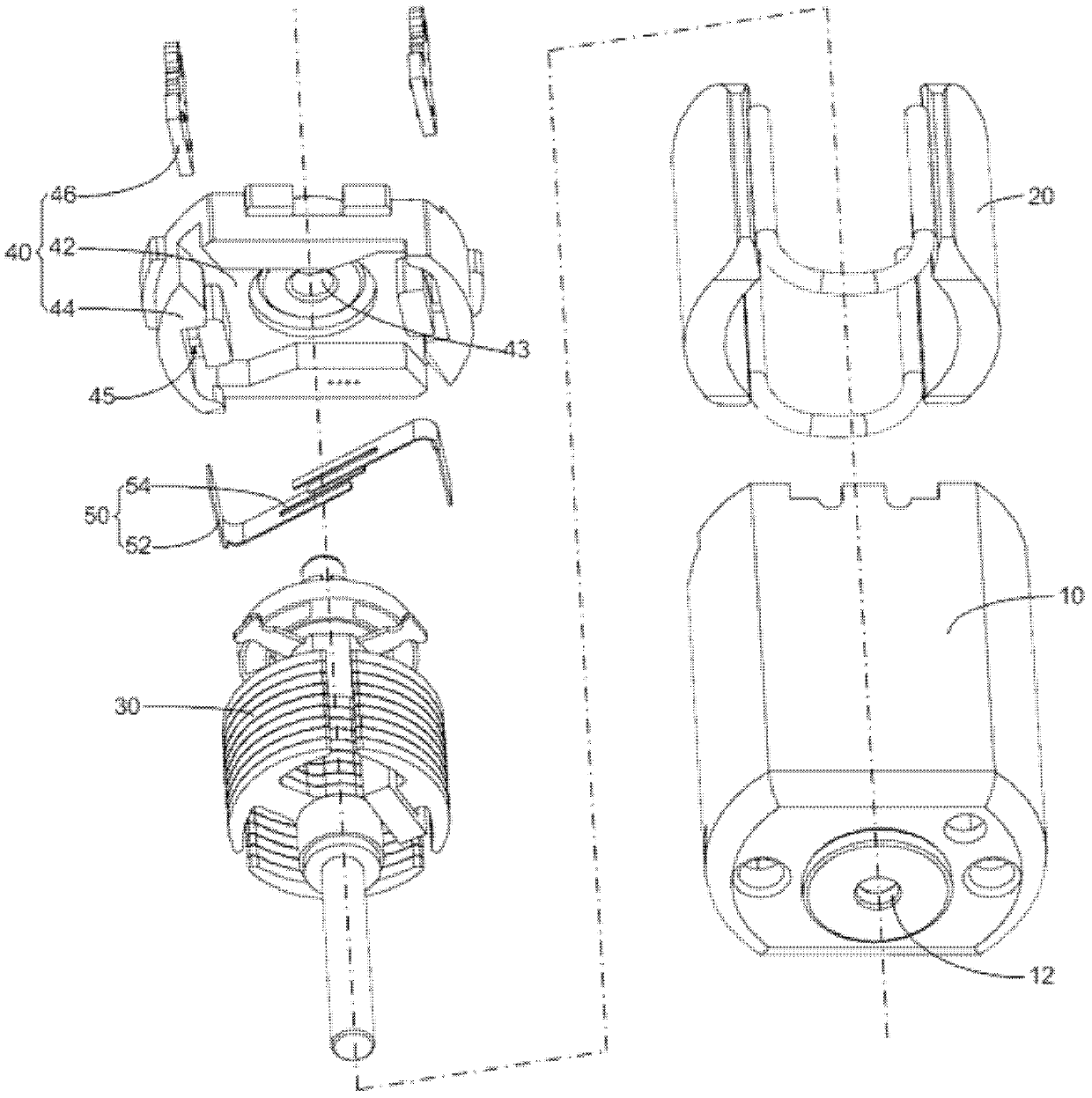

[0016] See figure 1 and figure 2 The motor 1 of the preferred embodiment of the present invention includes a housing 10, a plurality of permanent magnets 20, a rotor 30, an end cover 40 and a plurality of brushes 50.

[0017] The housing 10 is roughly cup-shaped, and a first through hole 12 for accommodating a bearing is opened at the bottom. The permanent magnet 20 is approximately in the shape of a curved sheet and is fixed to the inner wall of the housing 10 to form a space for accommodating the rotor 30.

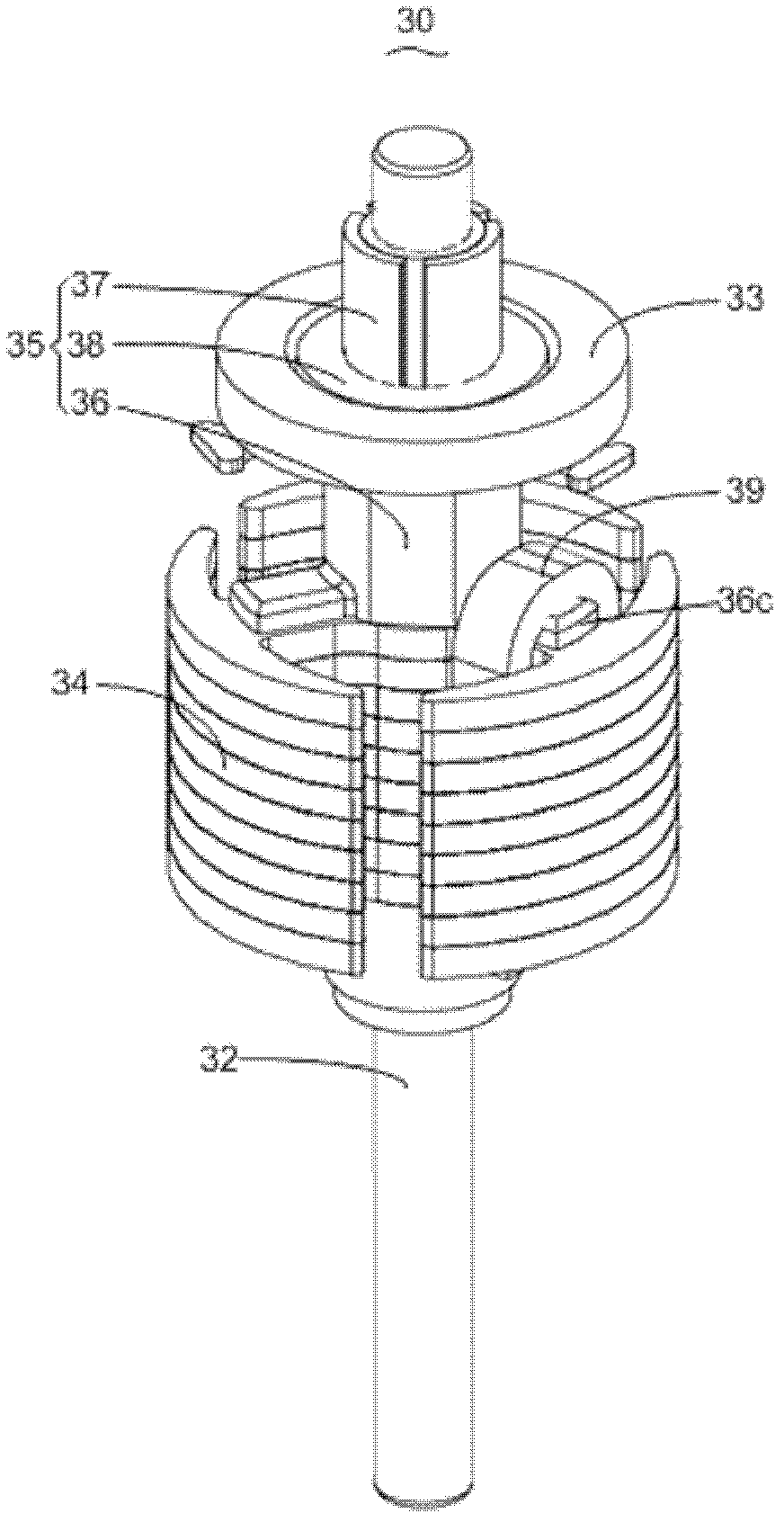

[0018] Please combine Figure 3 to Figure 5 The rotor 30 includes a rotating shaft 32, a rotor core 34, a commutator 35 and a plurality of coils 39 (only one coil is shown in the figure).

[0019] The rotor core 34 includes a cylindrical tooth ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com