Pressure sensor

A pressure sensor and signal sensing technology, which is applied in the direction of measuring fluid pressure, instruments, and measuring fluid pressure through mechanical components, etc., can solve the problems of system control misoperation, unstable product performance, unstable product output, etc., to prevent fracture, The effect of reliable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The core of the present invention is to provide a pressure sensor, which is designed to avoid the pressure sensing part from being affected by the high pressure in the inner cavity through structural optimization design.

[0050] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

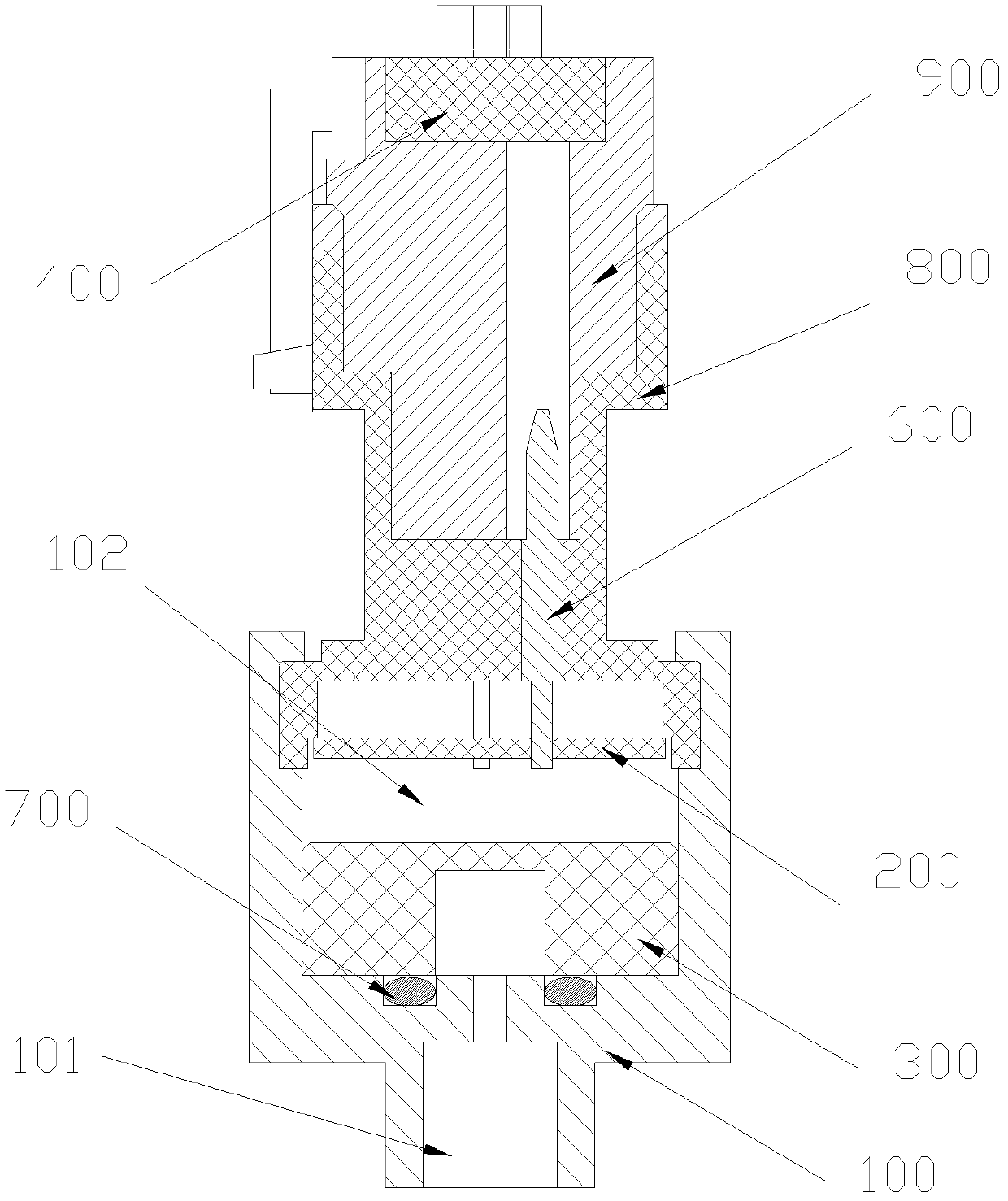

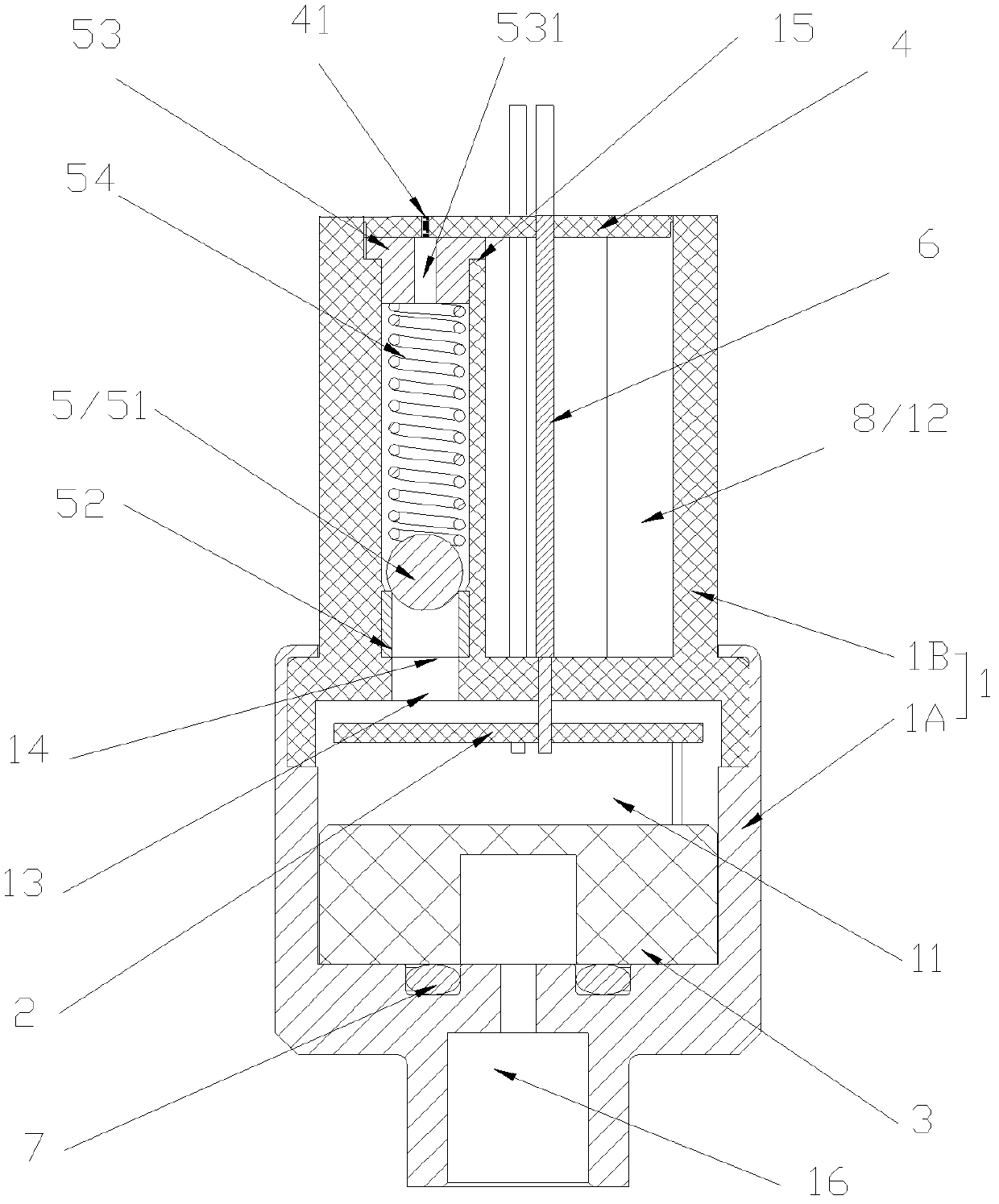

[0051] figure 2 A schematic diagram of the overall structure of a preferred pressure sensor is given for the present invention.

[0052] like figure 2 shown. The pressure sensor includes a substantially cylindrical lower base 1A made of metal material and an upper base 1B made of plastic material. The lower base 1A and the upper base 1B are relatively fixedly connected to form the body 1 of the pressure sensor and form a chamber 11 . A through hole is provided at its bottom as a medium introduction port 16, and the signal sensing part 3 is fixed on the bottom of the chamber 11 of the lower base 1A, and a seal 7 is arranged between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com