Servo minimum pressure valve assembly

A pressure valve, the smallest technology, applied in the direction of inlet pressure control, servo motor components, fluid pressure actuators, etc., can solve problems such as unpredictable fuel systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

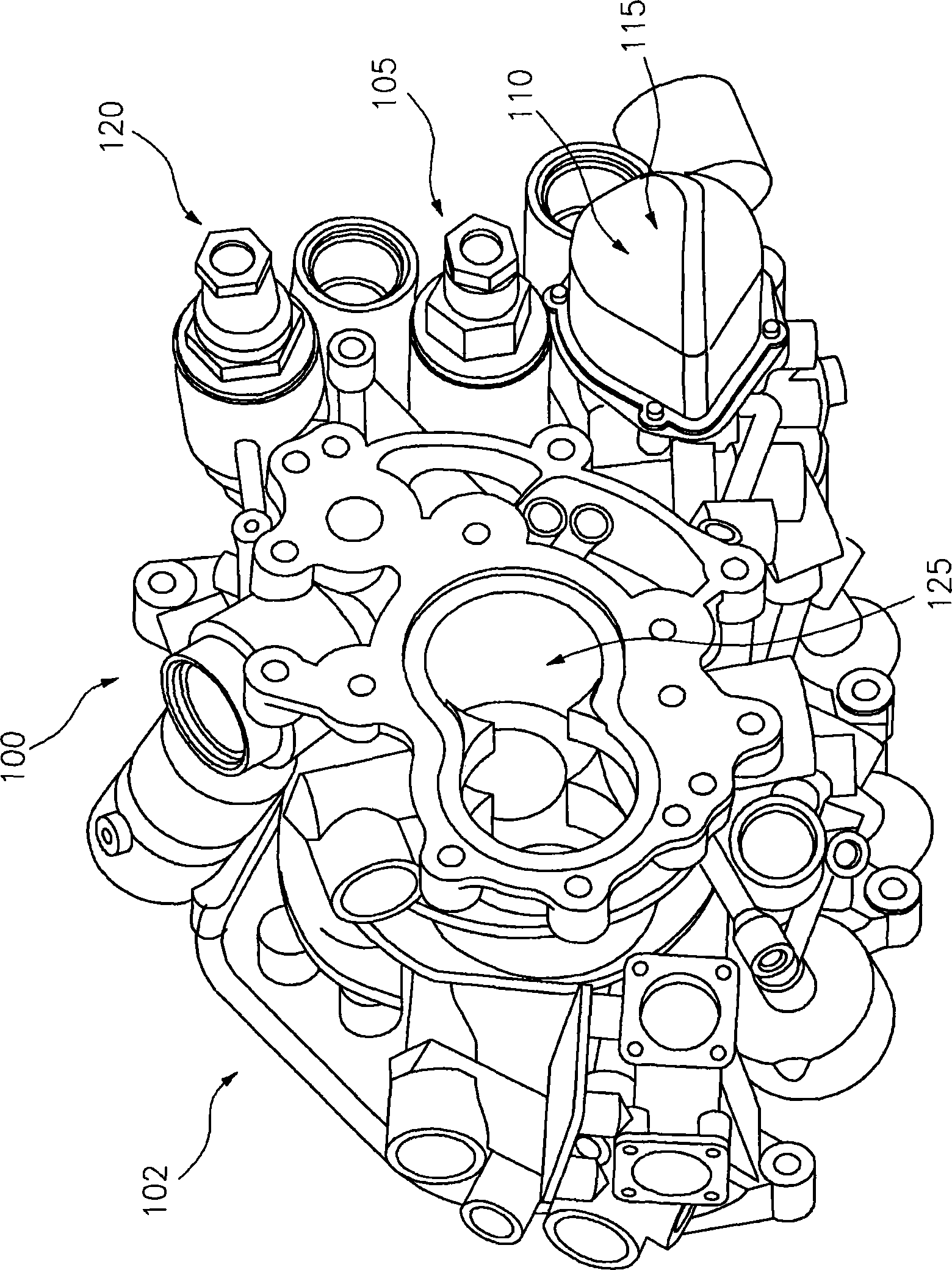

[0012] figure 1 A perspective view of a fuel controller housing portion 100 of a fuel controller 102 for regulating fuel flow in a system, such as an aircraft gas turbine engine, is schematically shown. In one embodiment, fuel controller housing portion 100 includes pressure regulator valve section 105 , metering valve section 110 , containment housing section 115 generally adjacent metering valve section 110 , and servo minimum pressure valve section 120 . Other valves, controls, and feedback features (not shown) may also be included in fuel controller housing portion 100 or in other portions (not shown) of fuel controller 102 . For example, a separate servo pump may be included in fuel controller 102 to generate servo pressure. Fuel flowing into fuel control housing portion 100 is pressurized in pump section 125 . The pressurized flow is metered in metering valve section 110 and then output as fuel combustion flow at metered pressure. The pressure regulating valve section...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap