Printing unit with jet or spray device for cleaning fluid

A technology of printing device and spraying device, applied in printing, printing press, rotary printing press, etc., can solve problems and make effective contributions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

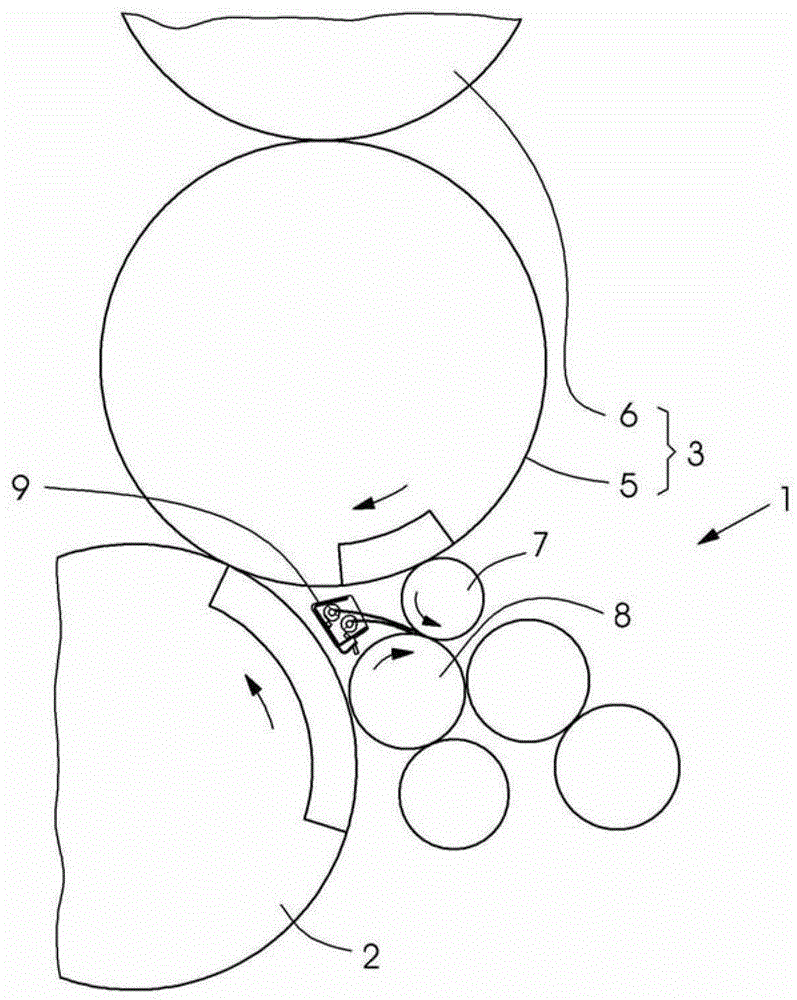

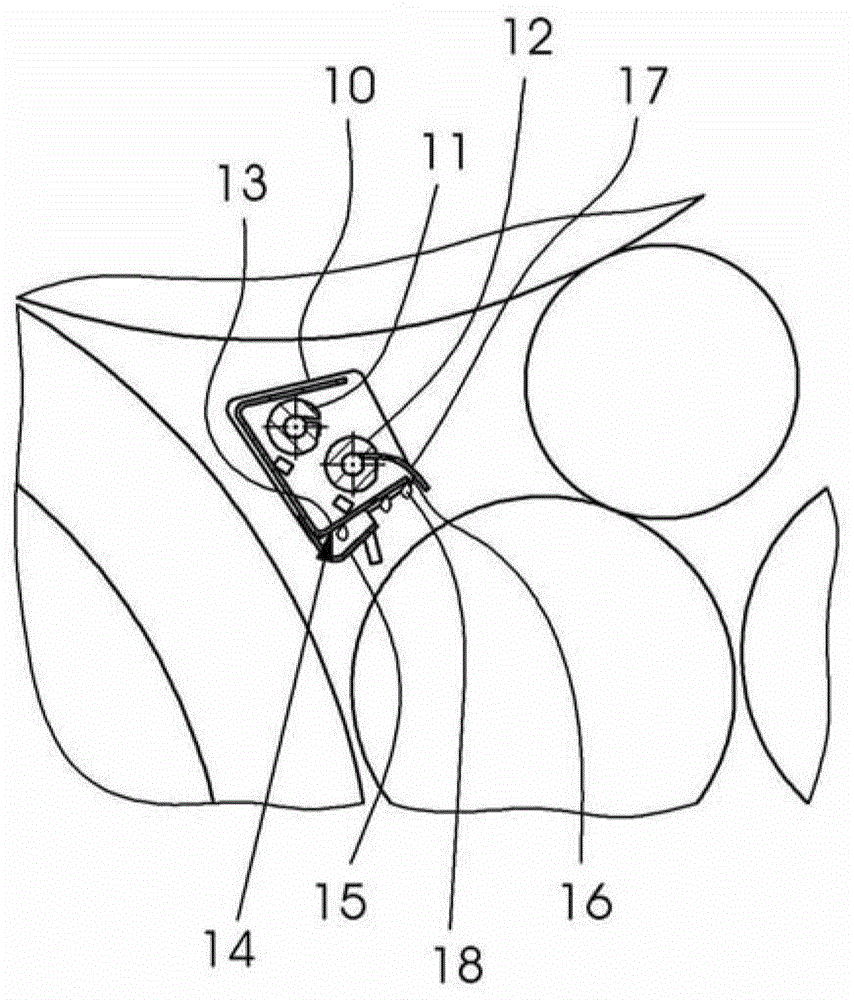

[0024] figure 1 A printing press for offset or planar printing on sheet-fed printing materials is shown in fragments. A printing unit 1 with a printing form cylinder 2 is shown in this partial view. The blanket cylinder and counter-pressure cylinder of the printing unit 1 are not shown. In addition, an anilox inking unit 3 and a dampening unit 4 belong to the printing unit 1 . The anilox roller inking unit 3 comprises an inking roller 5 and an anilox roller 6 . During printing operation, the inking roller 5 rests against the anilox roller 6 and the plate cylinder 2 . The dampening device 4 is not a spray-wetting unit, but a film dampening unit with dip rollers (no reference numerals) for drawing up dampening agent from a dampening box (not shown). Furthermore, the dampening unit 4 comprises a first dampening unit roll 7 and a second dampening unit roll 8 . The first dampening unit roller 7 is a connecting roller for connecting the dampening unit 4 to the anilox roller ink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com